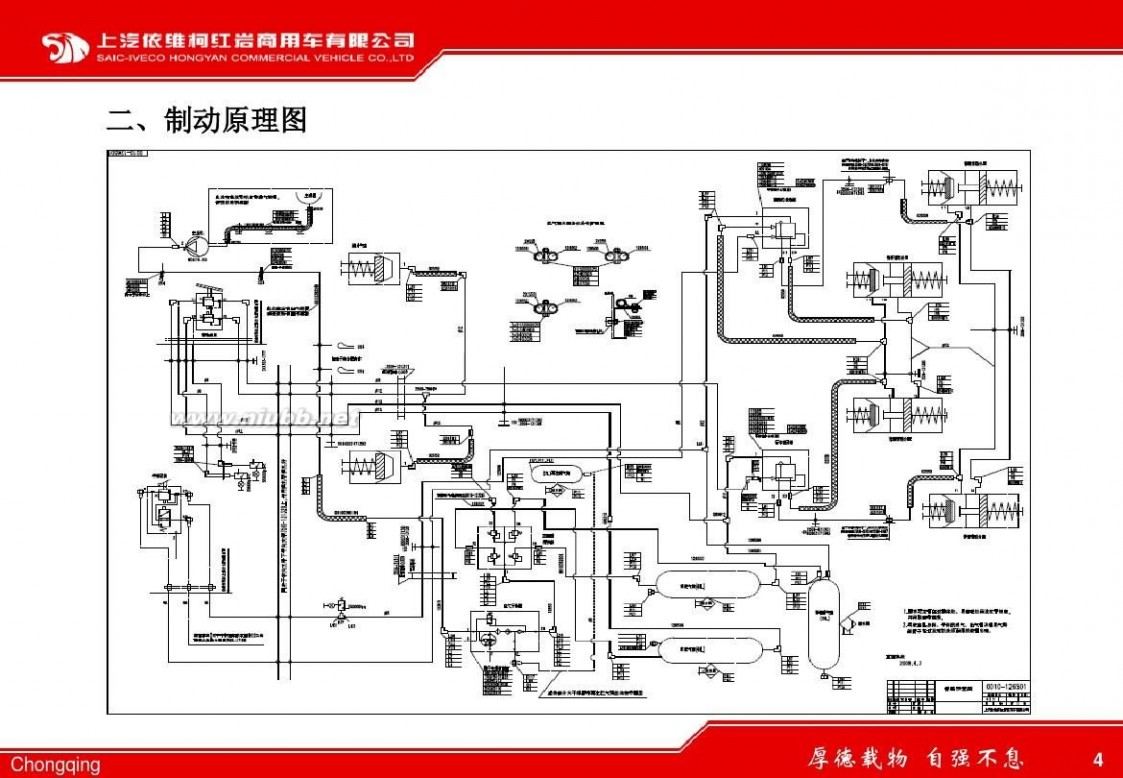

一 : 汽车制动系统组成和原理

制动系统(10)汽车(491)汽车制动系统组成和原理

组成

(1)供能装置:包括供给、调节制动所需能量以及改善传动介质状态的各种部件

(2)控制装置:产生制动动作和控制制动效果各种部件,如制动踏板

(3)传动装置:包括将制动能量传输到制动器的各个部件如制动主缸、轮缸

(4)制动器:产生阻碍车辆运动或运动趋势的部件

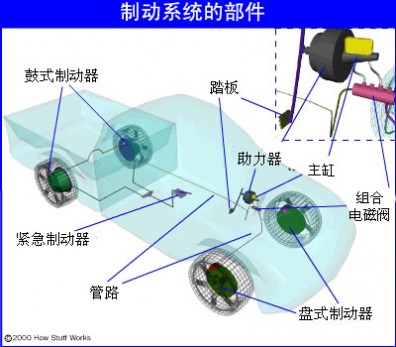

制动系统一般由制动操纵机构和制动器两个主要部分组成。

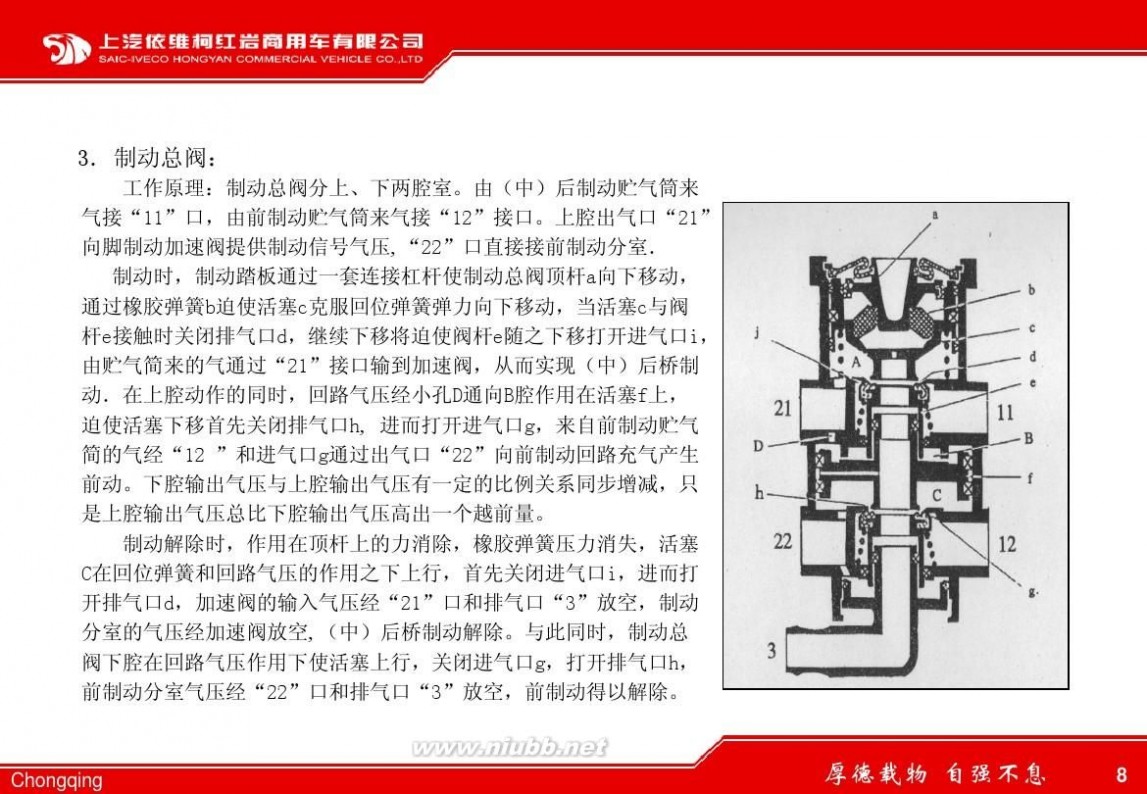

(1)制动操纵机构

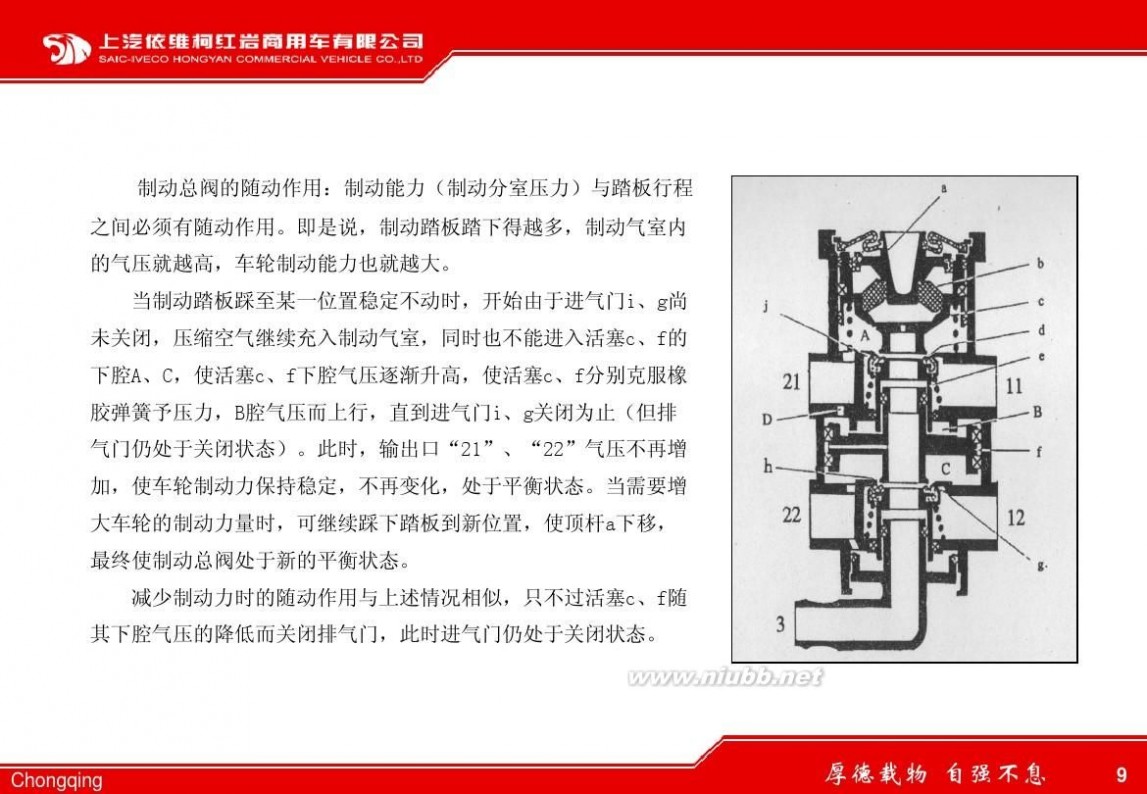

产生制动动作、控制制动效果并将制动能量传输到制动器的各个部件,如图中的2、3、4、6,以及制动轮缸和制动管路。

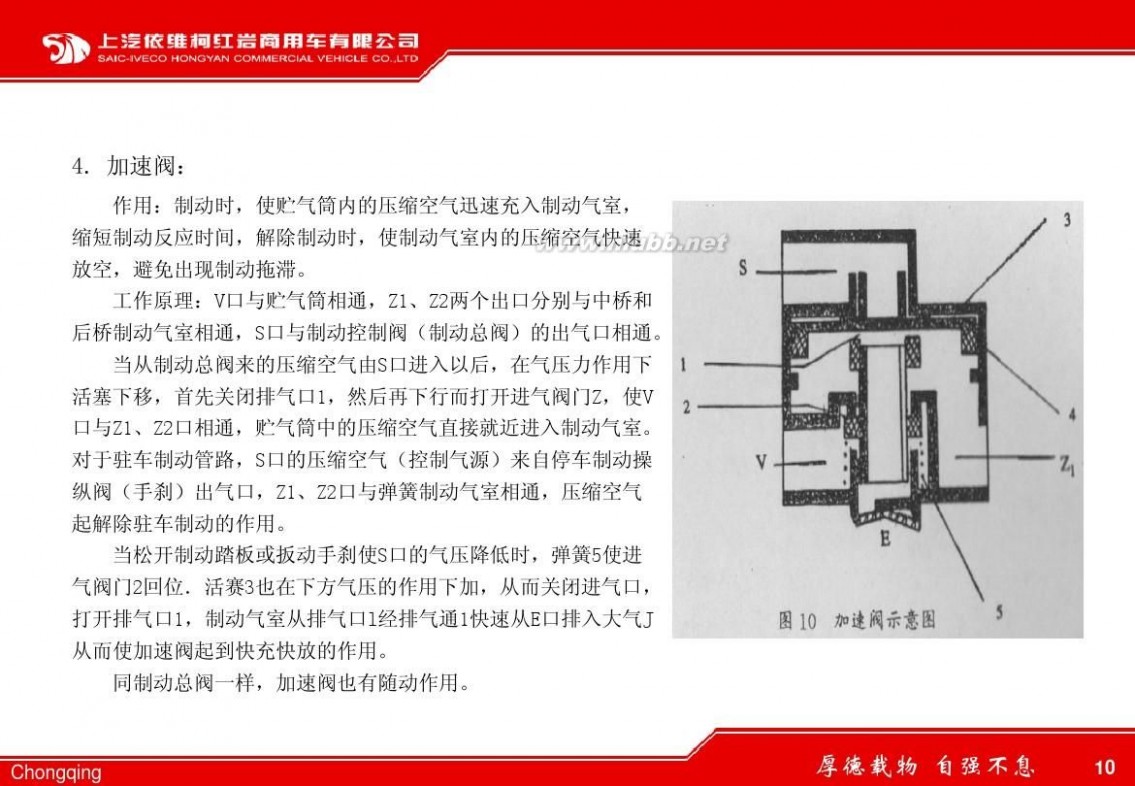

(2)制动器

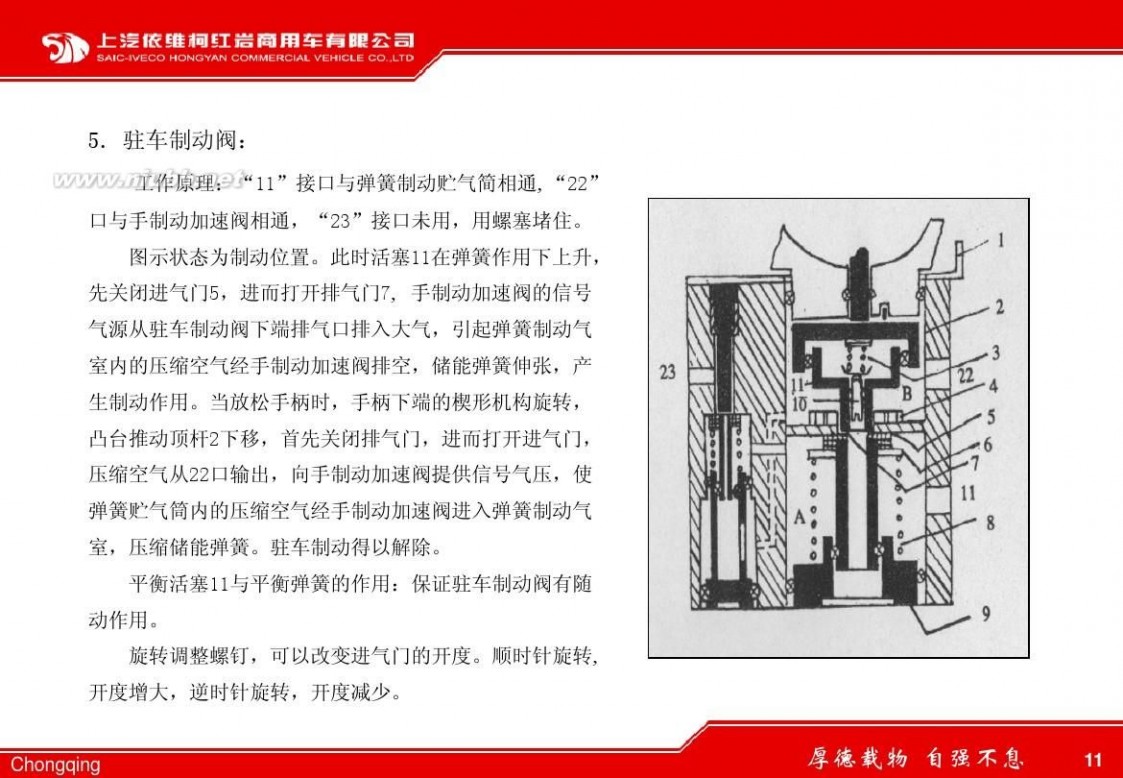

产生阻碍车辆的运动或运动趋势的力(制动力)的部件。汽车上常用的制动器都是利用固定元件与旋转元件工作表面的摩擦而产生制动力矩,称为摩擦制动器。它有鼓式制动器和盘式制动器两种结构型式。

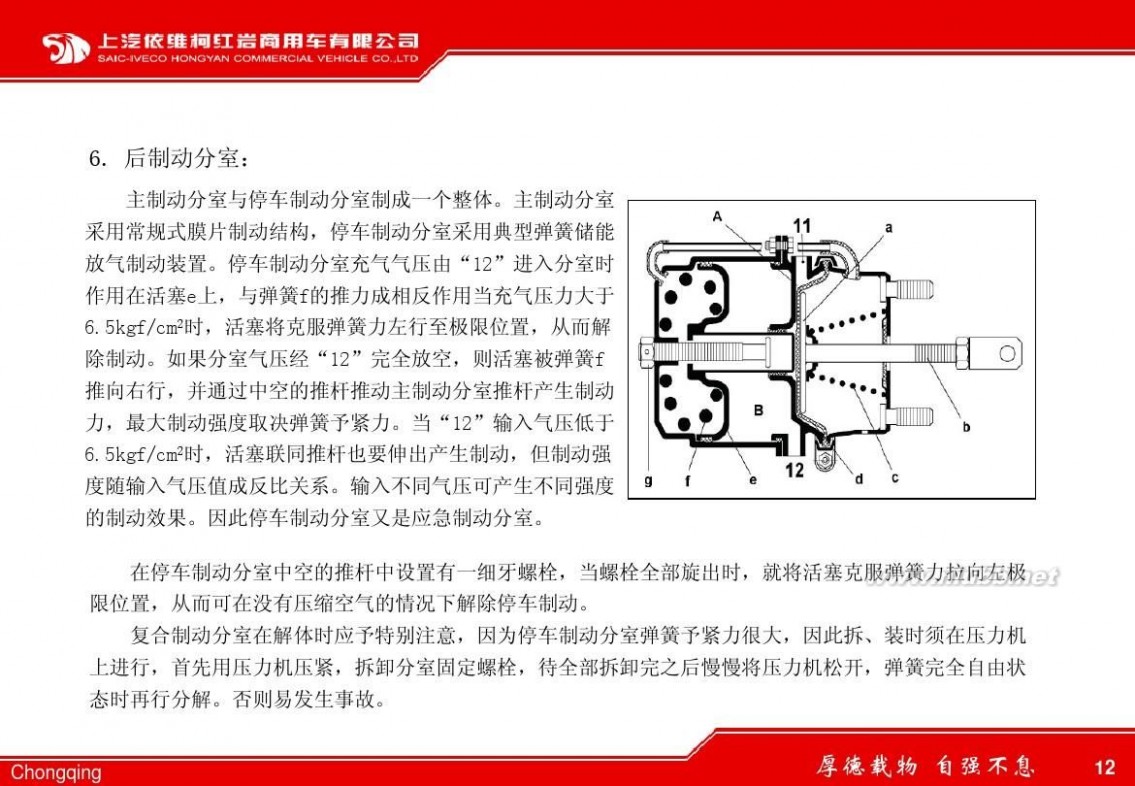

原理

1、一般制动系的基本结构

·主要由车轮制动器和液压传动机构组成。

·车轮制动器主要由旋转部分、固定部分和调整机构组成,旋转部分是制动鼓;固定部分包括制动蹄和制动底板;调整机构由偏心支承销和调整凸轮组成用于调整蹄鼓间隙。

·制动传动机构主要由制动踏板、推杆、制动主缸、制动轮缸和管路组成。

2、制动工作原理

制动系统的一般工作原理是,利用与车身(或车架)相连的非旋转元件和与车轮(或传动轴)相连的旋转元件之间的相互摩擦来阻止车轮的转动或转动的趋势。

1)制动系不工作时

·蹄鼓间有间隙,车轮和制动鼓可自由旋转

2)制动时

·要汽车减速,脚踏下制动器踏板通过推杆和主缸活塞,使主缸油液在一定压力下流入轮缸,并通过两轮缸活塞推使制动蹄绕支承销转动,上端向两边分开而以其摩擦片压紧在制动鼓的内圆面上。不转的制动蹄对旋转制动鼓产生摩擦力矩,从而产生制动力

3)解除制动

·当放开制动踏板时回位弹簧即将制动蹄拉回原位,制动力消失。

3、制动主缸的结构及工作过程

·制动主缸的作用是将自外界输入的机械能转换成液压能,从而液压能通过管路再输给制动轮缸

·制动主缸分单腔和双腔式两种,分别用于单、双回路液压制动系。

(1)单腔式制动主缸

1)制动系不工作时

·不制动时,主缸活塞位于补偿孔、回油孔之间

2)制动时

·活塞左移,油压升高,进而车轮制动

3)解除制动

·撤除踏板力,回位弹簧作用,活塞回位,油液回流,制动解除

(2)双腔式制动主缸

1)结构(如一汽奥迪100型轿车双回路液压制动系统中的串联式双腔制动主缸)

·主缸有两腔

·第一腔与右前、左后制动器相连;第二腔与左前、右后制动器相通

·每套管路和工作腔又分别通过补偿孔和回油孔与储油罐相通。第二活塞由右端弹簧保持在正确的初始位置,使补偿孔和进油孔与缸内相通。第一活塞在左端弹簧作用下,压靠在套上,使其处于补偿孔和回油孔之间的位置。

2)工作原理

·制动时,第一活塞左移,油压升高,克服弹力将制动液送入右前左后制动回路;同时又推动第二活塞,使第二腔液压升高,进而两轮制动

·解除制动时,活塞在弹簧作用下回位,液压油自轮缸和管路中流回制动主缸。如活塞回位迅速,工作腔内容积也迅速扩大,使油压迅速降低。储液罐里的油液可经进油孔和活塞上面的小孔推开密封圈流入工作腔。当活塞完全回位时,补偿孔打开,工作腔内多余的油由补偿孔流回储液罐。若液压系统由于漏油,以及由于温度变化引起主缸工作腔、管路、轮缸中油液的膨胀或收缩,都可以通过补偿孔进行调节。

4、制动轮缸的结构及工作过程

·制动轮缸的功用:是将液力转变为机械推力。有单活塞和双活塞两种。

1)结构

·奥迪100的双活塞式轮缸体内有两活塞,两皮碗,弹簧使皮碗、活塞、制动蹄紧密接触。

2)工作过程

·制动时,液压油进入两活塞间油腔,进而推动制动蹄张开,实现制动。

·轮缸缸体上有放气螺栓,以保证制动灵敏可靠。

典型的制动系统 |

本文是制动系统六个部分的第一部分,我们将按踏板到车轮的顺序,从头到尾详细讲述制动系统的各个部分。本文将介绍汽车制动系统的基本概念,并分析一个简单制动系统的工作原理。在其他文章中,我们将向您介绍汽车制动系统的其他部件,并详细讲述每个部件的工作原理。

| 关于制动系统的其他文章主缸和组合阀工作原理鼓式制动器工作原理盘式制动器工作原理动力制动系统工作原理防抱死制动系统工作原理 |

您踩下制动踏板以后,汽车通过制动液将您的脚下发出的力传递到制动器。而制动实际上需要的力要远远大于您的脚所施加的力,因此汽车必须将您的脚施加的力放大。放大的方式有两种:

机械效益(杠杆作用)液压放大制动器通过摩擦将制动力传递到轮胎,轮胎则通过摩擦将制动力传递到路面。在开始讨论制动系统的各部件之前,先让我们熟悉一下以下三条原理:

杠杆作用液压作用摩擦力作用杠杆作用

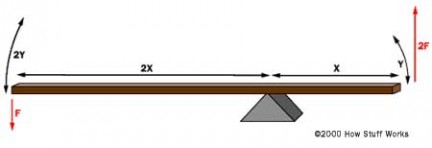

制动踏板以如下方式设计,它可以将您腿部发出的力在传递到制动液之前就放大几倍。

|

如上图所示,在杠杆的左端施加一个力F。杠杆左端的长度(2x)是右端(x)的两倍。因此,我们可以在杠杆右端获得一个2F的力,它运动的位移(y)则只是左端位移(2y)的一半。改变杠杆左右两端的相对长度,也就改变了放大系数。

液压系统

任何液压系统的基本原理都很简单:作用于某一点的力被不能压缩的液体传递到另一点,这种液体通常是油类液体。 绝大多数制动系统都是通过这一过程放大制动力的。下面是一个最简单的液压系统:

如上图所示:两个活塞(红色)分别装在充满油(蓝色)的两个玻璃圆桶中,圆桶之间由一个充满油的导管连接。如果给一个活塞(图中左边的活塞)施加一个向下的力,那么这个力就可以通过管道内的液压油传递到另一个活塞。由于油不能被压缩,所以这种传递方式的效率非常高,几乎所有的力都传递给了第二个活塞。液压系统最大的好处就是,连接两个液压缸的导管可以是任何长度,也可以曲折成各种形状以绕过中间的其他部件。此外,还有一个好处就是液压管可以分支,这样一个主缸就可以被分成多个副缸,如下图所示:

使用液压系统的另一个好处就是力的放大或缩小相当容易。如果您读过滑轮组的工作原理或齿轮比原理,您就会知道,用力换取位移在机械系统中极为常见。在液压系统中,您要做的就是改变其中一个活塞及其配套液压缸的尺寸,如下图所示:

上图中,力的放大倍数取决于活塞的直径。假设左边的活塞直径为5厘米,即半径为2.5厘米;右边的活塞直径为15厘米,即半径为7.5厘米。两个活塞的面积可以通过公式A=2πr2计算得出。左边活塞的面积为19.6平方厘米,右边活塞的面积为176平方厘米。右边活塞的面积是左边活塞的九倍。这就意味着给左边的活塞施加任何一个力,右边的活塞就会产生一个九倍的力。因此,如果给左边的活塞施加一个100公斤的向下的力,右边的活塞就会产生一个900公斤的向上的力。 唯一的不足就是当左边的活塞向下移动9厘米时,右边的活塞只能向上移动1厘米。

摩擦力

摩擦力是一个物体在另一个物体上滑动时受到的阻力。请看下图,两个滑块都是用相同材料做成的,但其中一个较另一个更重。所以不难看出哪一个更难推动。

摩擦力与重量 |

我们可以通过近距离地观察其中一个滑块和桌面来了解其中的原因:

通过显微镜来研究摩擦力 |

用肉眼看起来很平滑的接触面,在显微镜下观察却是相当粗糙的。把滑块平放在桌面上时,滑块和桌面之间有许多小锯齿挤在一起,其中一些会相互咬合。滑块重量越大,咬合的锯齿就越多,其滑动阻力也会越大。

不同的材料具有不同的微观结构。例如,橡胶与橡胶之间就比钢铁与钢铁之间更难滑动。材料的类型决定了摩擦系数,此系数等于推动滑块所需的作用力与滑块重量的比值。在上例中,如果摩擦系数为1.0,那么推动重100公斤的滑块需要施加100公斤的力,推动重400公斤的滑块需要施加400公斤的力。如果摩擦系数为0.1,那么10公斤的力就可以推动重100公斤的滑块,而推动重400公斤的滑块也只需施加40公斤的力。

所以推动滑块所需的作用力与其重量成正比。滑块越重,推动它所需的作用力就越大。这一原理适用于制动器与离合器这样的装置,在这种装置上,制动片紧压着旋转盘。制动片受到的压力越大,汽车的制动力就越大。

| 摩擦系数 关于摩擦力的一个有趣现象是,推动物体所需的力通常比使其持续运动所需的力要大。两个接触面在没有发生相对位移的情况下存在一个静摩擦系数。如果两个接触面发生了相对位移,那么克服摩擦力所需的力就取决于动摩擦系数,动摩擦系数通常小于静摩擦系数。 就汽车轮胎而言,其动摩擦系数远小于静摩擦系数。所以,当轮胎接触面与路面没有发生相对位移时,汽车轮胎提供的牵引力最大。当轮胎打滑(如刹车或熄火)时,牵引力会大大降低。 |

在了解实际的汽车制动系统的各个部件之前,我们先来看看一个简单的系统:

可以看到,踏板到制动轴的距离是制动缸到制动轴距离的四倍,所以在踏板上施加的力在传递到制动缸之前就会被放大四倍。

还可以看到,制动缸的直径是连接踏板的液压缸直径的三倍,这又把制动力放大了九倍。综上所述,此系统把您脚部发出的力放大了36倍。如果您对踏板施加了10公斤的力,那么在车轮处挤压制动片的力将达到360公斤。

另一方面。这个简单的制动系统还存在几个问题有待解决。渗漏会导致什么结果?如果发生缓慢的渗漏,最终将导致制动缸内的制动液不足,制动系统也会随之失效。反之,如果发生急剧渗漏,您第一次刹车时所有的制动液就会喷射而出,制动系统就会完全失灵。

现代汽车中的主缸就是为了解决这一问题而设计的。请阅读主缸和组合阀工作原理一文。有关制动系统的其他文章,请参加下一页上的链接。

二 : 汽车制动系统讲解

汽车制动系统 汽车制动系统讲解

汽车制动系统 汽车制动系统讲解

汽车制动系统 汽车制动系统讲解

汽车制动系统 汽车制动系统讲解

汽车制动系统 汽车制动系统讲解

汽车制动系统 汽车制动系统讲解

汽车制动系统 汽车制动系统讲解

汽车制动系统 汽车制动系统讲解

汽车制动系统 汽车制动系统讲解

汽车制动系统 汽车制动系统讲解

汽车制动系统 汽车制动系统讲解

汽车制动系统 汽车制动系统讲解

汽车制动系统 汽车制动系统讲解

汽车制动系统 汽车制动系统讲解

汽车制动系统 汽车制动系统讲解

三 : GMS_通用汽车全球制造系统

INTRODUCTION TO

GMS

GMS

Global Operating System

GMS

GMS Executive Overview (4-5 Hours)

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 1

GMS

? Classroom Norms

1. Pagers, phones - Please turn off or put on vibrate 2. If urgent call, please talk outside 3. Relax, ask questions and have fun!!

?Standardized Introductions

1. Name 2. Role 3. Main hobby

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 2

What Do We Need To Do To Meet Our Vision?

Customer Satisfaction

GMS

Customer Enthusiasm

?

GMS Executive Overview

GM Confidential Version Date 2004.8.12

?

John S. Hamalian

Slide 3

Customer Satisfaction is not good enough!!!

Who is the Customer?

External Customer (Buys Product)

GMS

Customer Enthusiasm

Internal Customer (YOU!)

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 4

What Makes Customer Enthusiasm?

Good Buying Experience

GMS

+

Good Ownership Experience

=

Customer Enthusiasm

Sales Marketing

GMS Executive Overview

Design Engineering Manufacturing After Sales

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 5

What Does Everyone Need to Get Customer Enthusiasm?

GMS

Safe, Clean & Healthy Environment VW ? People-Oriented Organisation ? Attractive, High Quality Products Toyota ? Good Customer Response ? High Customer Value

?

Ford

GM

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 6

Needs Translate to Goals…

GMS

THE 5 MAIN GOALS

SAFETY (Safe Work) PEOPLE (Organizational Development) QUALITY (Attractive Product) RESPONSIVENESS (Quantity/ Volume/Speed) COST (Good Value)

$

Focus on employee Development, Involvement and Enthusiasm Each customer in each process expects a high quality product or service Eliminate waste and control costs to deliver our customers the right product at the right price!!

Safe, Clean & Healthy Working Environment for all employees and visitors

Customers want a quality product or service but they also want it FAST!

Provide every product or service (exactly what the customer wants) defect free, on demand, with no waste and in a work environment where everyone is happy and safe.

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 7

The Goal Sequence Has A Meaning!

GMS

Always Remember The Priorities…

C

TRADITIONAL

$

R

Q

P

S

Traditionally, the organisation was focused around financial controls with Quantity as a priority – People development and Safety were not particularly important

S

MODERN

P

Q

R

C

$

Modern philosophy is that Safety is always First with a priority on People and Quality. If we focus on these things, Cost through waste reduction - will eventually decrease

GMS Executive Overview

GM Confidential Version Date 2004.8.12

J Hamalian

John S. Hamalian

Slide 8

How Do We Reach Our Goals?…

GMS

GMS

Global Operating System

It is a critical p

hilosophy to achieve our Vision

“One System”

-One ‘Language’ - One Umbrella - One Company Culture - One Mindset

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 9

Creation of GMS

OPEL (Eisenach) QN

GMS

NUMMI (TOYOTA)

GMNA (Green Book)

CAMI (Suzuki) Saturn

GMS not a only a “GM” system but is mostly modeled on Toyota & some Suzuki philosophy

GMS

(1996)

GMS was born out of the strategic need to adopt modern, lean thinking for corporate survival

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 10

What is Lean Thinking?

Mass vs. Lean Processes

GMS

? Buffered processes are protected against everything: unexpected quality problems, stoppages, high absenteeism, etc. ? Lean processes assure continuous flow with minimal waste by empowered teams and the quality should be achieved within the process

1800 (Craft)

Production System

1900 (Mass) Buffered or Mass (“Fordism”)

2000 (Lean) Lean (Toyota)

Buffers & Waste

Standardization Leader Span of Control Planning & Problem Solving

High

High, by managers Narrow Low (reactive)

Low

High, by teams Moderate High (proactive)

Degree of Correction

Teamwork & Empowerment Risk

GMS Executive Overview

High (inspect-out quality)

Low Low

GM Confidential Version Date 2004.8.12

Low (built-in quality)

High High

John S. Hamalian

Slide 11

Toyota Philosophy

GMS

? Strong Corporate Culture

? Balance Between Process and Results ? Commitment to Learning not Knowing

? Entire Organisation Knows and Uses the System

? Minimum barriers between functions and levels ? Focus on Long Term Results Respect For Humanity and Continuous Improvement through the Elimination of Waste are Foundation of Toyota?s System

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 12

Use GMS Principles To Obtain Our Goals

GOOD PROCESSES

Vision/ Mission

GMS

GOOD RESULTS

? Safety Goals & Metrics ? People (Results) ? Quality ? Responsiveness ? Cost

Business Goals (Scorecard )

Lean Principles (Process)

Standardization

Built-In-Quality

Short Lead Time

Continuous Improvement Company People Involvement Company

GMS Executive Overview

GM Confidential Version Date 2004.8.12

Methods to Meet the Goals (GMS)

John S. Hamalian

Slide 13

THE 5 GMS PRINCIPLES

People Involvement

People are the most valuable resource in the company

GMS

Standardization

Set and follow standards to achieve a base from which to grow Customer’s Quality expectations are built in to each process to ensure defects are not passed Reduce the time to deliver any product or service

Built-In-Quality

Do not

Accept Build Ship

a Defect!

Short Lead Time Continuous Improvement

GMS Executive Overview

$

Foster a culture of change and constant improvement

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 14

A Company-Wide Operating System based on Lean Business Principles

GMS

Like An Atom We Need A

ll The Pieces Working Together!!

GMS

“One Company” – One System

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 15

The 33 Elements Work Together

GMS

Like A Jigsaw Puzzle You Need All The Pieces So It Can Work

GMS

Vision

Shop Floor Management

People Involvement

Open Communication Process

Small Lot Packaging

Simple Process Flow

Values

Health and Safety Priority Manufacturing Process Validation ???? ??

Team Concept Product Quality Standards

Fixed Period Ordering System/ Order Parts

Management by TAKT TimeTAKT ???? Workplace Organization

Quality Feedback/ FeedForward Level Vehicle Order Schedule

Controlled External Transportation ??? ?? ??

Andon Concept Total Productive Maintenance

Quality System Management

Scheduled Shipping / Receiving

Business Plan Deployment

Internal Pull / Delivery

Supply Chain Management

Lean Design of Facilities, Equipment, Tooling and Layout

Continuous Improvement Process

Problem Solving

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 16

4

GMS CASE STUDY

General Motors North America:

GMS

Before GMS: 1996

SPQRC

GMS

After GMS:

2003

SPQRC

BUT!!!…Toyota still enjoys 8% net profit while GM is at 1.5%

GM needs to outperform Toyota by US$1,500 – $2,000 / unit…

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 17

4

GMS as an Enterprise-Wide System

GMS is a common operating methodology that can be used anywhere in the organisation

Engineering

GMS

Manufacturing

Purchasing & Suppliers

SPO

Powertrain

Avoid the ‘Silo Syndrome’

Take an Integrated Approach Link the Functional Groups Together Used in Manufacturing but Principles are Generic

GMS Executive Overview

GM Confidential Version Date 2004.8.12

J Hamalian

John S. Hamalian

Slide 18

A Common ?Language? and Company Culture throughout the entire Customer Chain

GMS

Lean Business Principles

Designers & Product Engineering After-Sales & Dealers

Production

Sales & Marketing

Purchasing & Suppliers

Buyers

“One Company” with Customer First

J Hamalian

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 19

What is a ?Factory??

A place where a repeatable process is conducted in which there are inputs, internal activity and outputs

GMS

New Vehicle Factory

New Advertisement Factory

Expense Report Processing Factory

Purchasing Order Process Factory

Service Center Factory

Who are ?Operators??

Anyone who works in a highly repeatable job and requires support to be effective

Paradigm Shift: We have to think of the work we all do in terms of a common process methodology 5 Everyone Can Use Lean Business Principles

J Hamalian

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 20

People Involvement

GMS

? People Involvement Elements

? ? ? ? ? ? ? ? Vision Values Health

& Safety Qualified People Teamwork People Involvement Open Communication Leadership Behavior (Shop Floor Management)

GMS

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 21

GMS

Fish Philosophy Video

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 22

GMS

Fish Philosophy Video Discussion

?

What GMS concepts did we see in the video? Discuss as an open forum

?

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 23

Fish Philosophy Video Discussion

Environment At The Fish Company Enables:

?People Involvement/Employee Enthusiasm

?Teamwork ?Low Absenteeism ?Job Rotation/Flexibility….

GMS

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 24

People Involvement Company

GMS

PEOPLE are our most important resource!!!

Fruit = Quality Product Branches = Processes & Tools (GMS Elements)

Trunk = People & Mindset

Roots = Culture, Values & Philosophy (GMS Principles)

Soil = Environment

Like a Tree, People Need Nurturing for Growth

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 25

Change In Thinking

TRADITIONAL

VIP #1

GMS

MODERN

TEAM MEMBER #1

Team Member

Directors

Team Leader Group Leader Mgr

Managers

Supervisors

Operators

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 26

Leadership Mind Change

TOP-DOWN LEADERSHIP STYLE

Direction Support

GMS

MODERN LEADERSHIP MINDSET

TWOWAY STREET

Direction Support

80%

20%

20%

80%

J Hamalian

Give Orders

GMS Executive Overview

GM Confidential Version Date 2004.8.12

Teach & Coach!!!

John S. Hamalian

Slide 27

Employee Mind Change

TRADITIONAL EXPECTATION ? Just Do What You Are Told To Do MODERN EXPECTATION ? Participate in Making Standardized Work

GMS

? Employee Enthusiasm Not Important

? Continuously Improve Job

? Involved in Problem Solving ? Involvement Brings Enthusiasm!

J Hamalian

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 28

GMS

People Involvement Company

Effective Communication ? Empowerment

? Trust

? Teamwork/ Cooperation

GMS Executive Overview

GM Confidential Version Date 2004.8.12

? Mutual Respect

John S. Hamalian

Slide 29

People Involvement

Health and Safety Priority

GMS

Vision/ Mission Values

Shop Floor Management

People Involvement

Open Communication Process

Small Lot Packaging

Simple Process Flow Andon Concept

Health and Safety Priority

Manufacturing Process Validation Management by TAKT Time Workplace Organization

Product Quality Standards

Team Concept Period Fixed Ordering System/ Order Parts Quality Feedback/ Feedforward

Controlled External Transportation

Total Productive Maintenance

Quality Scheduled System Shipping / Management Receiving

Business Plan Deployment

Internal Pull / Delivery

Level Vehicle Order Schedules

Continuous Improve

ment Lean Design of Facilities, Equipment, Process Supply Tooling and Layout Chain Management Problem Solving

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 30

Health and Safety

“We are committed to protecting the health and safety of each employee as the overriding priority of the Corporation”.

> Our goal is:

GMS

ZERO Incidents!!

Group Discussion:

What is an ?Incident? vs. an ?Accident??

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 31

Building a “Safety Culture”

The Stages of Safety Awareness

No Problem – He Can Still Work!

GMS

Stage 1: Unawareness of Hazards

Stage 2: Awareness But No Action to Prevent Injury

GM Confidential Version Date 2004.8.12

Stage 3: Injury But Still No Concern

GMS Executive Overview

John S. Hamalian

Slide 32

Building a “Safety Culture”

The Stages of Safety Awareness

SPQRC

GMS

Stage 4: Injury and Realisation of Impact to Person and Company

GMS Executive Overview

Stage 5: Awareness of Hazards & Proactive Countermeasures to Prevent Incidents

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 33

Heinrich Hazard Pyramid

Most Reactive

GMS

Employee Hits Head on Edge of Desk While Falling. Breaks Neck. Dies. Employee Fractures Arm While Hitting the Floor. Two Weeks Out of Work. While Falling, employee?s Body Grazes Edge of Metal Drawer and Lacerates Arm. Requires Four Stitches Employee Slips on Coffee Employee Spills Coffee on Floor and Walks Away

1

Fatality

Lost Workday Injury

300

Reactive

Recordable or First Aid Injury

3,000

Proactive

Near Miss

30,000

Most Proactive

Potential Hazard / Unsafe Situation

Herbert Heinrich Travelers Insurance Co.

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 34

Health and Safety

? How

GMS

Can We Achieve Our Goal of zero First Aid Injuries, Recordables or Lost Work Days?

- Incident Prevention (Building a Safety “Culture”)

- Incident Reporting, Tracking and Resolution (encourage honest, open reporting to enable Problem Solving & avoid repeat incident)

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 35

GMS

Health and Safety

Incidents can be Prevented through these five activities and more:

?

?

? ?

?

Behavior Workplace Organization/5S Personal Protective Equipment Safe Use of Hazardous Materials Ergonomics

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 36

People Involvement

Team Concept

GMS

Vision/ Mission Values

Shop Floor Management

People Involvement

Open Communication Process

Small Lot Packaging

Simple Process Flow Andon Concept

Health and Safety Priority

Manufacturing Process Validation Management by TAKT Time Workplace Organization

Product Quality Standards

Team Concept Period Fixed Ordering System/ Order Parts Quality Feedback/ Feedforward

Controlled External Transportation

Total Pro

ductive Maintenance

Quality Scheduled System Shipping / Management Receiving

Business Plan Deployment

Internal Pull / Delivery

Level Vehicle Order Schedules

Continuous Supply Lean Design of Facilities, Equipment, Improvement Chain Tooling and Layout Process Management Problem Solving

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 37

Teamwork

GMS

What is a Team?

Group Discussion:

HOW DO YOU ACHIEVE REAL TEAMWORK?

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 38

Team Concept

GMS

Small groups of empowered people who share common goals and support each other through common tasks

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 39

Team Concept

GMS

Team Member

The Organization Structure Is Designed To Support Small, Empowered Teams

Team Leader Group Leader & Support Areas

Leadership

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 40

Team Concept

?

GMS

Common SPQRC goals and regular team meetings. Empowerment to make decisions within spans of control Responsibility for: – Making Standardized Work – Problem Solving – Continuous Improvement

?

?

?

Job Rotation is generally performed

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 41

A Single Team Can Only Be Successful If The Big Team Wins!!…

Individual Family

GMS

Quality Purchasing Design

Human Resources Engineering Unions PC&L Finance Suppliers

Company

Manufacturing Information Systems

Sales & Marketing

Nation & World

J Hamalian

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 42

People Involvement

GMS

Vision/ Mission Values

Shop Floor Management

People Involvement

Open Communication Process

Small Lot Packaging

Simple Process Flow

Health and Safety Priority Manufacturing Process Validation Management by TAKT Time

Team Concept Product Quality Standards

Fixed Period Ordering System/ Order Parts

Controlled External Transportation

Andon Concept Total Productive Maintenance

Quality Feedback/ Feedforward Level Vehicle Order Schedule s

Quality System Management

Scheduled Shipping / Receiving

Business Plan Deployment

Workplace Organization

Internal Pull / Delivery

Supply Chain Management

Lean Design of Facilities, Equipment, Tooling and Layout

Continuous Improvement Process

Problem Solving

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 43

Qualified People

Our People Will Be. . .

? ? ? ? ?

GMS

Empowered/Engaged/Energetic Knowledgeable Flexible/Open-Minded Customer Oriented Skilled in the Continuous Improvement Process and Problem Solving Able to Work in Teams

GM Confidential Version Date 2004.8.12

?

GMS Executive Overview

John S. Hamalian

Slide 44

GMS

Qualified People

Job Improvement & Growth

People Development

Job Performance Fee

dback

Training

Hiring/ Assessment

Time

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 45

GMS

WE LEARN

10% of what we read 20% of what we hear 30% of what we see 50% of what we see and hear 70% of what we discuss with others 80% of what we experience personally 95% of what we teach to someone else

William Glasser

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 46

Training Methodology

JOB INSTRUCTION TRAINING (JIT)

GMS

The Four Steps of JIT

Confirmation Awareness

Step 4: FOLLOW UP

(Trainee Confirm Skill)

A

P

Step 1: PREPARE TRAINEE

(Study Standardized Work)

HEAR SEE DO

Step 3: TRY OUT PERFORMANCE

(Trainee Do, Trainer Watch) Skill

Why – What – How!!!

C

D

Step 2: PRESENT OPERATION

(Trainer Do, Trainee Watch) Knowledge

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 47

People Involvement

People Involvement

GMS

Vision/ Mission Values

Shop Floor Management

People Involvement

Open Communication Process

Small Lot Packaging

Simple Process Flow

Andon Concept

Health and Safety Priority

Manufacturing Process Validation Management by TAKT Time Workplace Organization

Product Quality Standards

Team Concept Period Fixed Ordering System/ Order Parts Quality Feedback/ Feedforward

Controlled External Transportation

Total Productive Maintenance

Quality Scheduled System Shipping / Management Receiving

Business Plan Deployment

Internal Pull / Delivery

Level Vehicle Order Schedules

Continuous Supply Lean Design of Facilities, Equipment, Improvement Chain Tooling and Layout Process Management Problem Solving

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 48

People Involvement Element (Involvement & Recognition)

Create and maintain an environment which fosters a “spirit of pride”

GMS

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 49

Involvement & Recognition

There are three aspects of Involvement & Recognition:

GMS

1. Individual & Team Ideas 2. Small Group Programs 3. Rewards and Recognition

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 50

People Involvement

Open Communication Process

GMS

Vision/ Mission Values

Shop Floor Management

People Involvement

Open Communication Process

Small Lot Packaging

Simple Process Flow

Andon Concept

Health and Safety Priority

Manufacturing Process Validation Management by TAKT Time Workplace Organization

Product Quality Standards

Team Concept Period Fixed Ordering System/ Order Parts Quality Feedback/ Feedforward

Controlled External Transportation

Total Productive Maintenance

Quality Scheduled System Shipping / Management Receiving

Business Plan Deployment

Internal Pull / Delivery

Level Vehicle Order Schedules

Continuous Supply Lean Design of Facilities, Equipment, Improvement Chain Tooling and Layout Process Management Probl

em Solving

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 51

GMS

Open Communication Process

? Leaders must drive communications ? Actively engage employees in the business openly & frequently ? Open-Door Policy ? Listen Often ? Have a Physical Presence (MBWA – Management By Walking Around)

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 52

Guiding Principles

WHAT - HOW - WHY? Traditionally, communication only focuses on the “WHAT” and maybe the “HOW”, but people deserve to know the “WHY”!!!

GMS

EVEN IF THEY DON’T AGREE AT LEAST THEY WILL UNDERSTAND!!!

J Hamalian

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 53

Key Enablers

Effective Use Of Media

BEST!!

Core Level Face-to-face Communication

Communication Boards Satellite Broadcasts State of the Business Mtg. Team Mtg. Internet / Intranet Job Postings

GMS

BETTER

Level One Face-to-many faces Communication

Group Training

Teaching Coaching Training Feedback

Business Update Mtg.

Team Boards

Dept. Head?s. Mtg. Diagonal Slice Mtg. E-mail

GOOD

Newsletters

Make a Communication Plan!

GMS Executive Overview

Voice Mail

Level Two Informational Communication

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 54

People Involvement

Shop Floor Management

GMS

Vision/ Mission Values

Shop Floor Management

People Involvement

Open Communication Process

Small Lot Packaging

Simple Process Flow

Health and Safety Priority

Manufacturing Process Validation Management by TAKT Time Workplace Organization

Product Quality Standards

Team Concept Period Fixed Ordering System/ Order Parts Quality Feedback/ Feedforward

Controlled External Transportation

Andon Concept

Total Productive Maintenance

Quality Scheduled System Shipping / Management Receiving

Business Plan Deployment

Internal Pull / Delivery

Level Vehicle Order Schedules

Continuous Supply Lean Design of Facilities, Equipment, Improvement Chain Tooling and Layout Process Management Problem Solving

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 55

Leadership Behavior

(Shop Floor Management)

GMS

Go and See Leadership Style Lead By Example SPQRC-based Meeting Structure Proactive Communication Process Regular Checks of Processes

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 56

Go and See Leadership Style

GMS

The focus of leadership is on the places where work is performed. This is accomplished through the “Go and See” philosophy:

Go and See the work areas where concerns exist and to check progress

“Don?t just sit at your desk, go and see what is happening!!!”

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 57

Lead By Example

For Example – If You Want People to Keep Their Area Clean, You Had Better Also Keep YOUR Area Clean!!!

GMS

Leader

J Hamalian

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 58

GMS

I Love Lucy Video Part I

(Stop video before Chocolate Assembly Line)

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 59

GMS

I Love Lucy Video Discussion

?

What GMS concepts did we (not) see in the video? (at home and at the job!) Discuss as an open forum – not by teams

?

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 60

I Love Lucy Video Discussion

What did we see in the video:

?Lack of Teamwork: ? At home, spouses did not understand each other?s jobs ? No teamwork at factory

GMS

? Boss was traditional top-down style, not a leader

?Lack Of Qualified People: ? Job qualifications not clear, poor screening process ? Lucy & Ethel not qualified for job ? Lucy & Ethel received poor training by boss

?Lack of Open Communication:

? Spouses did not communicate enough (example – at breakfast) ? No talking at factory results in no support & no teamwork

GMS Executive Overview

GM Confidential Version Date 2004.8.12

J Hamalian

John S. Hamalian

Slide 61

GMS

Vision

Shop Floor Management

Values

Health and Safety Priority Manufacturing Process Validation Management by TAKT Time

WASTE

Team Concept Product Quality Standards Fixed Period Ordering System/ Order Parts Quality Feedback/ Feedforward Level Vehicle Order Schedul es Quality System Management Scheduled Shipping / Receiving Internal Pull / Delivery Supply Chain Management

People Involvement

Open Communication Process

Small Lot Packaging

Simple Process Flow Andon Concept Total Productive Maintenance

Controlled External Transportation

Business Plan Deployment

Workplace Organization

Lean Design of Facilities, Equipment, Tooling and Layout

Continuous Improvement Process

Problem Solving

Vision

Shop Floor Management

People Involvement

Open Communication Process

Small Lot Packaging

Simple Process Flow

Values Health and Safety Priority Manufacturing Process Validation Product Quality Standards Team Concept

Fixed Period Ordering System/ Order Parts

Controlled External Transportation

Andon Concept

Quality Feedback/ Feedforward

Quality System Management

Management by TAKT Time Internal Pull / Delivery Level Vehicl e Order Sche dules

Scheduled Shipping / Receiving

Business Plan Deployment

Total Productive Maintenance

Workplace Organization

Supply Chain Management

Lean Design of Facilities, Equipment, Tooling and Layout

Continuous Improvement Process

Problem Solving

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 62

GMS

How Often Do We See These Scenarios in Our Work Area?

Stocking Up Inventory

Excess Walking

Equipment Breakdown

Excessive Transporting, Storage & Handling

Decision Communication and Reporting Maze

Meetings, Meetings, Meetings!

GMS Executive Overview

GM Confidential Version D

ate 2004.8.12

John S. Hamalian

Slide 63

GMS

Enemies of Any Process

Three Enemies:

7 Wastes

(Muda), Unevenness (Mura), and Overburden (Muri)

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 64

7 TYPES OF WASTE

Sending back forms for incomplete or inaccurate data CURRENT Processing excessive written THINKING communication to determine Shift issues requiring attention (mental processing)

Mindset

Producing reports that are not GMS used, performing more analysis than required, producing reports before they REQUIRED needed are THINKING

Correction

Processing

P

C

WASTE

Keeping multiple copies of reports

Inventory

Over Production

I

W

Waiting

TYPES OF WASTE

O M

Motion

M

Material Movement

Delays in getting needed information, approvals, or decisions

Searching for misplaced items

WASTE NOT DEFINED WASTE IS "TANGIBLE" Filing documents that will REACT TO LARGE EXAMPLES IDENTIFY never be used again MANY SMALL OPPORTUNITIES REACTIVE IMPROVEMENT LEADS TO LARGE OVERALL CHANGE CONTINUOUS IMPROVEMENT

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 65

GMS

Waste is EVERYWHERE!!!

Waste Elimination through People Involvement is the Foundation of the entire Operating System

J Hamalian

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 66

Make Waste Visible & Conquer It!

GMS

There are two major categories of waste: 1. Obvious waste 2. Hidden waste.

Most Waste is Hidden

Waste is easy to identify in a well organised organisation

J Hamalian

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 67

Why Eliminate Waste?

Poor companies let waste slowly build up then realize they are in trouble and make huge cuts that affect value-added activities and people?s livelihood. Successful companies continuously eliminate waste From all processes and actually GROW the company!!

GMS

Example: Toyota

J Hamalian

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 68

GMS

Eliminating Waste Is Job Security

WASTE

$

MORE MONEY FOR VALUEADDED THINGS BETTER PRODUCTS, BETTER FEATURES, MORE ADVERTISING

INCREASED SALES, INCREASED DEMAND, MORE PRODUCTION, MORE JOBS

J Hamalian

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 69

Standardization

GMS

?

Standardization Elements

Standardized Work Workplace Organization Management By Takt Time Visual Management

? ? ? ?

GMS

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 70

Standardization

The purpose of standardization is to reduce variation and stabilize, so as to achieve a base from which to grow and improve.

World Class

GMS

Change

“THE WEDGE” TO STABILIZE BEST PRACTICE

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 71

Standardization

A Standard Is The Best Current Practic

e Based On Many People?s Experience & Lessons Learned, so…

GMS

DON’T SHORTCUT THE STANDARD!!!

BAD THINGS COULD HAPPEN, ESPECIALLY SAFETY & QUALITY PROBLEMS

Standard

IF YOU DON’T LIKE THE STANDARD, TRY TO CHANGE IT, BUT NEVER SHORTCUT IT….

J Hamalian

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 72

GMS

What Happens When We Do Not Follow Standards???

EVERY YEAR PEOPLE DIE FROM NOT FOLLOWING LOCK-OUT PROCEDURE

U.S SUBMARINE HITS JAPANESE FISHING BOAT SURFACING PROCEDURE NOT FOLLOWED

GERMAN PLANE CRASHES IN SWITZERLAND – AIR TRAFFIC CONTROL PROCEDURES IGNORED

EXXON VALDEZ OIL SPILL – CAPTAIN DID NOT FOLLOW STANDARDS

J Hamalian

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 73

GMS

MAKE RULE

TEACH RULE KEEP RULE

It is easy to make standards, but we do not always do a good job communicating them and are even worse at sustaining them (including ourselves)

If you do not have a process to sustain a standard – why even introduce it in the first place?

J Hamalian

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 74

People Involvement Link to Standardization

■ Results achieved only when people all do the right thing

GMS

Lack of Discipline results in Chaos

GMS Executive Overview

Discipline and Orderly Environment

I.S. Han - RBPS

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 75

Standardization

Workplace Organization

Shop Floor Vision/ Management Mission Health and Safety Priority

GMS

People Involvement

Open Communication Process

Small Lot Packaging

Values

Simple Process Flow Andon Concept

Team Concept Period Fixed Ordering Controlled System/ External Order Parts Transportation Scheduled Quality Shipping / System Receiving Management

Manufacturing Process Validation Management by TAKT Time

Product Quality Standards

Total Productive Maintenance

Quality Feedback/ Feedforward

Business Plan Deployment

Workplace Organization

Internal Pull / Level Vehicle Delivery Order Schedules

Lean Design of Facilities, Supply Equipment, Chain Tooling and Layout Management

Continuous Improvement Process

Problem Solving

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 76

GMS

WPO Motto: “A place for everything and everything in its place”

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 77

Workplace Organization

Put order to the workplace by making Standards that allow “out-of-standard” conditions to be visible!!

GMS

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 78

GMS

How is workplace organization done?

Workplace Organization

5S

1 Sift/Clear

GMS Executive Overview

5 Self Discipline/ Cont. Improvement

4 Sustain/Maintain 3 Sweep/Clean 2 Sort/Standardize

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 79

GMS

Why workplace organiz

ation?

WPO is a key means of visualizing and eliminating waste

Anything outside the standard is WASTE!!!

Make Waste Visible!!!

GMS Executive Overview

GM Confidential Version Date 2004.8.12

J Hamalian

John S. Hamalian

Slide 80

GMS

Why workplace organization?

SAFETY

Good 5S Leads to Good Safety! trip, slip hazards, etc.

No

QUALITY

Items always in same place means less likely to make mistakes

COST

Items always in same place means less wasteful and more repeatable motions

J Hamalian

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 81

Example of 5S

Which Cabinet Do You Want?

GMS

(Which one is Safer, makes Waste visible, leads to less Mistakes and lets you get parts Quicker?)

Cabinet “Before 5S”

Cabinet “After 5S”

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 82

Standardization

Management by TAKT Time

GMS

Vision/ Mission

Shop Floor Management

People Involvement

Values

Health and Safety Priority

Open Communication Process Team Concept

Small Lot Packaging

Simple Process Flow

Fixed Period Controlled Ordering External System/ Transportation Order Parts

Andon Concept

Manufacturing Process Validation Management by TAKT WorkTime place Organization

Product Quality Standards

Quality Feedback/ Feedforward

Quality Scheduled System Shipping / Management Receiving Lean Design of Facilities, Supply Equipment, Chain Tooling and Layout Management

Total Productive Maintenance

Business Plan Deployment Continuous Improvement Process

Internal Pull / Delivery

Level Vehicle Order Schedules

Problem Solving

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 83

Time Management Philosophy

GMS

Instilling A Sense Of Time & Discipline to Keep It

No Time Management: No Agenda 1) Meeting Time 2) Meeting Place 3) Participants (Leader has no regard for time)

? No Sense of Time Built in Process ? Some arrive late, others have to wait ?No ?timekeeper? to keep discipline ? Meeting can easily go over time thus producing waste

GMS Executive Overview

Management By Takt: Agenda with Time 8:00 Introductions 8:10 Kick-off 8:30 Team Activity 11:00 Report-Outs

(Leader Keeps Time)

? Sense of Time Built In to the process ? All members have a Respect for time ? Leaders ensure Discipline ? Keeping time minimizes Waste

J Hamalian

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 84

Management By Takt Time (Time Management)

Takt Time: – The Required Amount Of Time To Produce a Product Or Service Based On Customer Demand

Takt Time =

Operational Time Per Period Number of goods or services required per time period

GMS

Relate all Work to Time and Make it Visual and Manageable!

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 85

Management By Takt Time (Time Management)

Operation

Take-Off

GMS

Example: Airliner

60’

Flight Attendant has 60’ to s

erve drinks – if there are 60 passengers, Takt Time = 1’)

30’

Serve Drinks

90’

Landing

Meeting

Kick-Off

Example: Board Meeting

8 Hours

Quarter Review

Lunch

Next Steps

Wrap-Up

Project

Concept

Example: Marketing

3 months

Approval

Production Ready

GM Confidential Version Date 2004.8.12

Advertisement shown on T.V.

J Hamalian

GMS Executive Overview

John S. Hamalian

Slide 86

Standardization

GMS

Vision/ Mission

Shop Floor Management

People Involvement

Open Communication Process

Small Lot Packaging

Values

Health and Safety Priority

Fixed Period Team Concept Ordering System/ Order Parts

Simple Process Flow Controlled External Transportation

Andon Concept

Manufacturing Process Validation

Product Quality Standards

Quality Feedback/ Feedforward

Quality System Management

Total Productive Maintenance

Management by TAKT Time Workplace Organization

Scheduled Shipping / Receiving

Business Plan Deployment

Internal Pull / Delivery

Level Vehicle Order Schedules

Supply Chain Management

Lean Design of Facilities, Equipment, Tooling and Layout

Continuous Improvement Process

Problem Solving

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 87

GMS

Visual Management Key Concepts

MAKE STANDARD & OUT OF STANDARD CONDITIONS CLEAR & VISIBLE!

GMS Executive Overview

GM Confidential Version Date 2004.8.12

x

x

J Hamalian

John S. Hamalian

Slide 88

GMS

Visual Management Key Concepts

STATUS AT A GLANCE

GUIDELINE – SHOULD NOT TAKE MORE THAN ONE SECOND TO GRASP ANY SITUATION!

J Hamalian

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 89

GMS

“A Picture Is Worth A Thousand Words.”

Get Standards Out From the Desk and Into the Open!

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 90

Example

GMS

Which visual method communicates information (how much time is left for walking) better?

Stack Light

WALK DON?T WALK

J Hamalian

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 91

GMS

Standardization

Vision/ Mission

Shop Floor Management Health and Safety Priority

People Involvement

Open Communication Process

Small Lot Packaging

Values

Simple Process Flow Controlled External Transportation Andon Concept

Team Concept Period Fixed Ordering System/ Order Parts Quality Quality System Feedback/ Management Feedforward Level Vehicle Order Schedules

Manufacturing Process Validation Management by TAKT Time Workplace Organization

Product Quality Standards

Total Productive Maintenance

Scheduled Shipping / Receiving

Business Plan Deployment

Internal Pull / Delivery

Supply Lean Design of Facilities, Chain Equipment, Management Tooling and Layout

Continuous Improvement Process

Problem Solving

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 92

Standardized Work

The documented, current best method to Safely and

Efficiently perform any repeatable process that meets the necessary level of Quality

GMS

Production

Office

Standardized Work Can Be Performed Everywhere!!!

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 93

GMS

Standardized Work

Without Standardization

With Standardization

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 94

GMS

Each Individual Has Good Ideas – If We Do Not Document The Best Methods Then We Are Not Fully Utilizing The Team?s Brainpower and We Will Never Improve Or We May Actually Get Worse!!!

Without Standardized Work We Are Destined To Repeat The Same Mistakes Over and Over Again!

J Hamalian

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 95

GMS

Would You Want To Get Into A Plane Where The Crew Did Not Exactly Follow A Standardized Check Process??? – Even Though They Have Performed It Hundreds Of Times!!! 1. Check Fuel 2. Check Tires 3. Check Instruments

Nobody’s Memory is Perfect - Have the Discipline to follow Standardized Work. Don’t Get Complacent!

GMS Executive Overview

GM Confidential Version Date 2004.8.12

J Hamalian

John S. Hamalian

Slide 96

GMS

Lego Exercise

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 97

Built-In-Quality

GMS

?

Built-In Quality Key Elements

Customer Quality Standards Process Validation/Change Control In-Process Control Feedback/Feedforward Communication

? ? ? ?

GMS

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 98

Built-In-Quality

GMS

?

What Is Quality? Group Discussion

?

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 99

Definitions

GMS

?

Quality is what the customer perceives to be acceptable to achieve his/her enthusiasm

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 100

Poor Quality Means Lost Sales

GMS

Mad Cow

Firestone

uninstalled shift lock (Sudden Acceleration)

(Unintended Accidents)

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 101

Built-In-Quality

? What is Built-In-Quality?

? Group Discussion

GMS

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 102

What is Built-In Quality?

Understand Your Supplier and Customer and build quality INTO the process through Prevention, Detection and Containment so defects are not passed to the customer!

GMS

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 103

The Customer Chain Satisfy Your Customer…

Design & Engineering Production Sales & Marketing

GMS

Dealers

Suppliers Buyers

Every Process Has at Least One “Customer” and One “Supplier”

Who is Your Customer?

Who is Your Supplier?

- Group Discussion

GM Confidential Version Date 2004.8.12

GMS Executive Overview

John S. Hamalian

Slide 104

Built-In-Quality Motto

Satisfy Your Customer…

GMS

Do not

Accept Build Ship

a Defect!

Solve Problems Through Teamwork!

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 105

Don’t run away from the problem!

What water leaks? I don?t see any water leaks

This car wasn?t made on my shift

I won?t run any trial until I have an assembly method from Engineering and the manpower. The problem is Press Shop. The flange is too long.

GMS

It is not from my area, maybe it?s the sealer

The problem is that the pieces are bad from the supplier.

Quality Through Teamwork – Know Your Customer!

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 106

Always Remember The Priorities…

GMS

Customer Enthusiasm! Safety People Quality Responsiveness Cost Quality is the Key to Our Survival – We Will Not Maintain Global Auto Leadership without it and it Involves Each and Every One of Us, Day in and Day Out

J Hamalian

Importance

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 107

GMS

Feedback/Feedforward

Process A

Process B

Process C

“Suppliers”

You

“Customer”

Reactive

Proactive

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 108

GMS

I Love Lucy Video Part II

(Start video at Chocolate Assembly Line)

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 109

I Love Lucy Video Discussion

What did we see in the video:

? Lack of Standardized Work: ? No documented standardized work on job ? No standardized work to use as basis for training

GMS

? No quality standard for completed chocolate

? Lack Of Management By Takt Time: ? Takt Time arbitrarily changed ? No communication or planning of Takt Time change ? No visual indication of workstation beginning and end

? Lack of Built-In Quality:

? No way to call for help ? No way to stop line or prevent defects from leaving station

GMS Executive Overview

GM Confidential Version Date 2004.8.12

J Hamalian

John S. Hamalian

Slide 110

Short Lead Time

GMS

? Short Lead Time Key Elements ? Simple Process Flow ? Pull System Concept ? Level Scheduling

GMS

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 111

Short Lead Time

GMS

The Relentless Pursuit to Reduce the Amount Of Time To Produce a Product Or Service

Achieve Customer Enthusiasm by delivering more quickly and reducing costs, while maintaining quality

J Hamalian

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 112

GMS

Philosophy

Process Thinking at Toyota

“Brilliant process management is our strategy” “We get brilliant results from average people managing brilliant processes”

Toyota Observes that…

“… our competitors often get average (or worse) results from brilliant people managing b

roken processes.”

James Womack

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 113

Short Lead Time

Guiding Principles Simple Process Flow “The Perfect Process”

GMS

“Simple Sequential Process Flow of Material and Information”

? Identify Customer Requirements ? Relate Work to Time ? Make Process Flow & Waste Visual ? Use First In First Out (FIFO) ? Pull from Customer, not Push from Supplier ? Establish Rhythm (level scheduling) in Small Lots ? Make Progress/Delays Visual

One Key Tool is “Value Stream Mapping”

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 114

Understanding the flow determines where to apply Process Improvements

GMS

Flow

Flow Restrictors

Theory of Constraints

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 115

Value Stream Mapping

What is a Value Stream?

A value stream involves all the steps, both value added and non value added, required to complete a product or service from beginning to end

GMS

What is a Value Stream Map?

A value stream map follows a product?s production path from beginning to end, and provides a visual representation of every process in both the material and information flows.

Make The Process Visual!

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 116

Value Stream Maps Enable a System View

Scoping the Value Stream

GMS

Determine the Value Stream to be improved Understanding how things currently operate. This is the foundation for the future state.

Current state drawing

Future state drawing

Designing a lean flow through the application of GMS principles

The goal of mapping!

Planning and Implementation

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 117

Jack?s Taxes - Current State

Client

40 clients

GMS

Send reminder

IN

Sort receipts & documents

Prepare worksheet

Confirm deductions

IN Jack P/T 30 min W/T --FTQ 10%

3 weeks

TS

IN

3 days

Print & Collate TS forms

Review & sign forms

Mail forms

IN

3 days

IN

1 day

1 week

John P/T 10 min W/T --FTQ 100%

Jack P/T 60 min W/T 1 week FTQ 95%

Jack P/T 10 min W/T 1 week FTQ 50%

John P/T 15 min W/T --FTQ 98%

Jack P/T 15 min W/T --FTQ 100%

John P/T 10 min W/T --FTQ 100%

P/T W/T FTQ

10 min 100 %

30 1 week min 10 %

3 weeks

60 min 1 week 95 %

10 min 1 week 50 %

3 days

15 min 98 %

3 days

15 min 100 %

1 day

10 min 100 %

140 min 7 wks, 2 days 4.7 %

Total Lead Time:

GMS Executive Overview

GM Confidential Version Date 2004.8.12

7 wks, 2 days, 140 min

Slide 118

John S. Hamalian

Jack?s Taxes – Process Improvement

Client

40 clients

? Customer ? Work

requirements? flow smoothly? GMS ? Trigger & sequence work? ? Rhythm (leveling)? ? Progress & delays visible? ? Process improvements?

Takt Time = Available time / Customer Requirements

= 40 days / 40 Clients = 1 per day

Stand. Work

S

end reminder Sort XOXO receipts & documents Prepare worksheet TS Confirm deductions Print & Collate TS forms

FIFO

Review & sign forms

Mail forms

IN

IN Jack P/T 30 min Data entry W/T --Worksheet FTQ 10% training

3 weeks

IN

IN

3 days

IN

1 day

1 week

COMBINE PROCESSES 3 days

John P/T 10 min W/T --FTQ 100%

P/T W/T FTQ

10 min 100 %

30 1 week min 10 %

min 3 Individual weeks 1 week

Jack John Jack John P/T 60 min P/T 10 min P/T 15 min W/T 1 week W/T 1 week W/T --FTQ 95% FTQ 50% FTQ 98% Reduce process time to 75 min Standardize Work 15 60 10

min 1 week 50 % 3 days min 98 %

Jack P/T 15 min W/T --FTQ 100%

John P/T 10 min W/T --FTQ 100%

3 days

15 min 100 %

1 day

10 min 100 %

140 min 7 wks, 2 days 4.7 %

1040, 1040EZ 95 % training

Total Lead Time: 7 wks, 2 days, 140 min

GM Confidential Version Date 2004.8.12

GMS Executive Overview

John S. Hamalian

Slide 119

Customer Requirements:

?Tax Forms completed accurately ?Finished before filling time ?Lowest possible cost

Jack?s Taxes Future State

Client

40 clients 1 per day Over 8 weeks

GMS

Takt Time = Available time / Customer Requirements = 40 days / 40 Clients = 1 per day

max 1 day Send Reminder IN John P/T 10 min

W/T FTQ 100%

P/T W/T FTQ 10 min

max 1 day Check & sign forms IN Jack P/T 15 min W/T 1 day FTQ 100%

15 min

XOXO

Data entry + print FS forms John P/T 75 min

W/T FTQ 98%

75 min

FIFO

Mail forms

John P/T 10 min W/T 1 day FTQ 100%

10 min 1 day 100 min 2 days

1 day

100 %

98 %

100 %

100 %

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

98 % 2 days, 100 min

Slide 120

3 Areas of Short Lead Time

Total Lead Time (Order To Delivery)

Receive Order To Delivery of Product and Receive Payment (O.T.D.)

GMS

Process Lead Time (Lean Materials) Product Lead Time

From Raw Material to Final Assembly

Reduce Lead Time to Produce Any Good Or Service

Examples: ? Product Development (Concept to SOP) ? Budget Development ? Marketing Clinic Feedback

J Hamalian

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 121

Continuous Improvement

GMS

? Continuous Improvement Key Elements

? ? ? ? Business Plan Deployment Problem Solving Andon Concept Continuous Improvement Process

GMS

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 122

Continuous Improvement Company

No Company Today Can Survive Without Having All Employees Focused on Continuous Improvement

GMS

Small, steady improvements to constantly improve The Standard!!

J Hamalian

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 123

Build a Continuous Improvement Culture

Poor Organisations Resist Change and Become Stifled and Stale – Great Organisations Embrace Change and Constantly Look for Ways to Improve

GMS

”The Only Constant is Change”

Never Be Satisfied With The ?Status Quo?!

J Hamalian

GMS Executive Overview

GM Confidential Version Date

2004.8.12

John S. Hamalian

Slide 124

Continuous Improvement

GMS

Standardized Work Is A Baseline for Many, Small Continuous Improvements!!!

Improvement Improvement

Improvement

Standardization Standardization

Standardization

Standardization

Once the Improvement is Validated, Update the Standard!

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 125

The PDCA Cycle

PDCA is a Fundamental Concept Throughout GMS

GMS

Grasp the Situation

Plan

Action

Do

Check

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 126

The PDCA Cycle is One Of The Most Important Concepts In A Company

Poor companies do little planning, mostly doing, do not check their status and then react to everything…

GMS

P

D

REACT

Or, they do a lot of Planning and no Execution or check system which again leads to Reaction or lack of Improvement…

? ?

J Hamalian

P

D

REACT

World-Class companies do excellent planning, always perform checks that enable taking corrective action and stay on schedule…

P

D

C

A

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 127

PDCA Can Be Used For Anything

Our Family Has Not Had A Vacation In A Long Time!

GMS

Grasp the Situation

Let?s go to the Beach!!!

Plan

Fix oil leak & leave on time Prepare for the trip

Action

Two days before leaving, check engine – OIL LEAK!

Do

Check

J Hamalian

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 128

GMS

Continuous Improvement

Business Plan Deployment

Vision

Shop Floor Management

People Involvement

Open Communication Process Team Concept

Small Lot Packaging

Values

Health and Safety Priority Manufacturing Process Validation Management by TAKT Time Workplace Organization Internal Pull / Delivery In-Process Control and Verification

Simple Process Flow Andon Concept

Quality Feedback/ Feedforward

Fixed Period Ordering System/ Order Parts Quality System Management

Controlled External Transportation

Scheduled Shipping / Receiving

Total Productive Maintenance

Business Plan Deployment

Level Vehicle Order Schedules

Supply Chain Management

Lean Design of Facilities, Equipment, Tooling and Layout

Continuous Improvement Process

Problem Solving

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 129

Before BPD…

? ? ?

Leader

GMS

?

no ownership

ONLY (S)HE KNOWS THE GOALS…

?

?

no regular reviews

GM Confidential Version Date 2004.8.12

GMS Executive Overview

John S. Hamalian

Slide 130

After BPD…

GMS

REGULAR COMMUNICATION

CLEAR TARGETS

VISION

TRACK PERFORMANCE

Leader

DEPLOY RESOURCES

EVERYONE KNOWS THE GOALS…

GM Confidential Version Date 2004.8.12

COMMON GOALS

CLEAR DIRECTION

GMS Executive Overview John S. Hamalian

GME-BPD Guide

Slide 131

Achieving Our Vision

In order for GM to achieve Its VISION, we have to achieve our Goals…

GMS

Vision/ Mission

Concr

ete GOALS (SPQRC)

SPECIFIC OBJECTIVES

CLEAR & MEASURABLE TARGETS A METHOD TO RESEARCH THE TARGETS

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 132

Who is involved in BPD? – Everyone!!!

Why Engage the Workforce?

Why? Why?

% of People Involvement

GMS

Why? Why?

Why?

50% 40% 30% 20% 10%

1-6 6-10 10-20 20-40 40-100

% of Possible Improvement

No ?One Person? Has All the Best Ideas!!!

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 133

The Cascading Process

Level 4 Team ? Clear Targets ? Review Process

GMS

Level 3 Group Leader ? Action Plans ? Clear Targets ? Review Process

Level 2

Department Manager

Level 1 Top Leadership ? Mission/Strategy ? Goals & Objectives ? Clear Targets ? Action Plans ? Review Process

? Goals & Objectives ? Clear Targets ? Action Plans ? Review Process

Each Level of Leadership Must Hand Down Simple & Clear Targets to Their Team…

Go Down To The Lowest Level!!!

S.M.A.R.T. Targets: Specific, Measurable, Aligned, Realistic & Timed

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 134

GMS

If You Can?t Measure It, You Can?t Manage It If You Can?t Manage It, You Can?t Improve It

Targets and Metrics Measuring May Seem Like Extra Work and Too Controlling, but How Else Can You Get a Baseline for Improvement?

J Hamalian

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 135

PDCA is the foundation of BPD

PLAN

Annual Business Plan Actions

GMS

100 50

Goals, Objectives, Targets, Methods

DO

Countermeasures

Activities

PROBLEM SOLVING

Regular Reviews

X

Below Expectations Needs Improvement

ACT

GMS Executive Overview

? Open, Team Discussion ? Coaching & Learning ? Get Support & Resources ? Go To See

Meets Expectation

CHECK

John S. Hamalian

Slide 136

GM Confidential Version Date 2004.8.12

3rd

1st

0

GMS

Continuous Improvement

Andon Concept

Vision/ Mission

Shop Floor Management

People Involvement

Open Communication Process

Small Lot Packaging

Values

Health and Safety Priority

Team Concept In-Process Control and Verification

Fixed Period Ordering System/ Order Parts

Simple Process Flow Controlled External Transportation Andon Concept

Manufacturing Process Validation Management by TAKT Time

Quality Feedback/ Feedforward

Quality System Management

Scheduled Shipping / Receiving

Total Productive Maintenance

Business Plan Deployment

Workplace Organization

Internal Pull / Delivery

Level Vehicle Order Schedules

Supply Continuous Lean Design of Facilities, Equipment, Chain Improvement Tooling and Layout Management Process

Problem Solving

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 137

What is the Andon Concept?

GMS

? The ANDON Concept encourages employees to call for help when there is a problem or out of standard situation, using audio and/or

visual signals to help attract attention ? The ANDON Concept is an enabler to control quality while keeping the process going by pulling in support to address issues before they become problems

Quality Andon System

Hotel “Bell” for Bellhop

Walkie Talkie/Mobile Phone

Airplane Call for Attendant

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 138

Always Remember The Priorities…

GMS

Safety People Quality Responsiveness Cost

Importance

For Example, Sometimes We Have To Sacrifice Quantity to Achieve Quality

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 139

Function of Everyone including Managers and Staff is to Support our Team Members

GMS

Needs help

Team Member

Pull Andon

Team Leader

Support

Decision

Group Leader

Support

Decision

Mgr

Support

Decision

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 140

GMS

Andon Is Not Just a System Of Wires and Lights

It is a Concept of Calling For Help Before It is Too Late

EVERYONE HAS AN “ANDON CORD”

Pull Your Andon!!!

J Hamalian

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 141

GMS

Continuous Improvement

Problem Solving

Vision/ Mission

Shop Floor Management

People Involvement

Open Communication Process

Small Lot Packaging

Values

Simple Process Flow Andon Concept

Health and Safety Priority Product Quality Standards

Manufacturing Process Validation Management by TAKT Time Workplace Organization

Quality Feedback/ Feedforward

Team Concept Period Fixed Ordering System/ Order Parts Quality System Management

Controlled External Transportation

Total Productive Maintenance

Scheduled Shipping / Receiving

Business Plan Deployment

Internal Pull / Delivery

Level Vehicle Order Schedules

Supply Continuous Chain Lean Design of Facilities, Equipment, Improvement Management Tooling and Layout Process

Problem Solving

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 142

GMS

Problem Solving

?

What Is a Problem? A Problem Is Defined As a Discrepancy Between an Existing Standard or Expectation and the Actual Situation

Standard Discrepancy

LEVEL

Actual

TIME

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 143

Create a Company Culture Where “Red” is not Always Bad!

?

? ?

GMS

Problems Are Seeds for Improvement – Don?t Hide them, Let them Rise Up!

Everyone has Problems – the Difference is in how they deal with them! If There Are No Problems, Then Something Is Wrong!

Growing

?No Problem? means Big Problem!

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 144

Problem Solving

Blame The Process – Not The People!!!

GMS

Problems Occur Because of Failures in the System

J Hamalian

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide

145

Guiding Principles

Everyone is responsible for Problem Solving!

Team Member Team Leader

GMS

Group Leader

Section Leader

Material

Engineer

Manager

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 146

GMS

Practical Problem Solving

Follow-Up & Check

Long-term Countermeasure 6

Problem Description

7

1

2

Problem Definition

5

Root Cause Investigation

4

3 Short-term

Containment

Locate Point of Cause

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 147

Practical Problem Solving Can Be Used For Anything!…

?When

GMS

is Problem Solving appropriate …

- Safety Incident - Significant Customer Dissatisfier - Lost Time Issues - Late Delivery of Good or Service

and any other abnormal situations at anywhere

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 148

Why is Problem Solving Part of Continuous Improvement?

Traditional Companies Stop at Temporary Fixes – They Just Contain the Problem and Put on a Band-Aid

GMS

?

That’s Not Real Improvement – It is Just Getting Back to Standard!

World-Class Companies Find The Root Cause and Put in Steps to Prevent It From Happening Again

GMS Executive Overview

?

Now, THAT is Continuous Improvement!!!

J Hamalian

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 149

Continuous Improvement

Continuous Improvement Process

GMS

Vision/ Mission

Shop Floor Management

People Involvement

Open Communication Process Team Concept

Small Lot Packaging

Values

Health and Safety Priority

Simple Process Flow Andon Concept

Manufacturing Process Validation Management by TAKT Time Workplace Organization

Product Quality Standards

Quality Feedback/ Feedforward

Fixed Period Ordering System/ Order Parts

Controlled External Transportation

Total Productive Maintenance

Internal Pull / Delivery Level Vehicle Order Schedules

Quality Scheduled System Shipping / Management Receiving

Business Plan Deployment

Supply Continuous Chain Lean Design of Facilities, Equipment, Improvement Tooling and Layout Management Process

Problem Solving

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 150

Continuous Improvement Culture

Create an Environment where People are driven to Continuously seek Improvement through the Elimination of Waste

GMS

Set challenging hurdles, conquer them, then raise the bar!!

J Hamalian

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 151

Continuous Improvement Culture

When You Climb to the Top . . .

GMS

. . .You Can See the Next Target!

GMS Executive Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 152

Continuous Improvement Culture

Improvement Is the Relentless Pursuit of the Elimination of the Enemy - WASTE!!

GMS

Safety

7 Types of

Quality

Waste

Improve

Cost Productivity

Never Be Satisfied With The Status Quo!

GMS Executi

ve Overview

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 153

What is the CIP Method?

1) Grasp the Current Situation 2) Imagine the Ideal Situation – Set Target Make Challenging Targets, Set Expectations – Use BPD

GMS

3) Compare Current Situation to Ideal - See the Gap

4) Define Strategy to Achieve the Ideal 5) Implement CIPs 6) Follow-Up Kaizen/CIP Small Ideas Value Stream Mapping

Ideal

Gap

Suggestion Program

Kaizen/CIP Teams & Workshops

GMS Executive Overview

Go Fast!

Now

GM Confidential Version Date 2004.8.12

John S. Hamalian

Slide 154

What is the Difference Between Problem Solving and Continuous Improvement Process (CIP)?

Standard

GMS

Problem Solving

Actual

Problem Solving is Getting Back to Standard and Staying There

New Standard