一 : epoxy adhesive

journalofmaterialsprocessingtechnology205(2008)

article

Articlehistory:

infoabstract

Theobjectiveofthisstudywastodevelopinformationonthein?uenceofadhesivethicknessandaluminum?llercontentonthemechanicalperformanceofaluminumjointsbondedbyaluminumpowder?lledepoxy.Theadhesivestrengthofthejointswasdeterminedbyuti-lizingthesingle-lapsheartest.Thein?uenceofadhesivethicknessandaluminum?llercontentonstressdistributionwithintheadhesivewasalsoanalyzedby?niteelementmethod(FEM).BothFEManalysisandtheexperimentalinvestigationshowthatingen-eraladhesionstrengthdecreasesasthethicknessoftheadhesiveincreases.Itisobserved

Received21May2007Receivedinrevisedform26October2007

Accepted14November2007

Keywords:AdhesiveEpoxyMetal?llerAluminumJointsThickness

fromthepredictions(FEMsimulations)thatthestresslevelincreasesattheadhesive–metalsubstrateinterfaceasthealuminum?llercontentintheadhesiveincreases.Experimentalresultsshowthatepoxyadhesiveretainsitsstrengthuptothe50wt%aluminum?llercon-tent.Thejointsfailincohesivemode(failurewithintheadhesive)duetothehighstresslevelsgeneratedintheadhesive,whichindicatesthattheadhesiontothemetalsurfaceisstrongerthanthatoftheinteriorpartoftheadhesive.

?2007ElsevierB.V.Allrightsreserved.

1.Introduction

Epoxiesarewidelyusedashigh-performancestructuraladhe-sives,especiallyinautomotiveandaircraftmanufacture.Epoxyresinsareattractiveformetal-bondingadhesivesys-temsbecauseoftheirabilitytocurewithoutproducingvolatileby-productsandtheirlowshrinkageuponcuring(lessthan0.5%)(TaiandSzklarska-Smialowska,1993).Epoxiesareabletobondwelltoavarietyoftreatedoruntreatedmetalsurfaces(Mohan,1990).Inaircraftmanufacture,thereisagreatneedforevenlystressed,smoothbondingofthinaluminumsheetandhoneycombmaterials.Epoxyadhesiveshaveagoodaf?n-ityforaluminumalloysurfaces,andtheoxidelayersproducedduringsurfacepreparation(Chasseretal.,1993).

Tobeabletoobtainastrongandstablebondbetweenthemetalandtheadhesive,thenaturalsurfaceoxideshouldberemovedandreplacedwithanew,continuous,solid,corrosionresistantoxidelayer.Theremovalcanbedonemechani-callyand/orchemically.Mechanical(abrasive)cleaningalsoincreasesthesurfaceroughnessand,consequently,thebondstrengthbymechanicalinterlockingandbytheincreasednumberofchemicalbondsonthelargersurfacearea.Vari-ouschemicaltreatments,themostcommonbeingacidetches,havebeendevelopedtomodifytheoxide,torenderitmorereceptivetobonding(KozmaandOlefjord,1987a,b;Brewis,1985;HoggandJanardhana,1993;Kinloch,1983).

However,ofteninindustrialpractice,althoughthebene-?tsofsurfacepreparationarewidelyknown,itisnotdone

Correspondingauthor.Fax:+9744852491

E-mailaddress:ramazank@qu.edu.qa(R.Kahraman).

0924-0136/$–seefrontmatter?2007ElsevierB.V.Allrightsreserved.doi:10.1016/j.jmatprotec.2007.11.121

?

adhesive epoxy adhesive

184

journalofmaterialsprocessingtechnology205(2008)183–189

properlyforeconomicandsafetyreasons.Propersurfacepreparationtakesextraproductiontime,tendstobelaborintensiveandusuallyinvolvesuseofhazardousmaterials.Hence,anindustrialstructuraladhesivemustbesuitableforuseonlessthanidealsurfaces.

Inavarietyofindustrialapplicationsepoxyadhesivesarerequiredtohaveanenhancedthermalconductivity.Thenor-malmethodforchangingthisphysicalpropertyistoaddtotheepoxya?llerofhigherconductivitythanthecontinuousphase(TaiandSzklarska-Smialowska,1993;HermansenandTunick,1989;TomlinsonandStapley,1977;LeeandNeville,1967;Kingery,1960;NieberleinandSteverding,1977;Gaynesetal.,1997;Hahnetal.,1998;Subramanianetal.,1998;Nikkeshietal.,1998).Bytheincorporationof?llersintotheadhesive,theresincontent(andthusthecost)isalsoreduced.

Achievingimprovedthermalconductivityisdependenton?llerselectionandloadinglevel.Fillertype,size,shapeandvolumefractiondeterminetheadhesivethermalcon-ductance.Theadhesivethermalconductivityincreaseswithincreasingvolumefractionofthe?ller.Theoretically,thethermalconductivityofthe?llerisnotanimportantvari-ableexceptwhenitiswithinafactorof10ofthethermalconductivityofthepolymericmatrix(adhesive).Mostmetal?llershavethermalconductivitiesgreaterthan10timesthematrixthermalconductivity(HermansenandTunick,1989).

Aluminapowderisoneofthecommonlyused?llersforimprovingthethermalconductivityofadhesives,inpartic-ularinsulationadhesives.Aluminumandsilverpowdersor?akesareusedtoimprovethethermalandelectricalconduc-tivitiesforadhesivesintendedtobeanelectricalorthermalpath(HermansenandTunick,1989;KangandPurushothaman,1998;Luetal.,1999).The?llerlevelmustbesuf?cientlyhightoachievepoint-to-pointcontactbeforeelectricalconductiv-ityisattained(HermansenandTunick,1989).However,toohigh?llercontentmightcauseadegradationinmechani-calpropertiesoftheadhesive(Nikkeshietal.,1998).Therearealsoseveralcommerciallyavailableepoxyadhesivesrein-forcedwithothermetal?llerssuchasaluminumpowder.

Whiletheimprovementonthermalpropertiesofadhesivesbyadditionofmetal?llersisobvious(HermansenandTunick,1989;TomlinsonandStapley,1977;LeeandNeville,1967;Kingery,1960;NieberleinandSteverding,1977),theirin?uenceonthemechanicalpropertiesoftheadhesivejointsarenotclear.Theresultsofthisstudyareexpectedtoshedlightonthisaspect.Theobjectivewastoinvestigatethein?uenceofthe?llercontentandtheadhesivethicknessonthemechan-icalperformanceofaluminumsingle-lapjointsbondedwithaluminumpowder?lledepoxyadhesive.

61阅读提醒您本文地址:

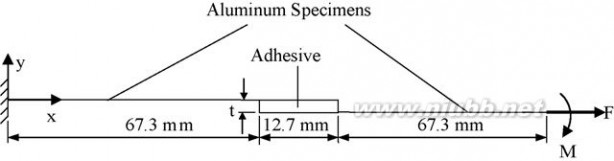

Thetraditionalevaluationofadhesivejointsbystrengthmeasurementswasutilizedinthestudy.Theadhesivestrengthwasdeterminedbyutilizingthesingle-lapsheartest(Mohan,1990;Arnold,1989;TsaiandMorton,1994;AnnualBookofASTMStandards,1992).Thesingle-lapjointcon?g-uration(Fig.1)iswidelyusedintheaerospace,automotiveandwoodandplasticindustries(HermansenandTunick,1989;Arnold,1989;Stringer,1985;DeWildeetal.,1995;JialanellaandShaffer,1993).Single-lapspecimensareeconomical,practicalandeasytomake.Theyalsoalloweasycontrol(andmeasure-ment)ofthebond

thickness.

Fig.1–Single-lapshearjointcon?guration.

Thevariationofadhesionstrengthwithadhesivethick-nessisexaminedinthispaper.Theeffectofbondthicknessonadhesiveperformanceforvariousotherjointshasbeenreportedbyfewinvestigators(Stringer,1985;Foulkesetal.,1970;Hylands,1984;Beevers,1986).However,thereisalackofstudyonthevariationofadhesioncharacteristicswithadhe-sivethicknessforsingle-lapshearjoints.Consequently,inthepresentstudy,theeffectsofmetal?lleradditionandtheadhe-sivethicknessonstressdistributionwithintheadhesivejointsareanalyzedbythe?niteelementmethod.Theexperimentsarealsocarriedouttovalidateandcomparethetheoreticalpredictionsoftheadhesionstrengthofadhesivebondsatdif-ferentthicknesses.

2.

Experimental

2.1.

Materials

Theepoxyadhesiveusedinthisinvestigationisageneral-purpose,two-partepoxy(Fusor309)obtainedfromLordCorporation.Theadhesiveispreparedbymixingequalvol-umesoftheresinandhardenerparts.Themixedadhesivecuresfullyin24–48hatroomtemperaturewithhandlingstrengthinabout8h.

Thealuminumpowderusedfor?llingtheepoxyadhesivewasobtainedfromAlliedBritanniaLimited.Thealuminumparticles(?ller)werespherical/roundishwithsizesmallerthan50?mindiameter.

Thealuminumsheetsusedasadherentsinmakingalu-minumjointswerecutfromlocallyobtainedaluminumplates.

2.2.Adhesivejointpreparation

Thefollowingprocedureswereusedforcleaningthealu-minumsheets(80mm×25.4mm)beforeadhesivelyjoiningthem(KozmaandOlefjord,1987a;Prakashetal.,1987;Semerdjiev,1970).

1.Degreasebydippingshortlyintrichloroethyleneandiso-propylalcohol,separately.2.Washwithwater.

3.Roughensurfacesbyabradercleaning(mechanicalclean-ing)by400gritsiliconcarbidegrindingpaper.

4.Degreasebydippingintrichloroethyleneandisopropylalcohol(30mineach).

adhesive epoxy adhesive

journalofmaterialsprocessingtechnology205(2008)183–189

185

Fig.2–Finiteelementmodelofthesystem.

5.Immersefor2–4hinasolutionofH2SO4,sodiumdichro-mateanddistilledwaterinproportion:22.5,7.5and70byweight,respectively(chromic–sulphuricetchingprocess).6.Washwithdistilledwater.

7.Drywithcleanpaperortissueandkeepinadesiccatoruntiluse.Thesingle-lapshearadhesivejointswerethenpreparedbybondingsurfacecleaned/treatedaluminumsheetstogetherwithneatepoxyadhesiveandthenafteradditionofaluminumpowderatseveralfractions(10,25and50wt%).Equalvolumesoftheepoxyresinandthehardenerweremixedandthenalu-minumpowderwasaddedintotheadhesivemixingagain.Adesigned?xturewasusedtoassembletheadhesivejoints.Ithadtwo?xedendplatesandamovableonebetweenthem.Themetalsheetswerebondedtogetherbetweenthemovableplateandthefarendplate.The?xtureincludedamicrometerusedforcontrollingtheadhesivethickness.Theactualadhe-sivethicknessofthecuredjointwasmeasuredbyaDigimaticCaliper.

2.3.Mechanicalcharacterizationoftheadhesivejoints

Theadhesivejointswereassembledandtestedasspeci?edinASTMD1002(AnnualBookofASTMStandards,1992).Thejointcon?gurationisshowninFig.1whiletheappliedloadsareshowninFig.2.Endtabsofthesamethicknessandmate-rialoftheadherendswereusedtoplacetheloadaxisinthesameplaneoftheoverlaparea.TheequipmentusedformechanicalcharacterizationwasanInstron5567mechani-caltestingsystem.Jointstrengths,reportedinunitsofshearstress,werecalculatedasfollows:jointstrength=

failureloadadhesivelaparea

(1)

3.Stressanalysisby?niteelementmethod

Thein?uenceofmetal?llercontentandtheadhesivethick-nessonstressdistributionwithintheadhesivejointswasanalyzedby?niteelementmethod(FEM).Dueitsversatilityandcomputationalpower,theFEMiscommonlyusedintheanalysisofmodernengineeringandscienti?csystems.Inthisstudy,theFEMisusedtomodelandanalyzetheadhesivejointthroughthewell-known?niteelementpackageANSYS.Thesystemconsistingofthejointandtwo-bondedaluminumspecimensissubjectedtotension.TheresultingshearandvonMisesstressesarecomputedforvariousadhesivecompo-sitionsandthicknessestoseetheireffectsonthemechanicalstrengthofthejoint.Thesestressesarechosen,becauseit

is

Fig.3–Theelasticbeamelement.

expectedthattheshearstressisthemodeoffailurefortheadhesivejointandthevonMisesstressisameasureonthestateofequivalentstress.

61阅读提醒您本文地址:

The?niteelementmodelofthesystemisshowninFig.2.Thetwoaluminumspecimensseeninthe?gurearemodeledusingtheBEAM3elementinANSYS(ANSYS,2005).DepictedinFig.3,thiselasticbeamelementallowsin-planehorizontalandverticaldisplacements(uandv)androtationabouttheout-of-planeaxis(?)atthetwoendnodesof1and2.AsshowninFig.3,thegrippedportionoftheleftspecimenis?xedandtherightspecimenispulledwithaforce(F)of100Nresemblingtheactualtestingconditions.Intheactualtest,thisforceisalignedwiththecentralaxisofthejointandhenceabendingmomentofM=Ft/2isappliedtoaccountfortheeccentricityoftheforceatthe?niteelementmodel(wheretistheadhesivethickness).

Thetwodimensional(2D)quadrilateralelementwithmid-sidenodesandthicknessoption,PLANE82,wasusedformodelingtheadhesivebondgivingin-planedisplacementsattheeightnodes.Thiselementisahigherversionofthefour-nodedelementinANSYSandisbettersuitedfortheapplicationswherethebendingmomentexists(ANSYS,2005).Theadhesivebondismadeofepoxyandaluminum?llerwhoseweightpercentagesarechangedtogetherwiththebondthickness(t)toobservetheireffectsonthemechanicalstrengthofthejoint.ThematerialpropertiesforthealuminumandepoxyarelistedinTable1.Themodulusofelasticity(E)andPoisson’sratio(??)fortheadhesiveareassumedasE=caEa+ceEe(2)??=ca??a+ce??e

(3)

whereEaandEearethemoduliofelasticity,and??aand??earethePoisson’sratiosforthealuminumandepoxy,respectively.Thecoef?cientscaandceintheaboveequationsdenotethefractionscorrespondingtothealuminum?llerandepoxy.

Table1–Materialproperties

Aluminum

Epoxy

Modulusofelasticity(E,GPa)68.951.0858Poisson’sratio(?)

0.333

0.38

adhesive epoxy adhesive

186

journalofmaterialsprocessingtechnology205(2008)

183–189

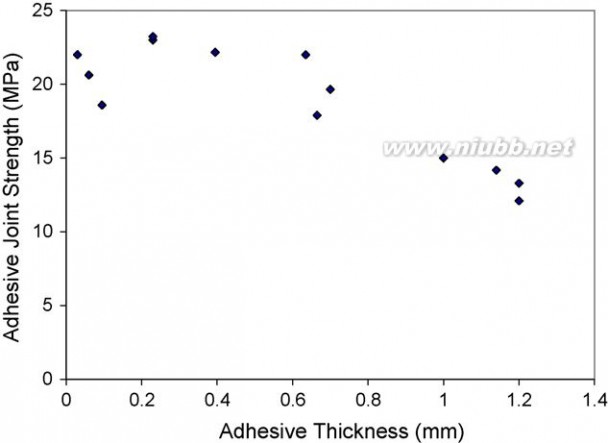

Fig.4–Aplotofadhesivejointstrengthvs.adhesivethicknessforaluminumjointsbondedwithneatepoxywithno?ller.

4.

Resultsanddiscussion

4.1.

Mechanicalcharacterization

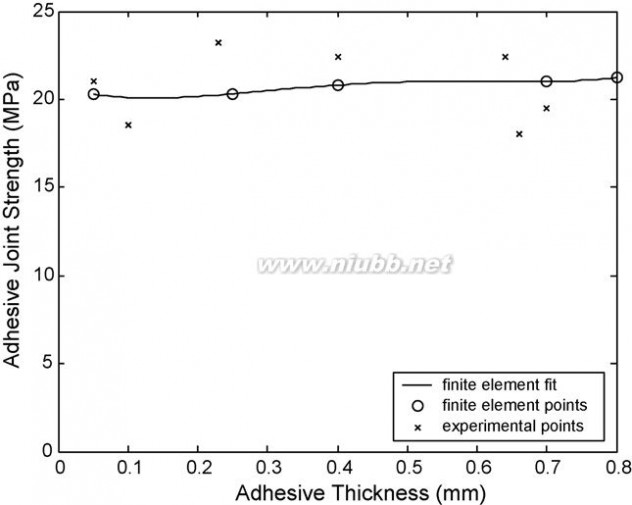

AdhesivejointstrengthversusadhesivethicknessisplottedinFig.4foraluminumjointsbondedwithneatepoxywithno?llercontent.Adhesivethicknessesinvestigatedrangedfrom0.03mmto1.3mm.Asseenintheplotthereisageneraltrendofdecreaseinsingle-lapadhesivejointshearstrengthwithadhesivethickness.Increaseofadhesivethicknessfrom0.03mmto1.3mmresultedadecreaseofabout35–40%inadhesivejointshearstrength.Howevertheeffectwasnotsig-ni?cantforadhesivethicknessesuptoabout0.7mm.

Inlightoftheaboveresult,thesmallestadhesivethickness(0.03–0.05mm)wasusedfortheexperimentsoftherestoftheinvestigation.

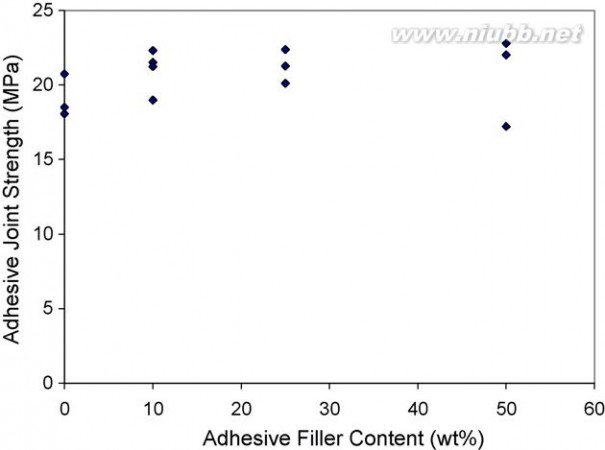

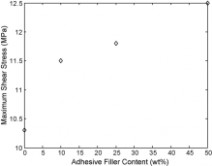

Aplotofadhesivejointstrengthversusamountofalu-minumpowderusedintheadhesiveispresentedinFig.5.Additionofaluminumparticlesasmuchas50wt%didnotcauseasigni?cantdecreaseinadhesivejointstrength.

It

Fig.5–Aplotofadhesivejointstrengthvs.adhesive?ller

content.

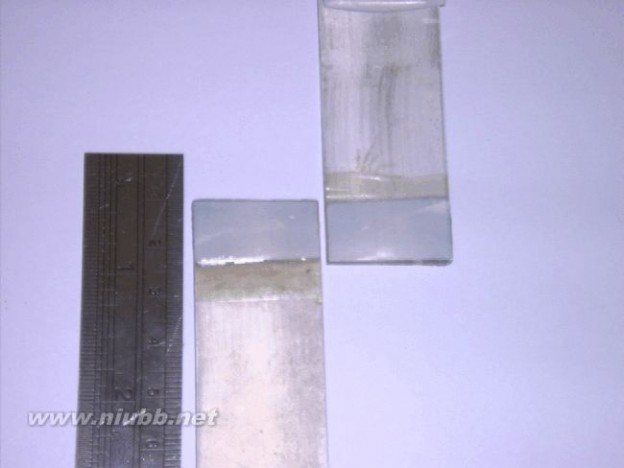

Fig.6–Fracturesurfacesofanaluminumjointbondedbyepoxywithnometal

?ller.

Fig.7–Fracturesurfacesofanaluminumjointbondedbyepoxywith25wt%aluminum?ller.

shouldbenotedthat50wt%Al?llercontentintheadhesivecorrespondstoabout44.45%involumebecauseofdensitydifferencebetweenaluminumparticlesandepoxyadhesive.

Fracturedspecimenswerevisuallyexaminedtodeterminethefailuremode.Thejointsfailedalmostcompletelyincohe-sivefailuremode.Cohesivefailureoccurswhentheadhesiveseparatesfromitself(failurewithinadhesive).AdhesivelayersleftonbothjointsurfacesareclearlyshowninFigs.6and7forneatepoxyandepoxywith25wt%aluminum?llercontent,asexamples.

4.2.FEManalysis

TheshearandvonMisesstressesforvariousbondthick-nessesandvariousadhesivecompositionswereanalyzed.Accordingtothestresscontourswhicharenotshownhere,themaximumshearandvonMisesstressesoccurattheadhesive–metalsubstrateinterface.Thisisespeciallytruefortheshearstresses,whichalmostvanishtowardthemiddleoftheadhesive.ThesametrendalsoexistsforthevonMises

adhesive epoxy adhesive

journalofmaterialsprocessingtechnology205(2008)183–189

187

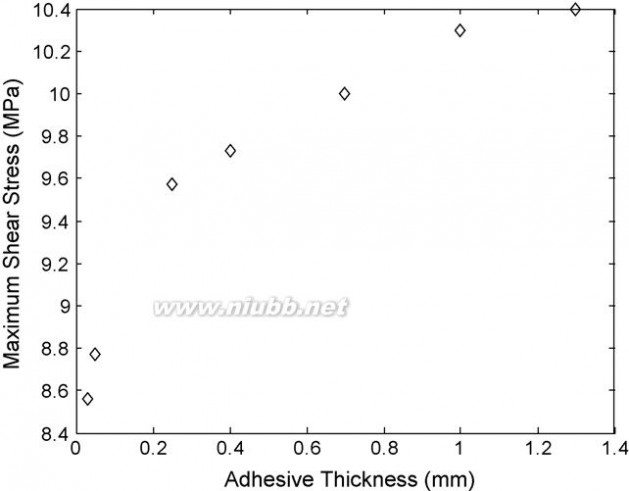

Fig.8–Maximumshearstressvs.adhesivethicknessforneatepoxy.

stresses,whichattainmaximumattheedgesanddecreaseawayfromtheedges.

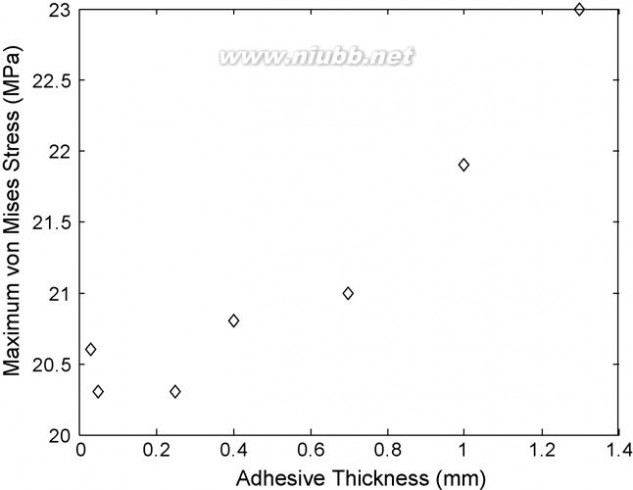

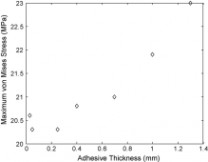

Inordertoinvestigatetheeffectofbondthicknessonthebondstrength,themaximumshearandvonMisesstressesareplottedagainstthebondthicknessforneatepoxyadhesiveinFigs.8and9.Asseeninthese?guresshearstressesintheadhesiveincrease(decreasingthebondstrength)asthebondthicknessincreases.AsforthemaximumvonMisesstresses,theyshowslightlydifferentormixedbehavior(Fig.9),butthegeneraltrendissimilartothetrendfortheshearstresses.Inotherwords,thevonMisesstressesarealsoincreasedasthethicknessofthebondisincreased.ItshouldbenotedthattheshearstresscontributiontothevonMisesstressissigni?cantinthebondregionclosetothealuminumplate.This,inturn,resultsinpossiblefailureofbondinginthisregion.

61阅读提醒您本文地址:

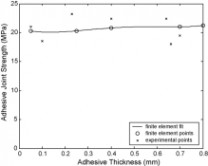

Fig.10showstheplotsof?niteelementpredictionsandexperimentalresultsfortheadhesivejointstrengthofneatepoxyatdifferentadhesivethicknesses.Itcan

be

Fig.9–MaximumvonMisesstressvs.adhesivethicknessforneat

epoxy.

Fig.10–Adhesivejointstrengthvs.adhesivethicknessforneat

epoxy.

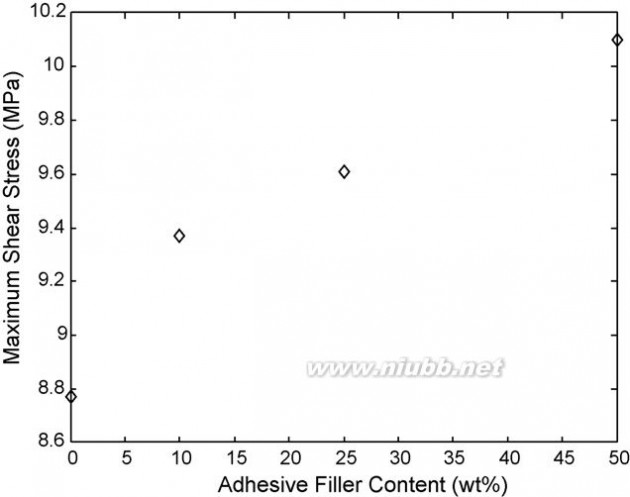

Fig.11–Variationofmaximumshearstresswith

aluminumcontentforadhesivethicknessof0.05mm.

observedthatthe?niteelementpredictionsagreewellwiththeexperimentalresults.Somediscrepanciesbetweenbothresultsarebecauseof(i)theexperimentalerror,whichisestimatedas7%(basedontheexperimentalrepeats)and(ii)theassumptionofthehomogeneousadhesiveprop-ertiesacrossthebondingsectioninthe?niteelementsimulations.

Stressanalysiswasalsodoneforvariousadhesivecompo-sitions.Themassaverageofmechanicalpropertieswasusedinsimulationstoaccountforthealuminumpowderconcen-trationintheadhesivecomposition.Figs.11and12showtheplotsofthemaximumshearandvonMisesstressesversusadhesivecompositionsforthebondthicknessof0.05mm.Itisevidentthatthesestressesgethigherastheweightpercent-ageofaluminumcontentintheadhesivebondincreases.Inotherwords,thealuminumcontentintheadhesiveadverselyaffectstheadhesionstrengthofthejoint.However,asthebondthicknessincreasesthiseffectdiminishesandtherateofincreaseinstressestendstodecreaseathighbondthick-

adhesive epoxy adhesive

188

journalofmaterialsprocessingtechnology205(2008)

references

AnnualBookofASTMStandards,1992.AmericanSocietyfor

TestingandMaterials,vol.15.06.ASTM,Philadelphia,PA,pp.47-50.

ANSYS,2005.Release10.0,ANSYS,Inc.,Canonsburg,

Pennsylvania,USA.

Arnold,J.R.,July1989.Adhesivelybondedcoatedsteels.Automot.

Eng.,39–44.

Beevers,A.,1986.Coaxialjointsinengineeringassembly.Mater.

Sci.Technol.2,97–102.

adhesive epoxy adhesive

journalofmaterialsprocessingtechnology205(2008)183–189

189

Brewis,D.M.,1985.Factorsaffectingbondingofmetals.In:

ContinuousCasting’85,ProceedingsoftheInternationalConferenceSponsoredandOrganizedbyTheInstituteofMetals,London,pp.629–644.

Chasser,A.M.,Makhlouf,J.M.,Schneider,J.R.,March1993.

Rubber-basedstructuraladhesiveisanewoptionformetalbonding.Adhes.Age,36–39.

DeWilde,W.P.,VanVinckenroy,G.,Tirry,L.,Cardon,A.H.,1995.

Effectsoftheenvironmentandcuringonthestrengthofadhesivejoints.J.Adhes.Sci.Technol.9,149–158.

Foulkes,H.,Shields,J.,Wake,W.C.,1970.Thevariationofbond

strengthwithtemperature:apreliminarystudyofmetal-to-metaladhesion.J.Adhes.2,254–269.

Gaynes,M.A.,Matienzo,L.J.,Zimmerman,J.A.,Vanchart,D.,1997.

Analysisandcharacterizationofelectricallyconductiveadhesives.In:ElectronicPackagingMaterialsScience.IX.MaterialsResearchSocietySymposiumProceedings,Warrendale,PA,USA,pp.139–151.

Hahn,O.,Meschut,G.,Koyro,M.,1998.Thermalconductivity,

strengthandageingbehaviourofadhesive-bondedjointswith?ller-modi?edadhesives.SchweissenundSchneiden/Weld.Cutting50(7),E130–E133.

Hermansen,R.D.,Tunick,S.A.,October1989.Formulating

custom-tailoredthermaltransferadhesives.Adhes.Age,38–41.

Hogg,I.C.,Janardhana,M.N.,1993.Surfacepreparationof

adhesivelybondedjoints.In:Chandra,T.,Dhingra,A.K.(Eds.),AdvancedComposites’93,InternationalConferenceonAdvancedCompositeMaterials.TheMinerals,Metals&MaterialsSociety,pp.455–461.

Hylands,R.W.,1984.Strengthcharacteristicsofmonoand

multiple-wiresteeltosteeljointsbondedwithanepoxyadhesive.In:Mittal,K.L.(Ed.),AdhesiveJoints:Formation,Characteristics,andTesting.PlenumPress,NewYork,pp.165–193.

Jialanella,G.L.,ShafferII,E.O.,1993.Theeffectofadhesive

modulusontheperformanceofSMClapshearjoints.J.Adhes.Sci.Technol.7,1171–1181.

Kang,S.,Purushothaman,S.,1998.Developmentoflowcost,low

temperatureconductiveadhesives.In:ProceedingsoftheElectronicComponentsandTechnologyConference,IEEE,Piscataway,NJ,USA,pp.1031–1035.Kingery,W.D.,1960.IntroductiontoCeramics.JohnWiley&Sons,

Inc.,NewYork.

Kinloch,A.J.,1983.DurabilityofStructuralAdhesives.Applied

SciencePublishers,London.

Kozma,L.,Olefjord,I.,1987a.Basicprocessesofsurface

preparationandbondformationofadhesivelyjoinedaluminum.Mater.Sci.Technol.3,860–874.

Kozma,L.,Olefjord,I.,1987b.Surfacetreatmentofsteelfor

structuraladhesivebonding.Mater.Sci.Technol.3,954–962.Lee,H.,Neville,K.,1967.HandbookofEpoxyResins.McGraw-Hill,

NewYork.

Lu,D.,Tong,Q.K.,Wong,C.P.,1999.Conductivitymechanismsof

isotropicconductiveadhesives(ICA’s).IEEETrans.Electron.Pack.Manuf.22(3),223–227.

Mohan,R.,February1990.Analyzingadhesivelybondedjointsfor

61阅读提醒您本文地址:

automotiveapplications.Plast.Eng.,47–51.

Nieberlein,V.A.,Steverding,B.,1977.Thermalconductivityof

epoxy–aluminumpowdermixtures.J.Mater.Sci.Lett.12,1685–1688.

Nikkeshi,S.,Kudo,M.,Masuko,T.,1998.Dynamicviscoelastic

propertiesandthermalpropertiesofNipowder–epoxyresincomposites.J.Appl.Polym.Sci.69(13),2593–2598.

Prakash,R.,Srivastava,V.K.,Gupta,G.S.R.,December1987.

Behaviorofadhesivejointsincorrosiveenvironment.Exp.Mech.,346–351.

Semerdjiev,S.,1970.Metal-to-MetalAdhesiveBonding.Business

BooksLimited,London.

Stringer,L.G.,1985.Comparisonoftheshearstress–strain

behaviourofsomestructuraladhesives.J.Adhes.18,185–196.Subramanian,S.,Kustas,F.,Rawal,S.,Shinn,E.T.,1998.

Fabrication,testingandanalysisofcarbon-carbon/aluminumbondedjointswithhighthermalconductivity.In:CollectionofTechnicalPapers—AIAA/ASME/ASCE/AHS/ASCStructures,StructuralDynamics&MaterialsConference,vol.3,AIAA,Reston,VA,USA,pp.2423–2433.

Tai,R.C.L.,Szklarska-Smialowska,Z.,1993.Absorptionofwater

bydifferent?llers-incorporatedautomotiveepoxyadhesives.J.Mater.Sci.28,6199–6204.

Tomlinson,W.J.,Stapley,D.,1977.Thermalconductivityofepoxy

resin–aluminum(0–50%)composites.J.Mater.Sci.Lett.12,1689–1690.

Tsai,M.-Y.,Morton,J.,1994.Anoteonpeelstressesinsingle-lap

adhesivejoints.J.Appl.Mech.61,712–715.

61阅读提醒您本文地址:

二 : epoxy adhesive

journalofmaterialsprocessingtechnology205(2008)

183–189

journalhomepage:www.61k.comlocate/jmatprote

c

In?uenceofadhesivethicknessand?llercontentonthemechanicalperformanceofaluminumsingle-lapjointsbondedwithaluminumpowder?lledepoxyadhesive

RamazanKahramana,?,MehmetSunarb,BekirYilbasb

ab

ChemicalEngineeringDepartment,QatarUniversity,DohaQatar

DepartmentofMechanicalEngineering,KingFahdUniversityofPetroleum&Minerals,Dhahran31261,SaudiArabia

article

Articlehistory:

infoabstract

Theobjectiveofthisstudywastodevelopinformationonthein?uenceofadhesivethicknessandaluminum?llercontentonthemechanicalperformanceofaluminumjointsbondedbyaluminumpowder?lledepoxy.Theadhesivestrengthofthejointswasdeterminedbyuti-lizingthesingle-lapsheartest.Thein?uenceofadhesivethicknessandaluminum?llercontentonstressdistributionwithintheadhesivewasalsoanalyzedby?niteelementmethod(FEM).BothFEManalysisandtheexperimentalinvestigationshowthatingen-eraladhesionstrengthdecreasesasthethicknessoftheadhesiveincreases.Itisobserved

Received21May2007Receivedinrevisedform26October2007

Accepted14November2007

Keywords:AdhesiveEpoxyMetal?llerAluminumJointsThickness

fromthepredictions(FEMsimulations)thatthestresslevelincreasesattheadhesive–metalsubstrateinterfaceasthealuminum?llercontentintheadhesiveincreases.Experimentalresultsshowthatepoxyadhesiveretainsitsstrengthuptothe50wt%aluminum?llercon-tent.Thejointsfailincohesivemode(failurewithintheadhesive)duetothehighstresslevelsgeneratedintheadhesive,whichindicatesthattheadhesiontothemetalsurfaceisstrongerthanthatoftheinteriorpartoftheadhesive.

?2007ElsevierB.V.Allrightsreserved.

1.Introduction

Epoxiesarewidelyusedashigh-performancestructuraladhe-sives,especiallyinautomotiveandaircraftmanufacture.Epoxyresinsareattractiveformetal-bondingadhesivesys-temsbecauseoftheirabilitytocurewithoutproducingvolatileby-productsandtheirlowshrinkageuponcuring(lessthan0.5%)(TaiandSzklarska-Smialowska,1993).Epoxiesareabletobondwelltoavarietyoftreatedoruntreatedmetalsurfaces(Mohan,1990).Inaircraftmanufacture,thereisagreatneedforevenlystressed,smoothbondingofthinaluminumsheetandhoneycombmaterials.Epoxyadhesiveshaveagoodaf?n-ityforaluminumalloysurfaces,andtheoxidelayersproducedduringsurfacepreparation(Chasseretal.,1993).

Tobeabletoobtainastrongandstablebondbetweenthemetalandtheadhesive,thenaturalsurfaceoxideshouldberemovedandreplacedwithanew,continuous,solid,corrosionresistantoxidelayer.Theremovalcanbedonemechani-callyand/orchemically.Mechanical(abrasive)cleaningalsoincreasesthesurfaceroughnessand,consequently,thebondstrengthbymechanicalinterlockingandbytheincreasednumberofchemicalbondsonthelargersurfacearea.Vari-ouschemicaltreatments,themostcommonbeingacidetches,havebeendevelopedtomodifytheoxide,torenderitmorereceptivetobonding(KozmaandOlefjord,1987a,b;Brewis,1985;HoggandJanardhana,1993;Kinloch,1983).

However,ofteninindustrialpractice,althoughthebene-?tsofsurfacepreparationarewidelyknown,itisnotdone

Correspondingauthor.Fax:+9744852491

E-mailaddress:ramazank@qu.edu.qa(R.Kahraman).

0924-0136/$–seefrontmatter?2007ElsevierB.V.Allrightsreserved.doi:10.1016/j.jmatprotec.2007.11.121

?

184

journalofmaterialsprocessingtechnology205(2008)183–189

properlyforeconomicandsafetyreasons.Propersurfacepreparationtakesextraproductiontime,tendstobelaborintensiveandusuallyinvolvesuseofhazardousmaterials.Hence,anindustrialstructuraladhesivemustbesuitableforuseonlessthanidealsurfaces.

Inavarietyofindustrialapplicationsepoxyadhesivesarerequiredtohaveanenhancedthermalconductivity.Thenor-malmethodforchangingthisphysicalpropertyistoaddtotheepoxya?llerofhigherconductivitythanthecontinuousphase(TaiandSzklarska-Smialowska,1993;HermansenandTunick,1989;TomlinsonandStapley,1977;LeeandNeville,1967;Kingery,1960;NieberleinandSteverding,1977;Gaynesetal.,1997;Hahnetal.,1998;Subramanianetal.,1998;Nikkeshietal.,1998).Bytheincorporationof?llersintotheadhesive,theresincontent(andthusthecost)isalsoreduced.

Achievingimprovedthermalconductivityisdependenton?llerselectionandloadinglevel.Fillertype,size,shapeandvolumefractiondeterminetheadhesivethermalcon-ductance.Theadhesivethermalconductivityincreaseswithincreasingvolumefractionofthe?ller.Theoretically,thethermalconductivityofthe?llerisnotanimportantvari-ableexceptwhenitiswithinafactorof10ofthethermalconductivityofthepolymericmatrix(adhesive).Mostmetal?llershavethermalconductivitiesgreaterthan10timesthematrixthermalconductivity(HermansenandTunick,1989).

Aluminapowderisoneofthecommonlyused?llersforimprovingthethermalconductivityofadhesives,inpartic-ularinsulationadhesives.Aluminumandsilverpowdersor?akesareusedtoimprovethethermalandelectricalconduc-tivitiesforadhesivesintendedtobeanelectricalorthermalpath(HermansenandTunick,1989;KangandPurushothaman,1998;Luetal.,1999).The?llerlevelmustbesuf?cientlyhightoachievepoint-to-pointcontactbeforeelectricalconductiv-ityisattained(HermansenandTunick,1989).However,toohigh?llercontentmightcauseadegradationinmechani-calpropertiesoftheadhesive(Nikkeshietal.,1998).Therearealsoseveralcommerciallyavailableepoxyadhesivesrein-forcedwithothermetal?llerssuchasaluminumpowder.

Whiletheimprovementonthermalpropertiesofadhesivesbyadditionofmetal?llersisobvious(HermansenandTunick,1989;TomlinsonandStapley,1977;LeeandNeville,1967;Kingery,1960;NieberleinandSteverding,1977),theirin?uenceonthemechanicalpropertiesoftheadhesivejointsarenotclear.Theresultsofthisstudyareexpectedtoshedlightonthisaspect.Theobjectivewastoinvestigatethein?uenceofthe?llercontentandtheadhesivethicknessonthemechan-icalperformanceofaluminumsingle-lapjointsbondedwithaluminumpowder?lledepoxyadhesive.

Thetraditionalevaluationofadhesivejointsbystrengthmeasurementswasutilizedinthestudy.Theadhesivestrengthwasdeterminedbyutilizingthesingle-lapsheartest(Mohan,1990;Arnold,1989;TsaiandMorton,1994;AnnualBookofASTMStandards,1992).Thesingle-lapjointcon?g-uration(Fig.1)iswidelyusedintheaerospace,automotiveandwoodandplasticindustries(HermansenandTunick,1989;Arnold,1989;Stringer,1985;DeWildeetal.,1995;JialanellaandShaffer,1993).Single-lapspecimensareeconomical,practicalandeasytomake.Theyalsoalloweasycontrol(andmeasure-ment)ofthebond

thickness.

Fig.1–Single-lapshearjointcon?guration.

Thevariationofadhesionstrengthwithadhesivethick-nessisexaminedinthispaper.Theeffectofbondthicknessonadhesiveperformanceforvariousotherjointshasbeenreportedbyfewinvestigators(Stringer,1985;Foulkesetal.,1970;Hylands,1984;Beevers,1986).However,thereisalackofstudyonthevariationofadhesioncharacteristicswithadhe-sivethicknessforsingle-lapshearjoints.Consequently,inthepresentstudy,theeffectsofmetal?lleradditionandtheadhe-sivethicknessonstressdistributionwithintheadhesivejointsareanalyzedbythe?niteelementmethod.Theexperimentsarealsocarriedouttovalidateandcomparethetheoreticalpredictionsoftheadhesionstrengthofadhesivebondsatdif-ferentthicknesses.

2.

Experimental

2.1.

Materials

Theepoxyadhesiveusedinthisinvestigationisageneral-purpose,two-partepoxy(Fusor309)obtainedfromLordCorporation.Theadhesiveispreparedbymixingequalvol-umesoftheresinandhardenerparts.Themixedadhesivecuresfullyin24–48hatroomtemperaturewithhandlingstrengthinabout8h.

Thealuminumpowderusedfor?llingtheepoxyadhesivewasobtainedfromAlliedBritanniaLimited.Thealuminumparticles(?ller)werespherical/roundishwithsizesmallerthan50?mindiameter.

Thealuminumsheetsusedasadherentsinmakingalu-minumjointswerecutfromlocallyobtainedaluminumplates.

2.2.Adhesivejointpreparation

Thefollowingprocedureswereusedforcleaningthealu-minumsheets(80mm×25.4mm)beforeadhesivelyjoiningthem(KozmaandOlefjord,1987a;Prakashetal.,1987;Semerdjiev,1970).

1.Degreasebydippingshortlyintrichloroethyleneandiso-propylalcohol,separately.2.Washwithwater.

3.Roughensurfacesbyabradercleaning(mechanicalclean-ing)by400gritsiliconcarbidegrindingpaper.

4.Degreasebydippingintrichloroethyleneandisopropylalcohol(30mineach).

journalofmaterialsprocessingtechnology205(2008)183–189

185

Fig.2–Finiteelementmodelofthesystem.

5.Immersefor2–4hinasolutionofH2SO4,sodiumdichro-mateanddistilledwaterinproportion:22.5,7.5and70byweight,respectively(chromic–sulphuricetchingprocess).6.Washwithdistilledwater.

7.Drywithcleanpaperortissueandkeepinadesiccatoruntiluse.Thesingle-lapshearadhesivejointswerethenpreparedbybondingsurfacecleaned/treatedaluminumsheetstogetherwithneatepoxyadhesiveandthenafteradditionofaluminumpowderatseveralfractions(10,25and50wt%).Equalvolumesoftheepoxyresinandthehardenerweremixedandthenalu-minumpowderwasaddedintotheadhesivemixingagain.Adesigned?xturewasusedtoassembletheadhesivejoints.Ithadtwo?xedendplatesandamovableonebetweenthem.Themetalsheetswerebondedtogetherbetweenthemovableplateandthefarendplate.The?xtureincludedamicrometerusedforcontrollingtheadhesivethickness.Theactualadhe-sivethicknessofthecuredjointwasmeasuredbyaDigimaticCaliper.

2.3.Mechanicalcharacterizationoftheadhesivejoints

Theadhesivejointswereassembledandtestedasspeci?edinASTMD1002(AnnualBookofASTMStandards,1992).Thejointcon?gurationisshowninFig.1whiletheappliedloadsareshowninFig.2.Endtabsofthesamethicknessandmate-rialoftheadherendswereusedtoplacetheloadaxisinthesameplaneoftheoverlaparea.TheequipmentusedformechanicalcharacterizationwasanInstron5567mechani-caltestingsystem.Jointstrengths,reportedinunitsofshearstress,werecalculatedasfollows:jointstrength=

failureloadadhesivelaparea

(1)

3.Stressanalysisby?niteelementmethod

Thein?uenceofmetal?llercontentandtheadhesivethick-nessonstressdistributionwithintheadhesivejointswasanalyzedby?niteelementmethod(FEM).Dueitsversatilityandcomputationalpower,theFEMiscommonlyusedintheanalysisofmodernengineeringandscienti?csystems.Inthisstudy,theFEMisusedtomodelandanalyzetheadhesivejointthroughthewell-known?niteelementpackageANSYS.Thesystemconsistingofthejointandtwo-bondedaluminumspecimensissubjectedtotension.TheresultingshearandvonMisesstressesarecomputedforvariousadhesivecompo-sitionsandthicknessestoseetheireffectsonthemechanicalstrengthofthejoint.Thesestressesarechosen,becauseit

is

Fig.3–Theelasticbeamelement.

expectedthattheshearstressisthemodeoffailurefortheadhesivejointandthevonMisesstressisameasureonthestateofequivalentstress.

The?niteelementmodelofthesystemisshowninFig.2.Thetwoaluminumspecimensseeninthe?gurearemodeledusingtheBEAM3elementinANSYS(ANSYS,2005).DepictedinFig.3,thiselasticbeamelementallowsin-planehorizontalandverticaldisplacements(uandv)androtationabouttheout-of-planeaxis(?)atthetwoendnodesof1and2.AsshowninFig.3,thegrippedportionoftheleftspecimenis?xedandtherightspecimenispulledwithaforce(F)of100Nresemblingtheactualtestingconditions.Intheactualtest,thisforceisalignedwiththecentralaxisofthejointandhenceabendingmomentofM=Ft/2isappliedtoaccountfortheeccentricityoftheforceatthe?niteelementmodel(wheretistheadhesivethickness).

Thetwodimensional(2D)quadrilateralelementwithmid-sidenodesandthicknessoption,PLANE82,wasusedformodelingtheadhesivebondgivingin-planedisplacementsattheeightnodes.Thiselementisahigherversionofthefour-nodedelementinANSYSandisbettersuitedfortheapplicationswherethebendingmomentexists(ANSYS,2005).Theadhesivebondismadeofepoxyandaluminum?llerwhoseweightpercentagesarechangedtogetherwiththebondthickness(t)toobservetheireffectsonthemechanicalstrengthofthejoint.ThematerialpropertiesforthealuminumandepoxyarelistedinTable1.Themodulusofelasticity(E)andPoisson’sratio(??)fortheadhesiveareassumedasE=caEa+ceEe(2)??=ca??a+ce??e

(3)

whereEaandEearethemoduliofelasticity,and??aand??earethePoisson’sratiosforthealuminumandepoxy,respectively.Thecoef?cientscaandceintheaboveequationsdenotethefractionscorrespondingtothealuminum?llerandepoxy.

Table1–Materialproperties

Aluminum

Epoxy

Modulusofelasticity(E,GPa)68.951.0858Poisson’sratio(?)

0.333

0.38

186

journalofmaterialsprocessingtechnology205(2008)

183–189

Fig.4–Aplotofadhesivejointstrengthvs.adhesivethicknessforaluminumjointsbondedwithneatepoxywithno?ller.

4.

Resultsanddiscussion

4.1.

Mechanicalcharacterization

AdhesivejointstrengthversusadhesivethicknessisplottedinFig.4foraluminumjointsbondedwithneatepoxywithno?llercontent.Adhesivethicknessesinvestigatedrangedfrom0.03mmto1.3mm.Asseenintheplotthereisageneraltrendofdecreaseinsingle-lapadhesivejointshearstrengthwithadhesivethickness.Increaseofadhesivethicknessfrom0.03mmto1.3mmresultedadecreaseofabout35–40%inadhesivejointshearstrength.Howevertheeffectwasnotsig-ni?cantforadhesivethicknessesuptoabout0.7mm.

Inlightoftheaboveresult,thesmallestadhesivethickness(0.03–0.05mm)wasusedfortheexperimentsoftherestoftheinvestigation.

Aplotofadhesivejointstrengthversusamountofalu-minumpowderusedintheadhesiveispresentedinFig.5.Additionofaluminumparticlesasmuchas50wt%didnotcauseasigni?cantdecreaseinadhesivejointstrength.

It

Fig.5–Aplotofadhesivejointstrengthvs.adhesive?ller

content.

Fig.6–Fracturesurfacesofanaluminumjointbondedbyepoxywithnometal

?ller.

Fig.7–Fracturesurfacesofanaluminumjointbondedbyepoxywith25wt%aluminum?ller.

shouldbenotedthat50wt%Al?llercontentintheadhesivecorrespondstoabout44.45%involumebecauseofdensitydifferencebetweenaluminumparticlesandepoxyadhesive.

Fracturedspecimenswerevisuallyexaminedtodeterminethefailuremode.Thejointsfailedalmostcompletelyincohe-sivefailuremode.Cohesivefailureoccurswhentheadhesiveseparatesfromitself(failurewithinadhesive).AdhesivelayersleftonbothjointsurfacesareclearlyshowninFigs.6and7forneatepoxyandepoxywith25wt%aluminum?llercontent,asexamples.

4.2.FEManalysis

TheshearandvonMisesstressesforvariousbondthick-nessesandvariousadhesivecompositionswereanalyzed.Accordingtothestresscontourswhicharenotshownhere,themaximumshearandvonMisesstressesoccurattheadhesive–metalsubstrateinterface.Thisisespeciallytruefortheshearstresses,whichalmostvanishtowardthemiddleoftheadhesive.ThesametrendalsoexistsforthevonMises

journalofmaterialsprocessingtechnology205(2008)183–189

187

Fig.8–Maximumshearstressvs.adhesivethicknessforneatepoxy.

stresses,whichattainmaximumattheedgesanddecreaseawayfromtheedges.

Inordertoinvestigatetheeffectofbondthicknessonthebondstrength,themaximumshearandvonMisesstressesareplottedagainstthebondthicknessforneatepoxyadhesiveinFigs.8and9.Asseeninthese?guresshearstressesintheadhesiveincrease(decreasingthebondstrength)asthebondthicknessincreases.AsforthemaximumvonMisesstresses,theyshowslightlydifferentormixedbehavior(Fig.9),butthegeneraltrendissimilartothetrendfortheshearstresses.Inotherwords,thevonMisesstressesarealsoincreasedasthethicknessofthebondisincreased.ItshouldbenotedthattheshearstresscontributiontothevonMisesstressissigni?cantinthebondregionclosetothealuminumplate.This,inturn,resultsinpossiblefailureofbondinginthisregion.

Fig.10showstheplotsof?niteelementpredictionsandexperimentalresultsfortheadhesivejointstrengthofneatepoxyatdifferentadhesivethicknesses.Itcan

be

Fig.9–MaximumvonMisesstressvs.adhesivethicknessforneat

epoxy.

Fig.10–Adhesivejointstrengthvs.adhesivethicknessforneat

epoxy.

Fig.11–Variationofmaximumshearstresswith

aluminumcontentforadhesivethicknessof0.05mm.

observedthatthe?niteelementpredictionsagreewellwiththeexperimentalresults.Somediscrepanciesbetweenbothresultsarebecauseof(i)theexperimentalerror,whichisestimatedas7%(basedontheexperimentalrepeats)and(ii)theassumptionofthehomogeneousadhesiveprop-ertiesacrossthebondingsectioninthe?niteelementsimulations.

Stressanalysiswasalsodoneforvariousadhesivecompo-sitions.Themassaverageofmechanicalpropertieswasusedinsimulationstoaccountforthealuminumpowderconcen-trationintheadhesivecomposition.Figs.11and12showtheplotsofthemaximumshearandvonMisesstressesversusadhesivecompositionsforthebondthicknessof0.05mm.Itisevidentthatthesestressesgethigherastheweightpercent-ageofaluminumcontentintheadhesivebondincreases.Inotherwords,thealuminumcontentintheadhesiveadverselyaffectstheadhesionstrengthofthejoint.However,asthebondthicknessincreasesthiseffectdiminishesandtherateofincreaseinstressestendstodecreaseathighbondthick-

188

journalofmaterialsprocessingtechnology205(2008)

183–189

Fig.12–MaximumvonMisesstressvs.aluminumcontentforadhesivethicknessof0.05mm.

nesses.Resultsfortheadhesivethicknessof1.0mmarepresentedinFigs.13and14.

Furthermore,asstatedinthemanuscriptinSection3,theshearstressisthepossiblecauseoffailurefortheadhesivejoint.Hence,asseeninFigs.11and13,themaximumshearstressis,ingeneral,higherfortheadhesivethicknessof1mmthanthatcorrespondingtothethicknessof0.05mm.Thisresultindicatestheadverseeffectoftheadhesivethicknessincreaseinbondstrength.

Althoughinthepresentstudy,aluminumpowderisusedas?llerintheadhesive,investigationintomechanicalresponseofthejointwhenotherpowdersuchascopperwillbefruitfulforfutureinvestigation.Inaddition,examinationofthemechanicalresponseofthejointsduetomixtureofaluminumandcopperpowdersusedas?llerintheadhe-sivewillbeinterestingforimprovedthermalandelectrical

conductivities.

Fig.13–Variationofmaximumshearstresswithaluminumcontentforadhesivethicknessof1

mm.

Fig.14–MaximumvonMisesstressvs.aluminumcontentforadhesivethicknessof1mm.

5.Conclusions

Thefollowingstatementscanbemadefromthe?ndingsofthisstudy:

1.AccordingtotheresultsofbothFEManalysisandtheexper-imentalinvestigation,adhesivethicknesshasanegativeeffectonsingle-lapadhesivejointshearstrength.

2.The?niteelementresultsonstressesshowthatthealu-minumcontentintheadhesiveadverselyaffectsthemechanicalstrengthofthebond.

3.However,apromisingresultwasobtainedthroughexper-imentalinvestigationthatepoxyadhesiveretainsitsadhesionstrengthevenwithasmuchas50wt%additionofaluminum?ller.

4.Eventhoughthe?niteelementanalysisshowshigherstressesattheadhesive–metalsubstrateinterface,actualfailureoccurswithintheadhesiveindicatingthatthestrengthofadhesiontothemetalsubstratesurfaceisstrongerthanthestrengthoftheadhesiveitself.

Acknowledgment

ThisstudyhasbeenfundedbyKingFahdUniversityofPetroleum&MineralsundertheProject#SAB-2003/12.

references

AnnualBookofASTMStandards,1992.AmericanSocietyfor

TestingandMaterials,vol.15.06.ASTM,Philadelphia,PA,pp.47-50.

ANSYS,2005.Release10.0,ANSYS,Inc.,Canonsburg,

Pennsylvania,USA.

Arnold,J.R.,July1989.Adhesivelybondedcoatedsteels.Automot.

Eng.,39–44.

Beevers,A.,1986.Coaxialjointsinengineeringassembly.Mater.

Sci.Technol.2,97–102.

journalofmaterialsprocessingtechnology205(2008)183–189

189

Brewis,D.M.,1985.Factorsaffectingbondingofmetals.In:

ContinuousCasting’85,ProceedingsoftheInternationalConferenceSponsoredandOrganizedbyTheInstituteofMetals,London,pp.629–644.

Chasser,A.M.,Makhlouf,J.M.,Schneider,J.R.,March1993.

Rubber-basedstructuraladhesiveisanewoptionformetalbonding.Adhes.Age,36–39.

DeWilde,W.P.,VanVinckenroy,G.,Tirry,L.,Cardon,A.H.,1995.

Effectsoftheenvironmentandcuringonthestrengthofadhesivejoints.J.Adhes.Sci.Technol.9,149–158.

Foulkes,H.,Shields,J.,Wake,W.C.,1970.Thevariationofbond

strengthwithtemperature:apreliminarystudyofmetal-to-metaladhesion.J.Adhes.2,254–269.

Gaynes,M.A.,Matienzo,L.J.,Zimmerman,J.A.,Vanchart,D.,1997.

Analysisandcharacterizationofelectricallyconductiveadhesives.In:ElectronicPackagingMaterialsScience.IX.MaterialsResearchSocietySymposiumProceedings,Warrendale,PA,USA,pp.139–151.

Hahn,O.,Meschut,G.,Koyro,M.,1998.Thermalconductivity,

strengthandageingbehaviourofadhesive-bondedjointswith?ller-modi?edadhesives.SchweissenundSchneiden/Weld.Cutting50(7),E130–E133.

Hermansen,R.D.,Tunick,S.A.,October1989.Formulating

custom-tailoredthermaltransferadhesives.Adhes.Age,38–41.

Hogg,I.C.,Janardhana,M.N.,1993.Surfacepreparationof

adhesivelybondedjoints.In:Chandra,T.,Dhingra,A.K.(Eds.),AdvancedComposites’93,InternationalConferenceonAdvancedCompositeMaterials.TheMinerals,Metals&MaterialsSociety,pp.455–461.

Hylands,R.W.,1984.Strengthcharacteristicsofmonoand

multiple-wiresteeltosteeljointsbondedwithanepoxyadhesive.In:Mittal,K.L.(Ed.),AdhesiveJoints:Formation,Characteristics,andTesting.PlenumPress,NewYork,pp.165–193.

Jialanella,G.L.,ShafferII,E.O.,1993.Theeffectofadhesive

modulusontheperformanceofSMClapshearjoints.J.Adhes.Sci.Technol.7,1171–1181.

Kang,S.,Purushothaman,S.,1998.Developmentoflowcost,low

temperatureconductiveadhesives.In:ProceedingsoftheElectronicComponentsandTechnologyConference,IEEE,Piscataway,NJ,USA,pp.1031–1035.Kingery,W.D.,1960.IntroductiontoCeramics.JohnWiley&Sons,

Inc.,NewYork.

Kinloch,A.J.,1983.DurabilityofStructuralAdhesives.Applied

SciencePublishers,London.

Kozma,L.,Olefjord,I.,1987a.Basicprocessesofsurface

preparationandbondformationofadhesivelyjoinedaluminum.Mater.Sci.Technol.3,860–874.

Kozma,L.,Olefjord,I.,1987b.Surfacetreatmentofsteelfor

structuraladhesivebonding.Mater.Sci.Technol.3,954–962.Lee,H.,Neville,K.,1967.HandbookofEpoxyResins.McGraw-Hill,

NewYork.

Lu,D.,Tong,Q.K.,Wong,C.P.,1999.Conductivitymechanismsof

isotropicconductiveadhesives(ICA’s).IEEETrans.Electron.Pack.Manuf.22(3),223–227.

Mohan,R.,February1990.Analyzingadhesivelybondedjointsfor

automotiveapplications.Plast.Eng.,47–51.

Nieberlein,V.A.,Steverding,B.,1977.Thermalconductivityof

epoxy–aluminumpowdermixtures.J.Mater.Sci.Lett.12,1685–1688.

Nikkeshi,S.,Kudo,M.,Masuko,T.,1998.Dynamicviscoelastic

propertiesandthermalpropertiesofNipowder–epoxyresincomposites.J.Appl.Polym.Sci.69(13),2593–2598.

Prakash,R.,Srivastava,V.K.,Gupta,G.S.R.,December1987.

Behaviorofadhesivejointsincorrosiveenvironment.Exp.Mech.,346–351.

Semerdjiev,S.,1970.Metal-to-MetalAdhesiveBonding.Business

BooksLimited,London.

Stringer,L.G.,1985.Comparisonoftheshearstress–strain

behaviourofsomestructuraladhesives.J.Adhes.18,185–196.Subramanian,S.,Kustas,F.,Rawal,S.,Shinn,E.T.,1998.

Fabrication,testingandanalysisofcarbon-carbon/aluminumbondedjointswithhighthermalconductivity.In:CollectionofTechnicalPapers—AIAA/ASME/ASCE/AHS/ASCStructures,StructuralDynamics&MaterialsConference,vol.3,AIAA,Reston,VA,USA,pp.2423–2433.

Tai,R.C.L.,Szklarska-Smialowska,Z.,1993.Absorptionofwater

bydifferent?llers-incorporatedautomotiveepoxyadhesives.J.Mater.Sci.28,6199–6204.

Tomlinson,W.J.,Stapley,D.,1977.Thermalconductivityofepoxy

resin–aluminum(0–50%)composites.J.Mater.Sci.Lett.12,1689–1690.

Tsai,M.-Y.,Morton,J.,1994.Anoteonpeelstressesinsingle-lap

adhesivejoints.J.Appl.Mech.61,712–715.

本文标题:adhesive-epoxy adhesive61阅读| 精彩专题| 最新文章| 热门文章| 苏ICP备13036349号-1