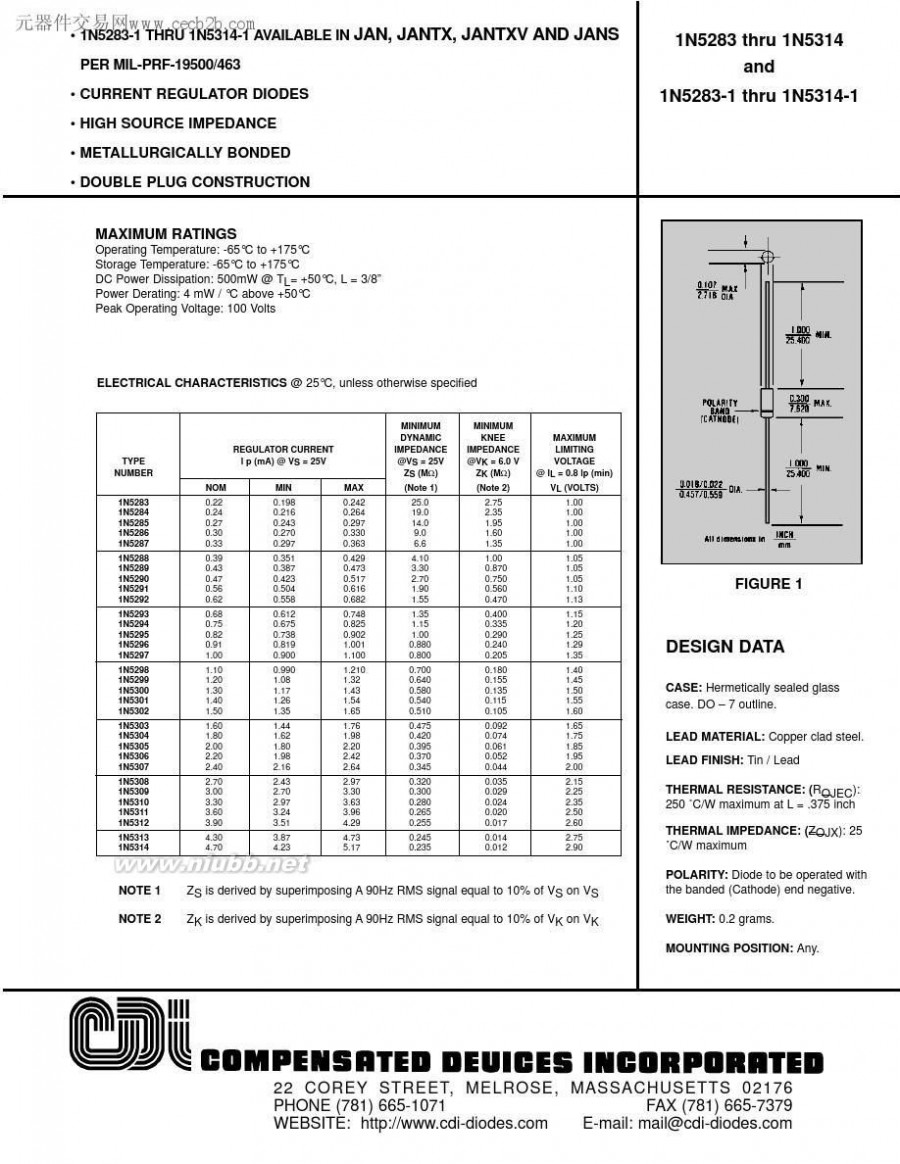

一 : 1N5300-1中文资料

n5300 1N5300-1中文资料

二 : G6K-2F中文资料

F:Outside-L surface mounting terminalG:Inside-L surface mounting terminalP:PCB terminal4.Approved standards

1.Relay function

None:UL, CSA

None:Single-side stable modelDoes not conform to Telcordia specificationsU:Single-winding latching modelY:UL, CSA2.Contact formConforms to Telcordia specifications: 2,500 V for 2 x

10 μs2:DPDT

5.Rated Coil Voltage

3, 4.5, 5, 12, 24 VDC

91

2f G6K-2F中文资料

Application Examples

Telephones, communications equipment, measurement devices, office automation machines, and audio–visual products.

Specifications

Contact mechanism:Bifurcated crossbar Ag (Au-alloy contact)Enclosure ratings:Fully sealed■

Coil Ratings

Single-side Stable Models

G6K-2F, G6K-2G, G6K-2PRated voltageRated currentCoil resistanceMust operate voltageMust release voltageMax. voltagePower consumptionNote:

3 VDC33.0 mA91 ?

4.5 VDC23.2 mA194 ?

5 VDC21.1 mA237 ?

12 VDC9.1 mA1,315 ?

80% max. of rated voltage10% min. of rated voltage

150% of rated voltage at 23°C to 70°CApprox. 100 mW

1.The rated current and coil resistance are measured at a coil temperature of 23°C with a tolerance of ±10%.2.The operating characteristics are measured at a coil temperature of 23°C.

3.The maximum voltage is the highest voltage that can be imposed on the relay coil instantaneously.

Single-side Stable Models (Bellcore Version)

G6K-2F-Y, G6K-2G-Y, G6K-2P-YRated voltageRated currentCoil resistanceMust operate voltageMust release voltageMax. voltagePower consumptionNote:

3 VDC33.0 mA91 ?

4.5 VDC23.2 mA194 ?

5 VDC21.1 mA237 ?

12 VDC9.1 mA1,315 ?

24 VDC4.6 mA5,220 ?

80% max. of rated voltage10% min. of rated voltage

150% of rated voltage at 23°C to 70°CApprox. 100 mW

1.The rated current and coil resistance are measured at a coil temperature of 23°C with a tolerance of ±10%.2.The operating characteristics are measured at a coil temperature of 23°C.

3.The maximum voltage is the highest voltage that can be imposed on the relay coil instantaneously.

Single-winding Latching Models (Bellcore Version)

G6KU-2F-Y, G6KU-2G-Y, G6KU-2P-YRated voltageRated currentCoil resistanceMust set voltageMust reset voltageMax. voltagePower consumptionNote:

3 VDC33.0 mA91 ?

4.5 VDC23.2 mA194 ?

5 VDC21.1 mA237 ?

12 VDC9.1 mA1,315 ?

24 VDC4.6 mA5,220 ?

75% max. of rated voltage75% max. of rated voltage

150% of rated voltage at 23°C to 70°CApprox. 100 mW

1.The rated current and coil resistance are measured at a coil temperature of 23°C with a tolerance of ±10%.2.The operating characteristics are measured at a coil temperature of 23°C.

3.The maximum voltage is the highest voltage that can be imposed on the relay coil instantaneously.

92

2f G6K-2F中文资料

■Contact Ratings

Resistive load

0.3 A at 125 VAC; 1 A at 30 VDC

1 A

125 VAC, 60 VDC

1 ALoadRated loadRated carry currentMax. switching voltageMax. switching current

■Characteristics

ItemSingle-side stable models (double-pole)

G6K-2F, G6K-2G, G6K-2PG6K-2F-Y, G6K-2G-Y, G6K-2P-YSingle-winding latching modelG6KU-2F-Y, G6KU-2G-Y, G6KU-2P-Y

3 ms max. (approx. 1.2 ms)

3 ms max. (approx. 1.2 ms)Contact resistance (See note 1.)Operating (set) time (See note 2.)Release (reset) time (See note 2.)

Dielectric strengthCoil and contacts100 m? max.3 ms max. (approx. 1.4 ms)3 ms max. (approx. 1.3 ms)1,500 VAC, 50/60 Hz for 1 minInsulation resistance (See note 3.)1,000 M? min. (at 500 VDC)

Contacts of different 1,000 VAC, 50/60 Hz for 1 minpolarity

Contacts of same po-750 VAC, 50/60 Hz for 1 minlarity

Impulse withstand voltageCoil and contacts1,500 V (10 x 160 μs)2,500 V (2 x 10 μs), 1,500 V (10 x 160 μs)Contacts of different 1,500 V (10 x 160 μs)polarity

Contacts of same po-larity

Vibration resistanceDestruction: 10 to 55 Hz, 2.5-mm single amplitude (5-mm double amplitude) and 55 to 500 Hz,

300 m/s2 (approx. 30G)Malfunction: 10 to 55 Hz, 1.65-mm single amplitude (3.3-mm double amplitude) and 55 to 500 Hz,

200 m/s2 (approx. 20G)

Destruction: 1,000 ms2 (approx. 100G)

Malfunction: 750 ms2 (approx. 75G)

Mechanical: 50,000,000 operations min. (at 36,000 operations/hour)Electrical: 100,000 operations min. (with a rated load at 1,800 operations/hour)

10 μA at 10 mVDC

Operating: ?40°C to 70°C (with no icing or condensation)

Operating: 5% to 85%

Approx. 0.7 gShock resistanceEnduranceFailure rate (P level) (See note 4.)Ambient temperature Ambient humidityWeight

扩展:g6k 2f y / g6k 2f y 使用说明 / g6k 2f

Note:

Note:The above values are initial values.1.The contact resistance was measured with 10 mA at 1 VDC with a voltage-drop method.

2.Values in parentheses are actual values.

3.The insulation resistance was measured with a 500-VDC megohmmeter applied to the same parts as those used for checkingthe dielectric strength.

4.This value was measured at a switching frequency of 120 operations/min and the criterion of contact resistance is 50 ?. Thisvalue may vary depending on the switching frequency and operating environment. Always double-check relay suitability underactual operating conditions.93

2f G6K-2F中文资料

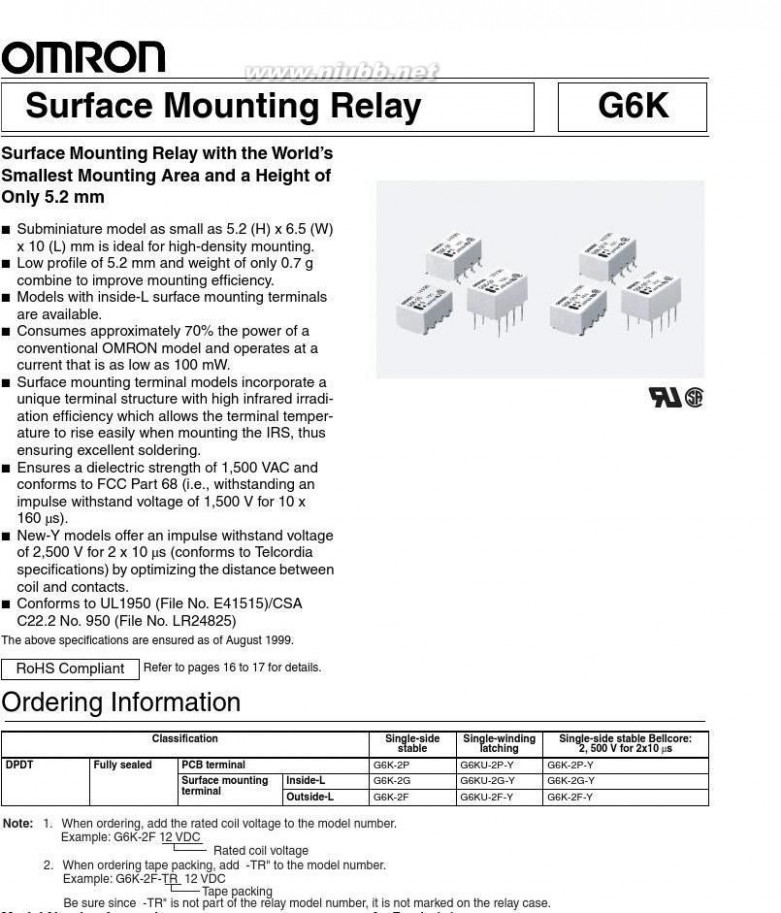

Engineering Data

Maximum Switching Power

Maximum coil voltage (%)

Switching current (A)

Ambient Temperature vs. Maximum Coil VoltageAmbient Temperature vs. Switching Current

Switching current (A)

AC resistive load

DC resistive load

Switching voltage (V)

Ambient temperature (°C)

Ambient temperature (°C)

Note: The maximum coil voltage refers to the maxi

mum value in a varying range of operating power voltage, not a continuous voltage.

Endurance

operations)Switching operations (x10 4

G6K-2G (F/P), G6K-2G (F/P)-Y

On the basis of rated voltage (%)

Ambient Temperature vs. Must

Operate or Must Release Voltage

Max. estimated value

Ambient Temperature vs. Must Set or Must Reset Voltage

G6KU-2G (F/P)-Y

On the basis of rated voltage (%)

Max. estimated value

30 VDC resistive load

Ambient temperature: 23°C Switching frequency: 1,800 operations/hour

125 VAC resistive load

Ambient temperature: 23°CSwitching frequency: 1,800 operations/hour

Must operate voltageMust release voltage

Switching current (A)

Ambient temperature (°C)Ambient temperature (°C)

Shock Malfunction

Energized

Not

energized

Electrical Endurance

(with Must Operate and Must Release Voltage) (See note.)

G6K-2G (F/P), G6K-2G (F/P)-Y

On the basis of rated voltage (%)

Sample: G6K-2G

Number of Relays: 10

Test conditions: 1 A resistive load at 30 VDC with an operation rate of 50%Switching frequency: 1,800 operations/h

Electrical Endurance

(Contact Resistance) (See note.)

G6K-2G (F/P), G6K-2G (F/P)-Y

Contact resistance (m?)

Sample: G6K-2G

Number of Relays: 10

Test conditions: 1 A resistive load

at 30 VDC with an operation rate of 50%Switching frequency: 1,800 operations/h

NO contactNC contact

Must operate

Contact resistance

Shock direction

Unit: m/s2

Sample: G6K-2G

Number of Relays: 10

Must release

Conditions: Shock is applied in ±X, ±Y, and ±Z di

rections three times each with and without energizing the Relays to check the number of contact malfunctions.

3

Operating frequency (x10 operations)

Operating frequency (x10 operations)Note: The tests were conducted at an

ambient temperature of 23?C.

3

Note: The tests were conducted at an

ambient temperature of 23?C.

94

2f G6K-2F中文资料

Note:

1.The tests were conducted at an ambient temperature of 23°C.

2.High-frequency characteristics depend on the PCB to which the Relay is mounted. Always check these characteristics includingendurance in the actual machine before use.

95

2f G6K-2F中文资料

Dimensions

Note:■

All units are in millimeters unless otherwise indicated.

DPDT

Mounting Dimensions (Top View)Tolerance: ±0.1 mm

Terminal Arrangement/Internal Connections (Top View)

G6K-2F

Note: Each value has a tolerance of ±0.3 mm.

Orientation mark

G6K-2G

Mounting Dimensions (Top View)Tolerance: ±0.1 mm

Terminal Arrangement/Internal Connections (Top View)

Note: Each value has a tolerance of ±0.3 mm.

Orientation mark

G6K-2P

Mounting Dimensions (Bottom View)Terminal Arrangement/Tolerance: ±0.1 mmInternal Connections

(Bottom View)Eight, 0.8-dia. holes

Orientation mark

Note: Each value has a tolerance of ±0.3 mm.

96

2f G6K-2F中文资料

G6K-2F-YMounting Dimensions (Top View)

Tolerance: ±0.1 mmTerminal Arrangement/Internal Connections (Top View)G6K-2G-YNote: Each value has a tolerance of ±0.3 mm.Orientation markMounting Dimensions (Top View)Tolerance: ±0.1 mmTerminal Arrangement/Internal Connections (Top View)

Orientation mark

Note: Each value has a tolerance of ±0.3 mm.

G6K-2P-YMounting Dimensions (Bottom View)Tolerance: ±0.1 mm

扩展:g6k 2f y / g6k 2f y 使用说明 / g6k 2f

Eight,

0.8-dia. holesTerminal Arrangement/Internal Connections (Bottom View)Orientation mark

Note: Each value has a tolerance of ±0.3 mm.

G6KU-2F-YMounting Dimensions (Top View)

Tolerance: ±0.1 mmTerminal Arrangement/Internal Connections (Top View)

Note: Each value has a tolerance of ±0.3 mm.Orientation mark

G6KU-2G-YMounting Dimensions (Top View)Tolerance: ±0.1 mmTerminal Arrangement/Internal Connections (Top View)G6KU-2P-YNote: Each value has a tolerance of ±0.3 mm.Mounting Dimensions (Bottom View)Terminal Arrangement/Internal Connections Tolerance: ±0.1 mmEight, 0.8-dia. holes(Bottom View)

Orientation markOrientation mark

Note: Each value has a tolerance of ±0.3 mm.

97

2f G6K-2F中文资料

Stick Packing and Tape Packing

Stick Packing

Relays in stick packing are arranged so that the orientation mark

of each Relay in on the left side. Fifty Relays are packed on one

stick.

Be sure not to make mistakes in Relay orientation when mounting

the Relay to the PCB.Stopper (gray)Orientation of Relays

Stopper (green)

Stick length: 520 mm (stopper not included)No. of Relays per stick: 50

Tape Packing (Surface Mounting Terminal

Models)

When ordering Relays in tape packing, add the prefix “-TR” to the

model number, otherwise the Relays in stick packing will be pro-vided.Tape Type:ETX7200 (EIAJ (Electronic Industrial Association of Japan))Reel type:RPM-16D (EIAJ)Relays per Reel: 900

1. Direction of Relay Insertion

Top tape (cover tape)Pulling directionOrientation mark3. Carrier Tape DimensionsG6K-2F, G6K-2F-Y, G6KU-2F-Y

Pulling direction

Carrier tapeEmboss tape

2. Reel DimensionsG6K-2G, G6K-2G-Y, G6KU-2G-Y

98

2f G6K-2F中文资料

Recommended Soldering Method

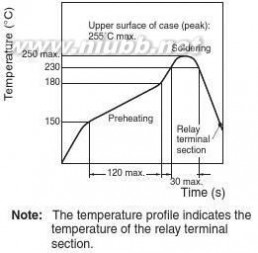

Temperature indicate the surface temperature of the PCBs.IRS Method (for surface mounting terminal models)(1) IRS Method (Mounting Solder: Lead)

(2) IRS Method (Mounting Solder: Lead-free)

Temperature (°C)

220 to245180 to200

Soldering

150

Preheating

?

?In order to perform correct soldering, it is recommended that the correct soldering conditions be maintained as shown below on the leftside.

90 to 120

20 to 30

Time (s)

Correct Soldering

RelayTerminal

SolderLand

Incorrect Soldering

Insufficient amount of solder

Excessive amount of solder

PCB

Visually check that the Relay is properly soldered.■

Approved Standards

UL approval:UL1950 (File No. E41515)

CSA approval:C22.2 No. 950 (File No. LR31928)

Contact formDPDT

Coil rating

G6K-2G(F/P): 3 to 12 VDC

G6K(U)-2G(F/P)-Y: 3 to 24 VDC

Contact rating

1 A at 30 VDC0.5 A at 60 VDC0.3 A at 125 VAC

Number of test operations6,000

99

2f G6K-2F中文资料

Precautions

Refer to page25 for information on general precautions. Be sure to read these precautions before using the Relay.

Latching Relay MountingCorrect Use

Make sure that the vibration or shock that is generated from other Long-term Continuously ON Contacts

devices, such as relays in operation, on the same panel and Using the Relay in a circuit where the Relay will be ON continu-imposed on the Latching Relay does not exceed the rated value, ously for long periods (without switching) can lead to unstable

otherwise the Latching Relay that has been set may be reset or contacts because the heat generated by the coil itself will affect

vice versa. The Latching Relay is reset before shipping. If exces-the insulation, causing a film to develop on the contact surfaces.

sive vibration or shock is imposed, however, the Latching Relay We recommend using a latching relay (magnetic-holding relay) in

may be set accidentally. Be sure to apply a reset signal before this kind of circuit. If a single-side stable model must be used in

use.this kind of circuit, we recommend using a fail-safe circuit design

Maximum Allowable Voltagethat provides protection against contact failure or coil burnout.

The maximum allowable voltage of the coil can be obtained from Relay Handling

the coil temperature increase and the heat-resisting temperature Use the Relay as soon as possible after opening the moisture-of coil insulating sheath material. (Exceeding the heat-resisting proof package. If the Relay is left for a long time after opening the

temperature may result in burning or short-circuiting.) The maxi-moisture-proof package, the appearance may suffer and seal fail-mum allowable voltage also involves important restrictions which ure may occur after the solder mounting process. To store the

扩展:g6k 2f y / g6k 2f y 使用说明 / g6k 2f

include the following:Relay after opening the moisture-proof package, place it into the

?Must not cause thermal changes in or deterioration of the insu-original package and sealed the package with adhesive tape.

lating material.

When washing the product after soldering the Relay to a PCB,

?Must not cause damage to other control devices.use a water-based solvent or alcohol-based solvent, and keep the

?Must not cause any harmful effect on people.solvent temperature to less than 40°C. Do not put the Relay in a

?Must not cause fire.cold cleaning bath immediately after soldering.

Therefore, be sure to use the maximum allowable voltage beyond Soldering

the value specified in the catalog.Soldering temperature: Approx. 250°C (260°C if the DWS method

As a rule, the rated voltage must be applied to the coil. A voltage is used)

exceeding the rated value, however, can be applied to the coil Soldering time: Approx. 5 s max. (approx. 2 s for the first time and

provided that the voltage is less than the maximum allowable volt-approx. 3 s for the second time if the DWS method is used)

age. It must be noted that continuous voltage application to the

Be sure to adjust the level of the molten solder so that the solder

coil will cause a coil temperature increase thus affecting charac-will not overflow onto the PCB.

teristics such as electrical life and resulting in the deterioration of

Claw Securing Force During Automatic Mountingcoil insulation.During automatic insertion of Relays, make sure to set the secur-Coating

ing force of each claw to the following so that the Relays charac-The Relay mounted on the PCB may be coated or washed but do

teristics will be maintained.

not apply silicone coating or detergent containing silicone, other-wise the silicone coating or detergent may remain on the surface of the Relay.PCB Mounting

If two or more Relays are closely mounted with the long sides of the Relays facing each other and soldering is performed with infrared radiation, the solder may not be properly exposed to the

Direction A: 1.96 Ninfrared rays. Be sure to keep the proper distance between adja-Direction B: 4.90 N

cent Relays as shown below.Direction C: 1.96 N

Environmental Conditions During Operation, Storage, and

Transportation

Protect the Relay from direct sunlight and keep the Relay under normal temperature, humidity, and pressure.

If the Relay is stored for a long time in an adverse environment with high temperature, high humidity, organic gases, or sulfide gases, sulfide or oxide films will form on the contact surfaces. These films may result in unstable contact, contact problems, or functional problems. Therefore, operate, store, or transport the product under specified environmental conditions.

G6K-2G

2 mm min.

G6K-2F

2.7 mm min.

Two or more Relays may be closely mounted with the short sides of the Relays facing each other.

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. K106-E1-04

100

扩展:g6k 2f y / g6k 2f y 使用说明 / g6k 2f

三 : S9012中文资料

元器件交易网www.cecb2b.com

s9012 S9012中文资料

元器件交易网www.cecb2b.com

扩展:s9012三极管中文资料 / s9012 pdf 中文资料 / 9012中文资料

四 : K2717中文资料

元器件交易网www.cecb2b.com

k2717 K2717中文资料

元器件交易网www.cecb2b.com

k2717 K2717中文资料

元器件交易网www.cecb2b.com

k2717 K2717中文资料

元器件交易网www.cecb2b.com

k2717 K2717中文资料

元器件交易网www.cecb2b.com

扩展:k2717 / k2717参数 / k2717引脚图

本文标题:中文资料-1N5300-1中文资料61阅读| 精彩专题| 最新文章| 热门文章| 苏ICP备13036349号-1