一 : NeotecWELLFLOV8.1.6

下图为Neotec WELLFLO V8.1.6版

联系邮箱:zhongtiany01@163.com

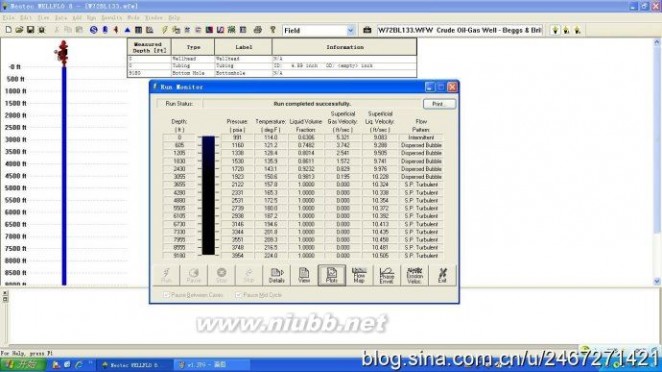

油气井生产、欠平衡钻井/控压钻井水力学模拟软件WELLFLO软件是SPTGroup—Neotec公司经过36年研发和实践编制出的油气井生产、欠平衡钻井/控压钻井水力学模拟软件。用来模拟生产井或注入井的水力学和传热过程,WELLFLO提供三个用户界面包括WELLFLOExpert、WELLFLO Rigsite、WELLFLO Production.

WELLFLO可用于模拟人工举升,多层开采、欠平衡钻井、油套管合采以及井筒加热注蒸汽等工艺过程;能准确计算井筒多相流压力温度变化,尤其对凝析气/高酸性气体更准确,能够预测和预防井筒积液,优化井的生产制度;WELLFLO能够对稠油井采油工艺进行评估,模拟复杂流体流动,优化环空设计,预测水合物生成。动态和静态两种模式的结合满足了快速设计和详细分析两方面的需要,这样使用户可以获得最优方案。

| WELLFLO软件功能 · 人工举升(气举,ESP) · 多层合采 · 油套管合采 · 隔热油管 · 环空电加热 · 井筒加热 · 注蒸汽 · 井稳定性分析 | 欠平衡钻井/压力控制钻井中的应用 · 优化注入压力和注入量 · 评估UBD需要的钻井液 · 监控钻井过程 |

二 : 欢度6.1

六一儿童节是儿童的盛宴。在儿童节里,我们欢庆着属于自己的时光。今天是一年一度的六一儿童节,每一位同学的脸上都挂着欣喜、快乐的笑容。我们来到学校的大礼堂,准备参加六一儿童节歌咏大赛,和其他班的同学来个PK比赛!都说儿童的歌声是天籁之音。果不其然,每个班都唱得那么好。我最喜欢的就数六(1)班的《虫儿飞》了。同学们站在舞台上,缓缓的抒情音乐响起,大家轻轻唱了起来:“黑黑的天空低垂,亮亮的繁星相随……”我们好像真的到了一个仙境般的地方,到处都是闪着微弱的光芒的萤火虫,萦绕在我们的身边。夜空上的繁星一闪一闪,微风吹拂着我们,好似在诉说一个美丽的故事。萤火虫飞啊飞啊,跳着美丽的舞蹈,在我们身边旋转、舞蹈……一曲终了,我们才清醒过来,意犹未尽,还想再听一遍。终于轮到我们上场了!我们走上台,微笑着面对观众。音乐响起,清脆的歌声也随之响起,流淌在同学们之间。第一首是《让我们荡起双桨》。唱着,唱着,大家好像真的坐在小船里,一边划船一边唱歌。小船儿漂啊漂,伴着同学们一起歌唱,直到音乐结束。大家还没缓过神来呢,轻快、活泼的乐曲就又响了起来。哦!《蜗牛与黄鹂鸟》已经开始了。我们立刻换上了一副高兴的笑容,倾情演唱这首歌。大家好像也被我们感染了一样,俏皮的笑容展开在脸上。活动在同学们的歌声、笑声中结束了。虽然比赛我们只得了第三名,但是名次不是重要的,只要开心就好了,不是吗?

树人六年级:王鑫

三 : Eurocode3-1-6

CEN/TC250/SC3/

EUROPEAN STANDARD prEN 1993-1-6 : 2004 NORME EUROPéENNE

EUROP?ISCHE NORM Oct 2004

___________________________________

UDC

Descriptors:

English version

Eurocode 3: Design of steel structures

Part 1-6 : Strength and Stability of Shell Structures

Calcul des structures en acier

Partie 1.6 :

Resistance et Stabilité des Coques

Bemessung und Konstruktion von Stahlbauten Teil 1.6 : Aus Schalen

Stage 49 ? draft

5 October 2004

CEN

European Committee for Standardisation Comité Européen de Normalisation Europ?isches Komitee für Normung

Central Secretariat: rue de Stassart 36, B-1050 Brussels

_______________________________

Ref. No. EN 1993-1.6 : 20xx. E

? CEN Copyright reserved to all CEN members

tiffen Eurocode3-1-6

Page 2

EN 1993-1-6: 20xx Contents Page

1. Introduction

1.1 Scope 1.2 Normative references 1.3 Definitions 1.4 Symbols 1.5 Sign conventions 2

Basis of design and modelling 2.1 General 2.2 Types of analysis

2.3 Shell boundary conditions 3 Materials and geometry

3.1 Material properties

3.2 Design values of geometrical data

3.3 Geometrical tolerances and geometrical imperfections 4

Ultimate limit states in steel shells 4.1 Ultimate limit states to be considered

4.2 Design concepts for the limit states design of shells

5

Stress resultants and stresses in shells 5.1 Stress resultants in the shell

5.2 Modelling of the shell for analysis 5.3 Types of analysis

6 Plastic limit state (LS1)

6.1 Design values of actions 6.2 Stress design

6.3 Design by global numerical MNA or GMNA analysis 6.4 Direct design

7 Cyclic plasticity limit state (LS2)

7.1 Design values of actions 7.2 Stress design

7.3 Design by global numerical MNA or GMNA analysis 7.4 Direct design

8 Buckling limit state (LS3)

8.1 Design values of actions

8.2 Special definitions and symbols

8.3 Buckling-relevant boundary conditions 8.4 Buckling-relevant geometrical tolerances 8.5 Stress design

8.6 Design by global numerical analysis using MNA and LBA analyses 8.7 Design by global numerical GMNIA analysis

9 Fatigue limit state (LS4)

9.1 Design values of actions 9.2 Stress design

9.3 Design by global numerical LA or GNA analysis

5 5 6 6 10 13 14 14 14 16 17 17 17 17 18 18 19 22 22 22 24 25 25 25 26 26 28 28 28 28 29 30 30 30 30 30 36 38 40 45 45 45 46

tiffen Eurocode3-1-6

ANNEX A (normative)

Membrane theory stresses in shells

A.1 General

A.2 Unstiffened Cylindrical Shells A.3 Unstiffened Conical Shells A.4 Unstiffened Spherical Shells ANNEX B (normative)

Additional expressions for plastic collapse resistances

B.1 General B.2 Unstiffened cylindrical shells B.3 Ring stiffened cylindrical shells B.4 Junctions between shells

B.5 Circular plates with axisymmetric boundary conditions ANNEX C (normative)

Expressions for linear elastic membrane and bending stresses

C.1 General

C.2 Clamped base unstiffened cylindrical shells C.3 Pinned base unstiffened cylindrical shells

C.4 Internal conditions in unstiffened cylindrical shells C.5 Ring stiffener on cylindrical shell

C.6 Circular plates with axisymmetric boundary conditions ANNEX D [normative]

Expressions for buckling stress design

D.1 Unstiffened cylindrical shells of constant wall thickness

D.2 Unstiffened cylindrical shells of stepwise variable wall thickness D.3 Unstiffened lap jointed cylindrical shells

D.4 Unstiffened complete and truncated conical shells

Page 3

EN 1993-1-6: 20xx

47 47 47 48 49 50 51 51 51 52 54 56 58 59 59 59 60 62 64 66 67 69 69 69 78 82 84

tiffen Eurocode3-1-6

Page 4

EN 1993-1-6: 20xx

National annex for EN 1993-1-6

This standard gives alternative procedures, values and recommendations with notes indicating where national choices may have to be made. Therefore the National Standard implementing EN 1993-1-6 should have a National Annex containing all Nationally Determined Parameters to be used for the design of steel structures to be constructed in the relevant country.

National choice is allowed in EN 1993-1-6 through:

?

?

? 4.1.4 (3) 5.2.4 (1) 6.3 (5)

? 7.3.1 (5)

? 7.3.2 (1)

?

?

? 8.4.2 Table 8.1 8.4.3 Tables 8.2 and 8.3 8.4.4 Table 8.4

? 8.4.5 (1)

? 8.5.2 (2)

?

?

8.7.2 Table 8.5 8.7.2 (7), (16) and (18) ? 9.2.1 (2)

tiffen Eurocode3-1-6

Page 5

EN 1993-1-6: 20xx

1. Introduction

1.1 Scope

(1) EN 1993-1-6 gives design requirements for plated steel structures that have the form of a shell of revolution.

(2) This Standard is intended for use in conjunction with EN 1993-1-1, EN 1993-1-3, EN 1993-1-4, EN 1993-1-9 and the relevant application parts of EN 1993, which include:

扩展:eurocode3 中文版 / eurocode 3 / eurocode3 中文

? Part 3.1 for towers and masts;

? Part 3.2 for chimneys;

? Part 4.1 for silos;

? Part 4.2 for tanks;

? Part 4.3 for pipelines.

(3) This Standard defines the characteristic and design values of the resistance of the structure.

(4) This Standard is concerned with the requirements for design against the ultimate limit states of: ? plastic limit;

? cyclic plasticity;

? buckling;

? fatigue.

(5) Overall equilibrium of the structure (sliding, uplifting, overturning) is not included in this Standard, but is treated in EN 1993-1-1. Special considerations for specific applications are included in the relevant applications parts of EN 1993.

(6) The provisions in this Standard apply to axisymmetric shells and associated circular or annular plates and to beam section rings and stringer stiffeners where they form part of the complete structure. The following shell forms are covered: cylinders, cones and spherical caps.

(7) Cylindrical, conical and spherical panels are not explicitly covered by this Standard. However, the provisions can be applicable if the appropriate boundary conditions are duly taken into account.

(8) This Standard is intended for application to structural engineering steel shell structures. However, its provisions can be applied to other metallic shells provided that the appropriate material properties are duly taken into account.

(9) The provisions of this Standard are intended to be applied within the temperature range defined in the relevant EN 1993 application parts. The maximum temperature is restricted so that the influence of creep can be neglected if high temperature creep effects are not covered by the relevant application part.

(10) The provisions in this Standard apply to structures that satisfy the brittle fracture provisions given in EN 1993-1-10.

(11) The provisions of this Standard apply to structural design under actions that can be treated as quasi-static in nature.

(12) In this Standard, it is assumed that both wind loading and bulk solids flow can, in general, be treated as quasi-static actions.

(13) Dynamic effects should be taken into account according to the relevant application part of EN 1993, including the consequences for fatigue. However, the stress resultants arising from dynamic behaviour are treated in this part as quasi-static.

(14) The provisions in this Standard apply to structures that are constructed in accordance with EN 1090.

(15) This Standard does not cover the aspects of leakage of contents.

tiffen Eurocode3-1-6

Page 6

EN 1993-1-6: 20xx

(16) This Standard is not intended for application to structures outside the following limits:

? design metal temperatures outside the range ?50°C to +300°C;

? radius to thickness ratios outside the range 20 to 5000.

NOTE: It should be noted that the hand calculation rules of this standard may be rather conservative when applied to some geometries and loading conditions for relatively thick-walled shells.

1.2 Normative references

(1) This European Standard incorporates, by dated or undated reference, provisions from other publications. These normative references are cited at the appropriate places in the text and the publications are listed hereafter. For dated references, subsequent amendments to or revisions of any of these publications apply to this European Standard only when incorporated in it by amendment or revision. For undated references the latest edition of the publication referred to applies.

EN 1090

EN 1990

EN 1991 EN 1993

Part 1.1:

Part 1.3:

Part 1.4:

Part 1.5:

Part 1.9:

Part 1.10:

Part 2:

Part 3.1:

Part 3.2:

Part 4.1:

Part 4.2:

Part 4.3:

EN 13084

Part 7:

Execution of steel structures: Basis of design; Eurocode 3: Design of steel structures: General rules and rules for buildings; Cold formed members and sheeting; Stainless steels; Plated structural elements; Fatigue; Material toughness and through-thickness properties; Steel bridges; Towers and masts; Chimneys; Silos; Tanks; Pipelines. Free standing chimneys: Product specification of cylindrical steel fabrications for use in single wall steel chimneys and steel liners.

1.3 Definitions

The terms that are defined in EN 1990 for common use in the Structural Eurocodes apply to this Standard. Unless otherwise stated, the definitions given in ISO 8930 also apply in this Standard. Supplementary to EN 1993-1-1, for the purposes of this Standard, the following definitions apply:

1.3.1 Structural forms and geometry

1.3.1.1

shell

A structure or a structural component formed from a curved thin plate.

tiffen Eurocode3-1-6

Page 7

EN 1993-1-6: 20xx

1.3.1.2

shell of revolution

扩展:eurocode3 中文版 / eurocode 3 / eurocode3 中文

A shell whose form is defined by a meridional generator line rotated around a single axis through 2π radians. The shell can be of any length.

1.3.1.3

complete axisymmetric shell

A shell composed of a number of parts, each of which is a shell of revolution.

1.3.1.4

shell segment

A shell of revolution in the form of a defined shell geometry with a constant wall thickness: a cylinder, conical frustum, spherical frustum, annular plate, toroidal knuckle or other form.

1.3.1.5

shell panel

An incomplete shell of revolution: the shell form is defined by a rotation of the generator about the axis through less than 2π radians.

1.3.1.6

middle surface

The surface that lies midway between the inside and outside surfaces of the shell at every point. Where the shell is stiffened on only one surface, the reference middle surface is still taken as the middle surface of the curved shell plate. The middle surface is the reference surface for analysis, and can be discontinuous at changes of thickness or shell junctions, leading to eccentricities that may be important to the shell structural behaviour.

1.3.1.7

junction

The point at which two or more shell segments meet: it can include a stiffener or not: the point of attachment of a ring stiffener to the shell may be treated as a junction.

1.3.1.8

stringer stiffener

A local stiffening member that follows the meridian of the shell, representing a generator of the shell of revolution. It is provided to increase the stability, or to assist with the introduction of local loads. It is not intended to provide a primary resistance to bending effects caused by transverse loads.

1.3.1.9

rib

A local member that provides a primary load carrying path for bending down the meridian of the shell, representing a generator of the shell of revolution. It is used to transfer or distribute transverse loads by bending.

1.3.1.10

ring stiffener

A local stiffening member that passes around the circumference of the shell of revolution at a given point on the meridian. It is assumed to have no stiffness in the meridional plane of the shell. It is provided to increase the stability or to introduce axisymmetric local loads acting in the plane of the ring by a state of axisymmetric normal forces. It is not intended to provide primary resistance for bending.

1.3.1.11

base ring

A structural member that passes around the circumference of the shell of revolution at the base and provides means of attachment of the shell to a foundation or other structural member. It is needed to ensure that the assumed boundary conditions are achieved in practice.

1.3.1.12

ring beam or ring girder

A circumferential stiffener that has bending stiffness and strength both in the plane of the shell circular section and normal to that plane. It is a primary load carrying structural member, provided for the distribution of local loads into the shell.

tiffen Eurocode3-1-6

Page 8

EN 1993-1-6: 20xx

1.3.2 Limit states

1.3.2.1

plastic limit

The ultimate limit state where the structure develops zones of yielding in a pattern such that its ability to resist increased loading is deemed to be exhausted. It can be related to a small deflection theory limit load or plastic collapse mechanism.

1.3.2.2

tensile rupture

The ultimate limit state where the shell plate experiences gross section failure due to tension.

1.3.2.3

cyclic plasticity

The ultimate limit state where repeated yielding is caused by cycles of loading and unloading, leading to a low cycle fatigue failure where the energy absorption capacity of the material is exhausted.

1.3.2.4

buckling

The ultimate limit state where the structure suddenly loses its stability under membrane compression and/or shear. It leads either to large displacements or to the structure being unable to support the applied loads.

1.3.2.5

fatigue

The ultimate limit state where many cycles of loading cause cracks to develop of the shell plate.

1.3.3 Actions

1.3.3.1

axial load

Externally applied loading acting in the axial direction.

1.3.3.2

radial load

Externally applied loading acting normal to the surface of a cylindrical shell.

1.3.3.3

internal pressure

Component of the surface loading acting axisymmetrically, normal to the shell in the outward direction. Its magnitude can vary in both the meridional and circumferential directions (e.g. under solids loading in a silo).

1.3.3.4

external pressure

Component of the surface loading acting axisymmetrically, normal to the shell in the inward direction. It magnitude can vary in both the meridional and circumferential directions (e.g. under wind).

1.3.3.5

hydrostatic pressure

扩展:eurocode3 中文版 / eurocode 3 / eurocode3 中文

Pressure varying linearly with the axial coordinate of the shell of revolution.

1.3.3.6

wall friction load

Meridional component of the surface loading acting along the wall due to friction connected with internal pressure (when solids are contained within the shell).

1.3.3.7

local load

Point applied force or distributed load acting on a limited part of the circumference of the shell and over a limited height.

1.3.3.8

patch load

Local distributed load acting normal to the shell.

tiffen Eurocode3-1-6

Page 9

EN 1993-1-6: 20xx

1.3.3.9

suction

Constant external pressure due to the sucking effect of the wind action on a shell with openings or vents.

1.3.3.10

partial vacuum

Constant external pressure due to the removal of stored liquids or solids from within a container with inadequate venting.

1.3.3.11

thermal action

Temperature variation either along or around the shell or through the shell thickness.

1.3.4 Types of analysis

1.3.4.1

global analysis

An analysis that includes the complete structure, rather than individual structural parts treated separately.

1.3.4.2

membrane theory analysis

An analysis that predicts the behaviour of a thin-walled shell structure under distributed loads by adopting a set of membrane forces that satisfy equilibrium with the external loads.

1.3.4.3

linear elastic shell analysis (LA)

An analysis that predicts the behaviour of a thin-walled shell structure on the basis of the small deflection linear elastic shell bending theory, related to the perfect geometry of the middle surface of the shell.

1.3.4.4

linear elastic bifurcation (eigenvalue) analysis (LBA)

An analysis that evaluates the linear bifurcation eigenvalue for a thin-walled shell structure on the basis of the small deflection linear elastic shell bending theory, related to the perfect geometry of the middle surface of the shell. It should be noted that, where an eigenvalue is mentioned, this does not relate to vibration modes.

1.3.4.5

geometrically nonlinear elastic analysis (GNA)

An analysis based on the principles of shell bending theory applied to the perfect structure, using a linear elastic material law but including nonlinear, large deflection theory for the displacements. A bifurcation eigenvalue check is included at each load level.

1.3.4.6

materially nonlinear analysis (MNA)

An analysis based on shell bending theory applied to the perfect structure, using the assumption of small deflections, as in 1.3.4.3, but adopting a nonlinear elasto-plastic material law.

1.3.4.7

geometrically and materially nonlinear analysis (GMNA)

An analysis based on shell bending theory applied to the perfect structure, using the assumptions of nonlinear, large deflection theory for the displacements and a nonlinear, elasto-plastic material law. A bifurcation eigenvalue check is included at each load level.

1.3.4.8

geometrically nonlinear elastic analysis with imperfections included (GNIA)

An analysis with imperfections included, similar to a GNA analysis as defined in 1.3.4.5, but adopting a model for the geometry of the structure that includes the imperfect shape (i.e. the geometry of the middle surface includes unintended deviations from the ideal shape). A bifurcation eigenvalue check is included at each load level.

tiffen Eurocode3-1-6

Page 10

EN 1993-1-6: 20xx

1.3.4.9

geometrically and materially nonlinear analysis with imperfections included (GMNIA)

An analysis with imperfections included, similar to the GMNA analysis as defined in 1.3.4.7, but adopting a model for the geometry of the structure that includes the imperfect shape (i.e. the geometry of the middle surface includes unintended deviations from the ideal shape). A bifurcation eigenvalue check is included at each load level.

1.3.5 Special definitions for buckling calculations

1.3.5.1

critical buckling resistance

The smallest bifurcation or limit load determined assuming the idealised conditions of elastic material behaviour, perfect geometry, perfect load application, perfect support, material isotropy and absence of residual stresses (LBA analysis).

1.3.5.2

critical buckling stress

The nominal membrane stress (based on membrane theory) associated with the elastic critical buckling resistance.

1.3.5.3

characteristic buckling stress

The nominal membrane stress associated with buckling in the presence of inelastic material behaviour, the geometrical and structural imperfections that are inevitable in practical construction, and follower load effects.

1.3.5.4

design buckling stress

The design value of the buckling stress, obtained by dividing the characteristic buckling stress by the partial factor for resistance.

扩展:eurocode3 中文版 / eurocode 3 / eurocode3 中文

1.3.5.5

key value of the stress

The value of stress in a non-uniform stress field that is used to characterise the stress magnitudes in an LS3 assessment.

1.3.5.6

fabrication tolerance quality class

The category of fabrication tolerance requirements that is assumed in design.

1.4 Symbols

(1)

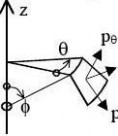

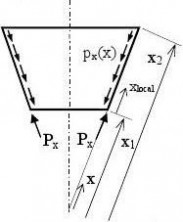

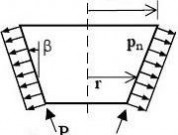

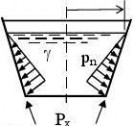

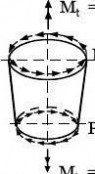

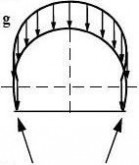

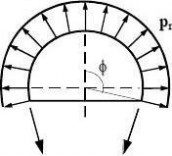

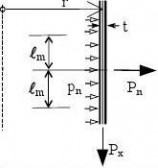

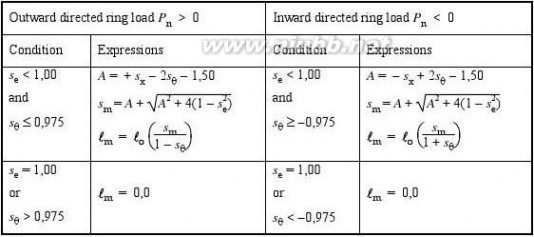

(2) In addition to those given in EN 1990 and EN 1993-1-1, the following symbols are used: Coordinate system (see figure 1.1):

r radial coordinate, normal to the axis of revolution;

x meridional coordinate;

z axial coordinate;

θ circumferential coordinate;

φ meridional slope: angle between axis of revolution and normal to the meridian of the shell;

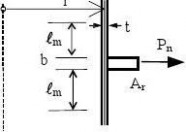

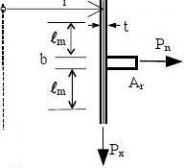

(3) Pressures:

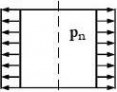

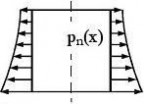

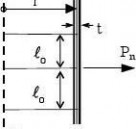

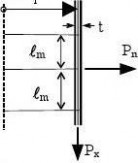

pn normal to the shell;

meridional surface loading parallel to the shell; px

circumferential surface loading parallel to the shell; pθ

(4) Line forces:

Pn load per unit circumference normal to the shell;

load per unit circumference acting in the meridional direction; Px

Pθ load per unit circumference acting circumferentially on the shell;

tiffen Eurocode3-1-6

Page 11

EN 1993-1-6: 20xx

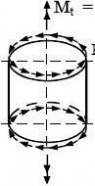

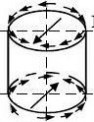

(5) Membrane stress resultants:

nx meridional membrane stress resultant;

circumferential membrane stress resultant; nθ

membrane shear stress resultant; nxθ

Bending stress resultants:

mx meridional bending moment per unit width;

circumferential bending moment per unit width; mθ

twisting shear moment per unit width; mxθ

transverse shear force associated with meridional bending; qxn

transverse shear force associated with circumferential bending; qθn (6)

(7) Stresses:

σx meridional stress;

stress; σθ circumferential

von Mises equivalent stress (can be negative in cyclic loading conditions); σeq

τ, τxθ in-plane shear stress;

τxn, τθn meridional, circumferential transverse shear stresses associated with bending;

(8) Displacements:

u meridional displacement;

v circumferential displacement;

w displacement normal to the shell surface;

βφ meridional rotation (see 5.2.2);

(9) Shell dimensions:

d internal diameter of shell;

L total length of the shell;

? length of shell segment;

?g gauge length for measurement of imperfections;

gauge length for measurement of imperfections in circumferential direction; ?gθ

gauge length for measurement of imperfections across welds; ?gw

limited length of shell for buckling strength assessment; ?R

r radius of the middle surface, normal to the axis of revolution; t thickness of shell wall;

maximum thickness of shell wall at a joint; tmax

minimum thickness of shell wall at a joint; tmin

tave average thickness of shell wall at a joint;

β apex half angle of cone;

tiffen Eurocode3-1-6

Page 12

EN 1993-1-6: 20xx

n

x

θ

vDisplacements

σx

x

Directions

Membrane stresses

ττθTransverse shear

stresses

Figure 1.1: Symbols in shells of revolution

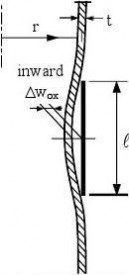

(10) Tolerances (see 8.4):

e eccentricity between the middle surfaces of joined plates; Ue accidental eccentricity tolerance parameter;

out-of-roundness tolerance parameter; Ur

initial dimple imperfection amplitude parameter for numerical calculations; Un

initial dimple tolerance parameter; U0

tolerance normal to the shell surface; ?w0

(11) Properties of materials:

E Young’s modulus of elasticity; feq von Mises equivalent strength;

yield strength; fy

ultimate strength; fu

ν Poisson’s ratio;

(12) Parameters in strength assessment:

C coefficient in buckling strength assessment; D cumulative damage in fatigue assessment; F generalised action; R calculated resistance (used with subscripts to identify the basis);

plastic reference resistance (defined as a load factor on design loads); Rpl

elastic critical buckling resistance (defined as a load factor on design loads); Rcr

k calibration factor for nonlinear analyses; k power of interaction expressions in buckling strength interaction expressions; n number of cycles of loading; α elastic imperfection reduction factor in buckling strength assessment; β plastic range factor in buckling interaction; γ partial factor; ? range of parameter when alternating or cyclic actions are involved;

扩展:eurocode3 中文版 / eurocode 3 / eurocode3 中文

strain; εp plastic

η interaction exponent for buckling; ?λ relative slenderness of shell; ?overall relative slenderness for the complete shell (multiple segments); λov

tiffen Eurocode3-1-6

Page 13

EN 1993-1-6: 20xx

?λ0 ?λ

ω

χ

χov psquash limit relative slenderness (value of ?λ at which stability reductions commence); ?plastic limit relative slenderness (value of λ below which plasticity affects the stability); relative length parameter for shell; buckling reduction factor for elastic-plastic effects in buckling strength assessment; overall buckling resistance reduction factor for complete shell;

(13) Subscripts:

E value of stress or displacement (arising from design actions);

F actions;

M material;

R resistance;

S value of stress resultant (arising from design actions);

cr critical buckling value;

d design value;

int internal;

k characteristic value;

max maximum value;

min minimum value;

nom nominal value;

pl plastic value;

u ultimate;

y yield.

(14) Further symbols are defined where they first occur.

1.5 Sign conventions

(1) Outward direction positive: internal pressure positive, outward displacement positive, except as noted in (4).

(2) Tensile stresses positive, except as noted in (4).

NOTE: Compression is treated as positive in EN 1993-1-1.

(3) Shear stresses positive as shown in figures 1.1 and D.1.

(4) For simplicity, in section 8 and Annex D, compressive stresses are treated as positive. For these cases, both external pressures and internal pressures are treated as positive where they occur.

tiffen Eurocode3-1-6

Page 14

EN 1993-1-6: 20xx

2 Basis of design and modelling

2.1 General

(1) The basis of design shall be in accordance with EN 1990, as supplemented by the following.

(2) In particular, the shell shall be designed in such a way that it will sustain all actions and satisfy the following requirements:

? overall equilibrium;

? equilibrium between actions and internal forces and moments (see sections 6 and 8);

? limitation of cracks due to cyclic plastification (see section 7);

? limitation of cracks due to fatigue (see section 9).

(3) The design of the shell shall satisfy the serviceability requirements set out in the appropriate application standard (EN 1993 Parts 3.1, 3.2, 4.1, 4.2, 4.3).

(4) The shell may be proportioned using design assisted by testing. Where appropriate, the requirements are set out in the appropriate application standard (EN 1993 Parts 3.1, 3.2, 4.1, 4.2, 4.3).

(5) All actions should be introduced using their design values according to EN 1991 and EN 1993 Parts 3.1,

3.2, 4.1, 4.2, 4.3 as appropriate.

2.2 Types of analysis

2.2.1 General

(1) One or more of the following types of analysis should be used as detailed in section 4, depending on the limit state and other considerations:

? Global analysis (see 2.2.2);

? Membrane theory analysis (see 2.2.3);

? Linear elastic shell analysis (see 2.2.4);

? Linear elastic bifurcation analysis (see 2.2.5);

? Geometrically nonlinear elastic analysis (see 2.2.6);

? Materially nonlinear analysis (see 2.2.7);

? Geometrically and materially nonlinear analysis (see 2.2.8);

? Geometrically nonlinear elastic analysis with imperfections included (see 2.2.9);

? Geometrically and materially nonlinear analysis with imperfections included (see 2.2.10).

2.2.2 Global analysis

(1) A global analysis may involve approximate treatments of certain parts of the structure.

2.2.3 Membrane theory analysis

(1) A membrane theory analysis should not be used unless the following conditions are met:

? the boundary conditions are appropriate for transfer of the stresses in the shell into support reactions without causing bending effects;

? the shell geometry varies smoothly in shape (without discontinuities);

? the loads have a smooth distribution (without locally concentrated or point loads).

(2) A membrane theory analysis does not necessarily fulfil the compatibility of deformations at boundaries or between shell segments of different shape or between shell segments subjected to different loading. However, the resulting field of membrane forces satisfies the requirements of primary stresses (LS1).

2.2.4 Linear elastic shell analysis (LA)

(1) The linearity of the theory results from the assumptions of a linear elastic material law and the linear small deflection theory. Small deflection theory implies that the assumed geometry remains that of the undeformed structure.

(2) An LA analysis satisfies compatibility in the deformations as well as equilibrium. The resulting field of membrane and bending stress matches the requirements of primary plus secondary stresses (LS2).

扩展:eurocode3 中文版 / eurocode 3 / eurocode3 中文

tiffen Eurocode3-1-6

Page 15

EN 1993-1-6: 20xx

2.2.5 Linear elastic bifurcation analysis (LBA)

(1) The conditions of 2.2.4 concerning the material and geometric assumptions are met. However, this linear bifurcation analysis obtains the lowest eigenvalue at which the shell may buckle into a different deformation mode, assuming no change of geometry, no change in the direction of action of the loads, and no material degradation. Imperfections of all kinds are ignored. This analysis provides the basis of the critical buckling resistance evaluation (LS3).

2.2.6 Geometrically nonlinear elastic analysis (GNA)

(1) A GNA analysis satisfies both equilibrium and compatibility of the deflections under conditions in which the change in the geometry of the structure caused by loading is included. The resulting field of stresses matches the definition of primary plus secondary stresses (LS2).

(2) Where compression or shear stresses are predominant in some part of the shell, a GNA analysis delivers the elastic buckling load of the perfect structure, including changes in geometry, that may be of assistance in checking the limit state LS3 (see 8.7).

(3) Where this analysis is used for a buckling load evaluation, the eigenvalues of the system must be checked to ensure that the numerical process does not fail to detect a bifurcation in the load path.

2.2.7 Materially nonlinear analysis (MNA)

(1) The result of an MNA analysis gives the plastic limit load, which can be interpreted as a load amplification factor R on the design value of the loads FEd. This may be used to verify limit state LS1. An MNA analysis can also be used to give the plastic strain increment ?ε during one cycle of cyclic loading. This may be used to verify limit state LS2.

2.2.8 Geometrically and materially nonlinear analysis (GMNA)

(1) The result of a GMNA analysis, analogously to 2.2.5, gives the geometrically nonlinear plastic limit load of the perfect structure and the plastic strain increment, that may be used for checking the limit states LS1 and LS2.

(2) Where compression or shear stresses are predominant in some part of the shell, a GMNA analysis gives the elasto-plastic buckling load of the perfect structure, that may be of assistance in checking the limit state LS3 (see 8.7).

(3) Where this analysis is used for a buckling load evaluation, the eigenvalues of the system must be checked to ensure that the numerical process does not fail to detect a bifurcation in the load path.

2.2.9 Geometrically nonlinear elastic analysis with imperfections included (GNIA)

(1) A GNIA analysis is used in cases where compression or shear stresses dominate in the shell. It delivers elastic buckling loads of the "real" imperfect structure, that may be of assistance in checking the limit state LS3 (see 8.7).

(2) Where this analysis is used for a buckling load evaluation, the eigenvalues of the system must be checked to ensure that the numerical process does not fail to detect a bifurcation in the load path.

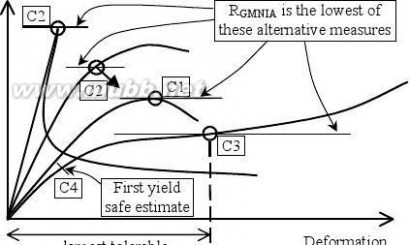

2.2.10 Geometrically and materially nonlinear analysis with imperfections included (GMNIA)

(1) A GMNIA analysis is used in cases where compression or shear stresses are dominant in the shell. It delivers elasto-plastic buckling loads for the "real" imperfect structure, that may be used for checking the limit state LS3.

(2) Where this analysis is used for a buckling load evaluation, the eigenvalues of the system must be checked to ensure that the numerical process does not fail to detect a bifurcation in the load path.

(3) Where this analysis is used for a buckling load evaluation, an additional GMNA analysis of the perfect shell should always be conducted to ensure that the degree of imperfection sensitivity of the structural system is identified.

tiffen Eurocode3-1-6

Page 16

EN 1993-1-6: 20xx

2.3 Shell boundary conditions

(1) The boundary conditions assumed in the design calculation shall be chosen in such a way as to ensure that they achieve a realistic or conservative model of the real construction. Special attention shall be given not only to the constraint of displacements normal to the shell wall (deflections), but also to the constraint of the displacements in the plane of the shell wall (meridional and circumferential) because of the significant effect these have on shell strength and buckling resistance.

(2) In shell buckling (eigenvalue) calculations (limit state LS3), the definition of the boundary conditions shall refer to the incremental displacements during the buckling process, and not to total displacements induced by the applied actions before buckling.

(3) The boundary conditions at a continuously supported lower edge of a shell shall take into account whether local uplifting of the shell is prevented or not.

(4) The shell edge rotation βφ should be particularly considered in short shells and in the calculation of secondary stresses in longer shells (according to the limit states LS2 and LS4).

扩展:eurocode3 中文版 / eurocode 3 / eurocode3 中文

(5) The boundary conditions set out in 5.2.2 should be used in computer analyses and in selecting expressions from Annexes A to D.

(6) The structural connections between shell segments at a junction should be such as to ensure that the boundary condition assumptions used in the design of the individual shell segments are satisfied.

tiffen Eurocode3-1-6

Page 17

EN 1993-1-6: 20xx

3 Materials and geometry

3.1 Material properties

(1) The material properties of steels should be obtained from the relevant applications standards.

(2) Where materials with nonlinear stress-strain curves are involved and a buckling analysis is carried out under stress design (see 8.5), the initial tangent value of Young′s modulus E should be replaced by a reduced value. If no better method is available, the secant modulus at the 0,2% proof stress should be used when assessing the critical load or critical stress.

(3) Where the temperature exceeds 100°C, the material properties should be obtained from EN 13084-7.

(4) In a global numerical analysis using material nonlinearity, the stress-strain curve should be obtained from EN 1993-1-5 Annex C for carbon steels and EN 1993-1-4 Annex C for stainless steels.

3.2 Design values of geometrical data

(1) The thickness t of the shell shall be taken as defined in the relevant application standard. If no application standard is relevant, the nominal thickness of the wall, reduced by the prescribed value of the corrosion loss, shall be used.

(2) The thickness ranges within which the rules of this Standard may be applied are defined in the relevant EN 1993 application parts.

(3) The middle surface of the shell shall be taken as the reference surface for loads.

(4) The radius r of the shell shall be taken as the nominal radius of the middle surface of the shell, measured normal to the axis of revolution.

(5) The buckling design rules of this Standard should not be applied outside the ranges of the r/t ratio set out in section 8 or Annex D or in the relevant EN 1993 application parts.

3.3 Geometrical tolerances and geometrical imperfections

(1) Tolerance values for the deviations of the geometry of the shell surface from the nominal values are defined in the execution standards due to the requirements of serviceability. Relevant items are:

? out-of-roundness (deviation from circularity),

? eccentricities (deviations from a continuous middle surface in the direction normal to the shell along junctions of plates),

? local dimples (local normal deviations from the nominal middle surface).

NOTE: Until there is a European standard for execution, the tolerances can be obtained from this standard or the relevant application standards.

(2) If the limit state of buckling (LS3, as described in 4.1.3) is one of the ultimate limit states to be considered, additional buckling-relevant geometrical tolerances have to be observed in order to keep the geometrical imperfections within specified limits. These buckling-relevant geometrical tolerances are quantified in section 8 or in the relevant EN 1993 application parts.

(3) Calculation values for the deviations of the shell surface geometry from the nominal geometry, as required for geometrical imperfection assumptions (overall imperfections or local imperfections) for the buckling design by global GMNIA analysis (see 8.7), shall be derived from the specified geometrical tolerances. Relevant rules are given in 8.7 or in relevant EN 1993 application parts.

tiffen Eurocode3-1-6

Page 18

EN 1993-1-6: 20xx

4 Ultimate limit states in steel shells

4.1 Ultimate limit states to be considered

4.1.1 LS1: Plastic limit

(1) The limit state of the plastic limit shall be taken as the condition in which the capacity of the structure to resist the actions on it is exhausted by yielding of the material. The resistance offered by the structure at the plastic limit state may be derived as the plastic collapse load obtained from a mechanism based on small displacement theory.

(2) The limit state of tensile rupture shall be taken as the condition in which the shell wall experiences gross section tensile failure, leading to separation of the two parts of the shell.

(3) In the absence of fastener holes, verification at the limit state of tensile rupture may be assumed to be covered by the check for the plastic limit state. However, where holes for fasteners occur, a supplementary check in accordance with 6.2 of EN 1993-1-1 should be carried out.

(4) In verifying the plastic limit state, plastic or partially plastic behaviour of the structure may be assumed (i.e. elastic compatibility considerations may be neglected).

NOTE: The basic characteristic of this limit state is that the load or actions sustained (resistance) cannot be increased without exploiting a significant change in the geometry of the structure or strain-hardening of the material.

扩展:eurocode3 中文版 / eurocode 3 / eurocode3 中文

(5) All relevant combinations of extreme loads shall be accounted for when checking LS1.

(6) The following methods of analysis (see 2.2) should be used for the calculation of the design stresses and stress resultants when checking LS1:

? membrane theory;

? expressions in Annexes A and B;

? linear elastic analysis (LA);

? materially nonlinear analysis (MNA);

? geometrically and materially nonlinear analysis (GMNA).

4.1.2 LS2: Cyclic plasticity

(1) The limit state of cyclic plasticity shall be taken as the condition in which repeated cycles of loading and unloading produce yielding in tension and in compression at the same point, thus causing plastic work to be repeatedly done on the structure, eventually leading to local cracking by exhaustion of the energy absorption capacity of the material.

NOTE: The stresses that are associated with this limit state develop under a combination of all actions and the compatibility conditions for the structure.

(2) All variable actions (such as imposed loads and temperature variations) that can lead to yielding, and which might be applied with more than three cycles in the life of the structure, shall be accounted for when checking LS2.

(3) In the verification of this limit state, compatibility of the deformations under elastic or elastic-plastic conditions should be considered.

(4) The following methods of analysis (see 2.2) should be used for the calculation of the design stresses and stress resultants when checking LS2:

? expressions in Annex C;

? elastic analysis (LA or GNA);

? MNA or GMNA and find plastic strains.

(5) Low cycle fatigue failure may be assumed to be prevented if the procedures set out in this standard are adopted.

tiffen Eurocode3-1-6

Page 19

EN 1993-1-6: 20xx

4.1.3 LS3: Buckling

(1) The limit state of buckling shall be taken as the condition in which all or part of the structure suddenly develops large displacements normal to the shell surface, caused by loss of stability under compressive membrane or shear membrane stresses in the shell wall, leading to inability to sustain any increase in the stress resultants, possibly causing catastrophic failure.

(2) The following methods of analysis (see 2.2), as appropriate, should be used for the calculation of the design stresses and stress resultants when checking LS3:

? membrane theory for axisymmetric conditions only (for exceptions, see relevant application parts of EN 1993)

? expressions in Annex A;

? linear elastic analysis (LA), which is a minimum requirement for stress analysis under general loading conditions (unless the load case is given in Annex A);

? linear elastic bifurcation analysis (LBA), which is required for shells under general loading conditions if the critical buckling resistance is to be used;

? materially nonlinear analysis (MNA), which is required for shells under general loading conditions if the reference plastic resistance is to be used;

? GMNIA, coupled with MNA, LBA and GMNA, using appropriate imperfections and calculated calibration factors.

(3) All relevant combinations of extreme loads causing compressive membrane or shear membrane stresses in the shell shall be accounted for when checking LS3.

(4) Because the strength under limit state LS3 depends strongly on the quality of construction, the strength assessment shall take account of the associated requirements for fabrication tolerances.

NOTE: For this purpose, three fabrication quality classes are set out in section 8.

4.1.4 LS4: Fatigue

(1) The limit state of fatigue shall be taken as the condition in which repeated cycles of increasing and decreasing stress lead to the development of a fatigue crack.

(2) The following methods of analysis (see 2.2) should be used for the calculation of the design stresses and stress resultants when checking LS4:

? expressions in Annex C, using stress concentration factors;

? elastic analysis (LA or GNA), using stress concentration factors.

(3) All variable actions that will be applied with more than Nf cycles in the life of the structure according to the relevant action spectrum in EN 1991 in accordance with the appropriate application part of EN 1993-3 or EN 1993-4, should be accounted for when checking LS4.

NOTE: The National Annex may choose the value of Nf . The value Nf = 10 000 is recommended.

4.2 Design concepts for the limit states design of shells

4.2.1 General

(1) The limit state verification should be carried out using one of the following:

? stress design;

? direct design by application of standard expressions;

? design by global numerical analysis (for example, by means of computer programs such as those based on the finite element method).

(2) Account should be taken of the fact that elasto-plastic material responses induced by different stress components in the shell have different effects on the failure modes and the ultimate limit states. The stress components should therefore be placed in stress categories with different limits. Stresses that develop to meet equilibrium requirements should be treated as more significant than stresses that are induced by the compatibility of deformations normal to the shell. Local stresses caused by notch effects in construction details may be assumed to have a negligibly small influence on the resistance to static loading.

扩展:eurocode3 中文版 / eurocode 3 / eurocode3 中文

tiffen Eurocode3-1-6

Page 20

EN 1993-1-6: 20xx

(3) The categories distinguished in the stress design should be primary, secondary and local stresses. Primary and secondary stress states may be replaced by stress resultants where appropriate.

(4) In a global analysis, the primary and secondary stress states should be replaced by the limit load and the strain range for cyclic loading.

(5) In general, it may be assumed that primary stress states control LS1, whereas secondary stress states affect LS2 and LS3 and local stresses govern LS4.

4.2.2 Stress design

4.2.2.1 General

(1) Where the stress design approach is used, the limit states should be assessed in terms of three categories of stress: primary, secondary and local. The categorisation is performed, in general, on the von Mises equivalent stress at a point, but buckling stresses cannot be assessed using this value.

4.2.2.2 Primary stresses

(1) The primary stresses should be taken as the stress system required for equilibrium with the imposed loading. They may be calculated from any realistic statically admissible determinate system. The limit state should be deemed to be reached when the primary stress reaches the yield strength throughout the full thickness of the wall at a sufficient number of points, such that only the strain hardening reserve or a change of geometry would lead to an increase in the resistance of the structure.

(2) The calculation of primary stresses should be based on any system of stress resultants, consistent with the requirements of equilibrium of the structure. It may also take into account the benefits of plasticity theory. Alternatively, since linear elastic analysis satisfies equilibrium requirements, its predictions may also be used as a representation of the limit state. Any of the methods given in 5.3 may be applied.

(3) Because limit state design allows for full plastification of the cross-section, the primary stresses due to bending moments may be calculated on the basis of the plastic section modulus (see 6.2.1). Where there is interaction between stress resultants in the cross-section, interaction rules based on the von Mises yield criterion may be applied.

(4) The primary stresses should be limited by the design value of the yield strength (see section 6).

4.2.2.3 Secondary stresses

(1) In statically indeterminate structures, account should be taken of the secondary stresses, induced by internal compatibility and compatibility with the boundary conditions, that are caused by imposed loading or imposed displacements (temperature, prestressing, settlement, shrinkage).

NOTE: As the von Mises yield condition is approached, the displacements of the structure increase without further increase in the stress state.

(2) Where cyclic loading causes plasticity, and several loading cycles occur, consideration should be given to the possible reduction of resistance caused by the secondary stresses. Where the cyclic loading is of such a magnitude that yielding occurs at both the maximum load and again on unloading, account should be taken of a possible failure by cyclic plasticity associated with the secondary stresses.

(3) If the stress calculation is carried out using a linear elastic analysis that allows for all relevant compatibility conditions (effects at boundaries, junctions, variations in wall thickness etc.), the stresses that vary linearly through the thickness may be taken as the sum of the primary and secondary stresses and used in an assessment involving the von Mises yield criterion (see 6.2).

NOTE: The secondary stresses are never needed separately from the primary stresses.

(4) The secondary stresses should be limited as follows:

? The sum of the primary and secondary stresses (including bending stresses) should be limited to 2fy for the condition of cyclic plasticity (LS2: see section 7);

? The membrane component of the sum of the primary and secondary stresses should be limited by the design buckling resistance (LS3: see section 8).

tiffen Eurocode3-1-6

Page 21

EN 1993-1-6: 20xx

? The sum of the primary and secondary stresses (including bending stresses) should be limited to the fatigue resistance (LS4: see section 9).

4.2.2.4 Local stresses

(1) The highly localised stresses associated with stress raisers in the shell wall due to notch effects (holes, welds, stepped walls, attachments, and joints) should be taken into account in a fatigue assessment (LS4).

(2) For construction details given in EN 1993-1-9, the fatigue design may be based on the nominal linear elastic stresses (sum of the primary and secondary stresses) at the relevant point. For all other details, the local stresses may be calculated by applying stress concentration factors (notch factors) to the stresses calculated using a linear elastic stress analysis.

扩展:eurocode3 中文版 / eurocode 3 / eurocode3 中文

(3) The local stresses should be limited according to the requirements for fatigue (LS4) set out in section 9.

4.2.3 Direct design

(1) Where direct design is used, the limit states may be represented by standard expressions that have been derived from either membrane theory, plastic mechanism theory or linear elastic analysis.

(2) The membrane theory expressions given in Annex A may be used to determine the primary stresses needed for assessing LS1 and LS3.

(3) The expressions for plastic design given in Annex B may be used to determine the plastic limit loads needed for assessing LS1.

(4) The expressions for linear elastic analysis given in Annex C may be used to determine stresses of the primary plus secondary stress type needed for assessing LS2 and LS4. An LS3 assessment may be based on the membrane part of these expressions.

4.2.4 Design by global numerical analysis

(1) Where a global numerical analysis is used, the assessment of the limit states shall be carried out using one of the alternative types of analysis specified in 2.2 (but not membrane theory analysis) applied to the complete structure.

(2) Linear elastic analysis (LA) may be used to determine stresses or stress resultants, for use in assessing LS2 and LS4. The membrane parts of the stresses may be used in assessing LS3. LS1 may be assessed using LA, but LA only gives an approximate estimate and its results should be interpreted as set out in section 5.

(3) Linear elastic bifurcation analysis (LBA) may be used to determine the elastic critical buckling resistance of the structure, for use in assessing LS3.

(4) A materially nonlinear analysis (MNA) may be used to determine plastic limit loads, that may be used for assessing LS1. Under a cyclic loading history, an MNA analysis may be used to determine plastic strain incremental changes, for use in assessing LS2. An MNA analysis may be used to determine the reference plastic load required as part of the assessment of LS3.

(5) Geometrically nonlinear elastic analyses (GNA and GNIA) include consideration of the deformations of the structure, but none of the design methodologies of section 8 permit these to be used without a GMNIA analysis. A GNA analysis may be used to determine the elastic buckling load of the perfect structure. A GNIA analysis may be used to determine the elastic buckling load of the imperfect structure.

(6) Geometrically and materially nonlinear analysis may be used to determine collapse loads for the imperfect structure (GMNIA). These collapse loads may be used for assessing LS3. For design purposes the analysis should be interpreted as detailed in 6.3 and 8.7 respectively. Under a cyclic loading history, the plastic strain incremental changes for the perfect structure may be used for assessing LS2.

tiffen Eurocode3-1-6

Page 22

EN 1993-1-6: 20xx

5 Stress resultants and stresses in shells

5.1 Stress resultants in the shell

(1) In principle, the eight stress resultants in the shell wall at any point should be calculated and the assessment of the shell with respect to each limit state should take all of them into account. However, the shear stresses τxn, τθn due to the transverse shear forces qxn, qθn are insignificant compared with the other components of stress in almost all practical cases, so they may usually be neglected in design.

(2) Accordingly, for most design purposes, the evaluation of the limit states may be made using only the six stress resultants in the shell wall nx, nθ, nxθ, mx, mθ, mxθ. Where the structure is axisymmetric and subject only to axisymmetric loading and support, only nx, nθ, mx and mθ need be used.

(3) If any uncertainty arises concerning the stress to be used in any of the limit state verifications, the von Mises equivalent stress on the shell surface should be used.

5.2 Modelling of the shell for analysis

5.2.1 Geometry

(1) The shell shall be represented by its middle surface.

(2) The radius of curvature shall be taken as the nominal radius of curvature. Imperfections shall be neglected, except as set out in section 8 (LS3 buckling limit state).

(3) An assembly of shell segments shall not be subdivided into separate segments for analysis unless the boundary conditions for each segment are chosen in such as way as to represent interactions between them in a conservative manner.

(4) A base ring intended to transfer local support forces into the shell shall not be separated from the shell it supports in an assessment of limit state LS3.

(5) Eccentricities and steps in the shell middle surface shall be included in the analysis model if they induce significant bending effects as a result of the membrane stress resultants following an eccentric path.

(6) At junctions between shell segments, any eccentricity between the middle surfaces of the shell segments shall be considered in the modelling.

扩展:eurocode3 中文版 / eurocode 3 / eurocode3 中文

(7) A ring stiffener should be treated as a separate structural component of the shell, except where the spacing of the rings is closer than 1,5 .

(8) A shell that has discrete stringer stiffeners attached to it may be treated as an orthotropic uniform shell, provided that the stringer stiffeners are no further apart than 5 .

(9) A shell that is corrugated (vertically or horizontally) may be treated as an orthotropic uniform shell provided that the corrugation wavelength is less than 0,5 .

(10) A hole in the shell may be neglected in the modelling provided its largest dimension is smaller than 0,5 .

(11) The overall stability of the complete structure should be verified as detailed in EN 1993 Parts 3.1, 3.2, 4.1,

4.2 or 4.3 as appropriate.

5.2.2 Boundary conditions

(1) The appropriate boundary conditions should be used in analyses for the assessment of limit states according to the conditions shown in table 5.1. For the special conditions needed for buckling calculations, reference should be made to 8.4.

(2) Rotational restraints at shell boundaries may be neglected in modelling for limit state LS1, but should be included in modelling for limit states LS2 and LS4. For short shells (see Annex D), the rotational restraint should be included for limit state LS3.

tiffen Eurocode3-1-6

Page 23

EN 1993-1-6: 20xx

(3) Support boundary conditions should be checked to ensure that they do not cause excessive non-uniformity of transmitted forces or introduced forces that are eccentric to the shell middle surface. Reference should be made to the relevant EN 1993 application parts for the detailed application of this rule to silos and tanks.

(4) When a global numerical analysis is used, the boundary condition for the normal displacement w should also be used for the circumferential displacement v, except where special circumstances make this inappropriate.

Table 5.1: Boundary conditions for shells

condition

code

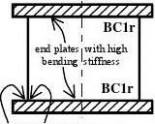

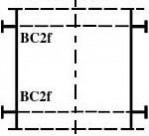

BC1r term Clamped displacements displacements rotation radially restrained meridionally restrained w = 0 u = 0 βφ = 0 rotation restrained

w = 0 u = 0 BC1f meridionally restrained βφ ≠ 0 rotation free

w = 0 BC2r meridionally free u ≠ 0 βφ = 0 rotation restrained

w = 0 BC2f Pinned meridionally free u ≠ 0 βφ ≠ 0 rotation free

Free edge meridionally free BC3 w ≠ 0 u ≠ 0 βφ ≠ 0 rotation free

NOTE: The circumferential displacement v is closely linked to the displacement w normal to the surface so separate boundary conditions are not identified in paragraph (3) for these two parameters.

5.2.3 Actions and environmental influences

(1) Actions shall all be assumed to act at the shell middle surface. Eccentricities of load shall be represented by static equivalent forces and moments at the shell middle surface.

(2) Local actions and local patches of action shall not be represented by equivalent uniform loads except as detailed in section 8 (LS3 for buckling).

(3) The modelling should account for whichever of the following are relevant:

? local settlement under shell walls;

? local settlement under discrete supports;

? uniformity of support of structure;

? thermal differentials from one side of the structure to the other;

? thermal differentials from inside to outside the structure;

? wind effects on openings and penetrations;

? interaction of wind effects on groups of structures;

? connections to other structures;

? conditions during erection.

5.2.4 Stress resultants and stresses

(1) Provided that the radius to thickness ratio is greater than (r/t)min, the curvature of the shell may be ignored when calculating the stress resultants from the stresses in the shell wall.

NOTE: The National Annex may choose the value of (r/t)min. The value (r/t)min = 25 is recommended.

tiffen Eurocode3-1-6

Page 24

EN 1993-1-6: 20xx

5.3 Types of analysis

(1) The design should be based on one or more of the types of analysis given in table 5.2. Reference should be made to 2.2 for the conditions governing the use of each type of analysis.

Table 5.2: Types of shell analysis

Type of analysis

Membrane theory of shells

Linear elastic shell analysis (LA)

Linear elastic bifurcation analysis (LBA) Shell theory membrane equilibrium Material law not applicable Shell geometry perfect

Geometrically non-linear elastic analysis

(GNA)

Geometrically and materially non-linear

analysis (GMNA)

Geometrically non-linear elastic analysis

with imperfections (GNIA)

Geometrically and materially non-linear

analysis with imperfections (GMNIA)

linear bending and stretching linear bending and stretching

tiffen Eurocode3-1-6

Page 25

扩展:eurocode3 中文版 / eurocode 3 / eurocode3 中文

EN 1993-1-6: 20xx

6 Plastic limit state (LS1)

6.1 Design values of actions

(1) The design values of the actions shall be based on the most adverse relevant load combination (including the relevant γF and ψ factors).

(2) Only those actions that represent loads affecting the equilibrium of the structure need be included.

6.2 Stress design

6.2.1 Design values of stresses

(1) Although stress design is based on an elastic analysis and therefore cannot accurately predict the plastic limit state, it may be used, on the basis of the lower bound theorem, to provide a conservative assessment of the plastic collapse resistance which is used to represent the plastic limit state (see 4.1.1).

(2) The Ilyushin yield criterion may be used, as detailed in (6), that comes closer to the true plastic collapse state than a simple elastic stress evaluation.

(3) At each point in the structure the design value of the stress σeq,Ed should be taken as the highest primary stress determined in a structural analysis that considers the laws of equilibrium between imposed design load and internal forces and moments.

(4) The primary stress may be taken as the maximum value of the stresses required for equilibrium with the applied loads at a point or along a line in the shell structure.

(5) Where a membrane theory analysis is used, the resulting two dimensional field of stress resultants nx,Ed, nθ,Ed and nxθ,Ed may be represented by the equivalent design stress σeq,Ed obtained from:

1σeq,Edtnx,Ed + nθ,Ed ? nx,Ed nθ,Ed + 3nxθ,Ed. ... (6.1)

(6) Where an LA or GNA analysis is used, the resulting two dimensional field of primary stresses may be represented by the von Mises equivalent design stress: σeq,Ed =σx,Ed + σθ,Ed ? σx,Ed σθ,Ed + 3(τxθ,Ed + τxn,Ed + τθn,Ed) in which:

nmσx,Ed t(t / 4).

nmτxθ t(t / 4).

NOTE1: The above expressions give a simplified conservative equivalent stress for design purposes.

NOTE2: The values of τxn,Ed and τθn,Ed are usually very small and do not affect the plastic resistance, so they may generally be ignored.

6.2.2 Design values of resistance

(1) The von Mises design strength should be taken from:

feq,Rd = fy / γM0

(2) ... (6.5) , nmσθ,Ed t (t / 4).q, τ tq , τθt... (6.3) (6.4) ... The partial factor for resistance γM0 should be taken from the relevant application standard.

tiffen Eurocode3-1-6

Page 26

EN 1993-1-6: 20xx

(3) Where no application standard exists for the form of construction involved, or the application standard does not define the relevant values of γM0, the value of γM0 should be taken from EN 1993-1-1.

(4) The effect of fastener holes should be taken into account in accordance with 6.2.3 of EN 1993-1-1 for tension and 6.2.4 of EN 1993-1-1 for compression. For the tension check, the resistance should be based on the design value of the ultimate strength fud.

6.2.3 Stress limitation

(1) In every verification of this limit state, the design stresses should satisfy the condition:

σeq,Ed ≤ feq,Rd ... (6.6)

6.3 Design by global numerical MNA or GMNA analysis

(1) The design plastic limit resistance shall be determined as a load factor R applied to the design values of the combination of actions for the relevant load case.

(2) The design values of the actions FEd should be determined as detailed in 6.1. The relevant load cases should be formed according to the required load combinations.

(3) In an MNA or GMNA analysis based on the design yield strength fyd, the shell should be subject to the design values of the load cases detailed in (2), progressively increased by the load ratio R until the plastic limit condition is reached.

(4) Where an MNA analysis is used, the load ratio RMNA may be taken as the largest value attained in the analysis, ignoring the effect of strain hardening.

(5) Where a GMNA analysis is used, if the analysis predicts a maximum load followed by a descending path, the maximum value should be used to determine the load ratio RGMNA. Where a GMNA analysis does not predict a maximum load, but produces a progressively rising action-displacement relationship without strain hardening of the material, the load ratio RGMNA should be taken as no larger than the value at which the maximum von Mises equivalent plastic strain in the structure attains the value εmps = nmps (fyd / E).

NOTE: The National Annex may choose the value of nmps. The value nmps = 50 is recommended.

(6) The result of the analysis should produce a load ratio R greater than 1,0: that is, it should satisfy the condition:

FEd ≤ FRd

in which:

FRd = R FEd.

... (6.8) ... (6.7)

6.4 Direct design

(1) For each shell segment in the structure represented by a basic loading case as given by Annex A, the highest von Mises membrane stress σeq,Ed determined under the design values of the actions FEd should be limited to the stress resistance according to 6.2.2.

扩展:eurocode3 中文版 / eurocode 3 / eurocode3 中文

(2) For each shell or plate segment in the structure represented by a basic load case as given in Annex B, the design value of the actions FEd should not exceed the load resistance FRd based on the design yield strength fyd.

tiffen Eurocode3-1-6

Page 27

EN 1993-1-6: 20xx

(3) Where net section failure at a bolted joint is a design criterion, the design value of the actions FEd should be determined for each joint. Where the stress can be represented by a basic load case as given in Annex A, and where the resulting stress state involves only membrane stresses, FEd should not exceed the load resistance FRd based on the design ultimate strength fud (see 6.2.2(4)).

tiffen Eurocode3-1-6

Page 28

EN 1993-1-6: 20xx

7 Cyclic plasticity limit state (LS2)

7.1 Design values of actions

(1) Unless an improved definition is used, the design values of the actions for each load case should be chosen as the characteristic values of those parts of the total actions that are expected to be applied and removed more than three times in the design life of the structure.

(2) Where an elastic analysis or the expressions from Annex C are used, only the varying part of the actions between the extreme upper and lower values should be taken into account.

(3) Where a materially nonlinear computer analysis is used, the varying part of the actions between the extreme upper and lower values should be considered to act in the presence of coexistent fixed parts of the load.

7.2 Stress design

7.2.1 Design values of stress range

(1) The shell should be analysed using an LA or GNA analysis of the structure subject to the two extreme design values of the actions FEd. For each extreme load condition in the cyclic process, the stress components should be evaluated. From adjacent extremes in the cyclic process, the design values of the change in each stress component ?σx,Ed, ?σθ,Ed, ?τxθ,Ed on each shell surface and at any point in the structure should be determined. From these changes in stress, the design value of the von Mises equivalent stress change on each surface ?σeq,Ed,i should be found from:

=?σx,Ed ? ?σx,Ed ?σθ,Ed + ?σθ,Ed + 3?τxθ,Ed ?σeq,Ed,i ... (7.1)

(2) The design value of the stress range ?σeq,Ed should be taken as the largest change in the von Mises equivalent stress changes ?σeq,Ed,i, considering each shell surface in turn.

(3) At a junction between shell segments, where the analysis models the intersection of the middle surfaces and ignores the finite size of the junction, the stress range may be taken at the first physical point in the shell segment (as opposed to the value calculated at the intersection of the two middle surfaces).

NOTE: This allowance is relevant where the stress changes very rapidly close to the junction.

7.2.2 Design values of resistance

(1) The von Mises equivalent stress range resistance ?feq,Rd should be determined from:

?feq,Rd = 2 fyd

7.2.3 Stress range limitation

(1) In every verification of this limit state, the design stress range should satisfy: ... (7.2) (7.3) ?σeq,Ed ≤ ?feq,Rd ...

7.3 Design by global numerical MNA or GMNA analysis

7.3.1 Design values of total accumulated plastic strain

(1) Where a materially nonlinear global numerical analysis (MNA or GMNA) is used, the shell should be subject to the design values of the varying and fixed actions detailed in 7.1.

(2) The total accumulated von Mises equivalent plastic strain εp,eq.Ed at the end of the design life of the structure should be assessed.

tiffen Eurocode3-1-6

Page 29

EN 1993-1-6: 20xx

(3) The total accumulated von Mises equivalent plastic strain may be determined using an analysis that models all cycles of loading during the design life.

(4) Unless a more refined analysis is carried out, the total accumulated von Mises equivalent plastic strain εp,eq,Ed may be determined from:

εp,eq,Ed = n ?εp,eq,Ed

where:

n is the number of cycles of loading in the design life of the structure;

?εp,eq,Ed is the largest increment in the von Mises equivalent plastic strain during one complete

load cycle at any point in the structure, occurring after the third cycle.

(5) It may be assumed that “at any point in the structure” means at any point not closer to a notch or local discontinuity than the thickest adjacent plate thickness.

NOTE 1: It is usual to use an MNA analysis for this purpose.

NOTE 2: The National Annex may give recommendations for a more refined analysis.

7.3.2 Total accumulated plastic strain limitation

(1) Unless a more sophisticated low cycle fatigue assessment is undertaken, the design value of the total accumulated von Mises equivalent plastic strain εp,eq,Ed should satisfy the condition:

扩展:eurocode3 中文版 / eurocode 3 / eurocode3 中文

εp,eq,Ed ≤ np,eq (fyd / E)

... (7.4) ... (7.5) NOTE: The National Annex may choose the value of np,eq. The value np,eq = 5 is recommended.

7.4 Direct design

(1) For each shell segment in the structure, represented by a basic loading case as given by Annex C, the highest von Mises equivalent stress range ?σeq,Ed considering both shell surfaces under the design values of the actions FEd should be determined using the relevant expressions given in Annex C. The further assessment procedure should be as detailed in 7.2.

tiffen Eurocode3-1-6

Page 30

EN 1993-1-6: 20xx

8 Buckling limit state (LS3)

8.1 Design values of actions

(1) All relevant combinations of actions causing compressive membrane stresses or shear membrane stresses in the shell wall shall be taken into account.

8.2 Special definitions and symbols

(1) Reference should be made to the special definitions of terms concerning buckling in 1.3.5.

(2) In addition to the symbols defined in 1.4, additional symbols should be used in this section 8 as set out in (3) and (4).

(3) The stress resultant and stress quantities should be taken as follows:

nx,Ed, σx,Ed are the design values of the acting buckling-relevant meridional membrane stress

resultant and stress (positive when compression);

nθ,Ed, σθ,Ed are the design values of the acting buckling-relevant circumferential membrane (hoop) stress resultant and stress (positive when compression);

nxθ,Ed, τxθ,Ed are the design values of the acting buckling-relevant shear membrane stress resultant and stress.

(4) Buckling resistance parameters for use in stress design:

σx,Rcr is the meridional critical buckling stress;

σθ,Rcr is the circumferential critical buckling stress;

τxθ,Rcr is the shear critical buckling stress;

σx,Rk is the meridional characteristic buckling stress;

σθ,Rk is the circumferential characteristic buckling stress;

τxθ,Rk is the shear characteristic buckling stress;

σx,Rd is the meridional design buckling stress;

σθ,Rd is the circumferential design buckling stress;

τxθ,Rd is the shear design buckling stress.

that detailed in EN1993-1-1. NOTE: This is a special convention for shell design that differs from

(5) The sign convention for use with LS3 should be taken as compression positive for meridional and circumferential stresses and stress resultants.

8.3 Buckling-relevant boundary conditions

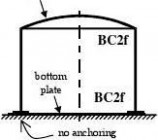

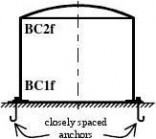

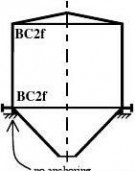

(1) For the buckling limit state, special attention should be paid to the boundary conditions which are relevant to the incremental displacements of buckling (as opposed to pre-buckling displacements). Examples of relevant boundary conditions are shown in figure 8.1, in which the codes of Table 5.1 are used.

8.4 Buckling-relevant geometrical tolerances

8.4.1 General

(1) Unless specific buckling-relevant geometrical tolerances are given in the relevant EN 1993 application parts, the following tolerance limits should be observed if LS3 is one of the ultimate limit states to be considered.

NOTE 1: The characteristic buckling stresses determined hereafter include imperfections that are based on the amplitudes and forms of geometric tolerances that are expected to be met during execution.

tiffen Eurocode3-1-6

Page 31

EN 1993-1-6: 20xx

NOTE 2: The geometric tolerances given here are those that are known to have a large impact on the safety of the structure.

(2) The fabrication tolerance quality class should be chosen as Class A, Class B or Class C according to the tolerance definitions in 8.4.2, 8.4.3, 8.4.4 and 8.4.5. The description of each class relates only to the strength evaluation.

NOTE: Until there is an execution standard that classifies geometrical tolerances according to safety considerations, these tolerances are intended to be adopted in execution.

(3) Each of the imperfection types should be classified separately: the lowest class should then govern the entire design.

(4) The different tolerance types may each be treated independently, and no interactions need normally be considered.

(5) It should be established by representative sample checks that the measurements of the geometrical imperfections stay within the geometrical tolerances stipulated in 8.4.2 to 8.4.4.

(6) Sample imperfection measurements should be undertaken on the unloaded structure (except for self weight) and, where possible, with the operational boundary conditions.

(7) If the measurements of geometrical imperfections do not satisfy the geometrical tolerances stated in 8.4.2 to 8.4.4, any correction steps, such as by straightening, should be investigated and decided individually.

NOTE: Before a decision is made in favour of straightening to reduce geometric imperfections, it should be noted that this can cause additional residual stresses. The degree to which the design buckling resistances are utilised in the design should also be considered.

扩展:eurocode3 中文版 / eurocode 3 / eurocode3 中文

a) tank without anchors

b) silo without anchors

c) tank with anchors

d) open tank with anchors e) laboratory experiment

f) section of long ring-stiffened cylinder

Figure 8.1: Schematic examples of boundary conditions for limit state LS3

tiffen Eurocode3-1-6

Page 32

EN 1993-1-6: 20xx

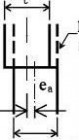

8.4.2 Out-of-roundness tolerance (1)

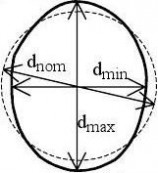

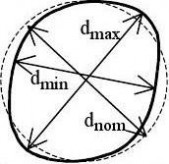

The out-of-roundness should be assessed in terms of the parameter Ur (see figure 8.2) given by:

d ? dUr =

dnom

where:

dmax dmin dnom

is the maximum measured internal diameter, is the minimum measured internal diameter, is the nominal internal diameter.

... (8.1)

(2) The measured internal diameter from a given point should be taken as the largest distance across the shell from the point to any other internal point at the same axial coordinate. An appropriate number of diameters should be measured to identify the maximum and minimum values.

b) unsymmetrical

Figure 8.2: Measurement of diameters for assessment of out-of-roundness

(3)

The out-of-roundness parameter Ur should satisfy the condition:

Ur ≤ Ur,max

where:

Ur,max is the out-of-roundness tolerance parameter for the relevant fabrication tolerance quality

class.

NOTE: Values for the out-of-roundness tolerance parameter Ur,max may be obtained from the National Annex. The recommended values are given in Table 8.1.

... (8.2)

Table 8.1: Values for out-of-roundness tolerance parameter Ur,max

d ≤ 0,50m Fabrication Description tolerance quality class Class A Excellent 0,014

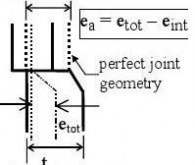

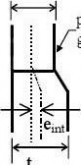

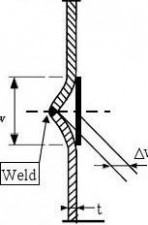

8.4.3 Accidental eccentricity tolerance

(1) At joints in shell walls perpendicular to membrane compressive forces, the accidental eccentricity should be evaluated from the measurable total eccentricity etot and the intended offset eint from:

0,50m < d < 1,25m Value of Ur,max

1,25m ≤ d

0,007 + 0,0093(1,25?d(8.3) ea = etot ? eint ...

where:

etot

eint

is the eccentricity between the middle surfaces of the joined plates (see figure 8.3c); is the intended offset between the middle surfaces of the joined plates (see figure 8.3b);

tiffen Eurocode3-1-6

Page 33

EN 1993-1-6: 20xx

ea

is the accidental eccentricity between the middle surfaces of the joined plates.

(2) The accidental eccentricity ea should satisfy the maximum permitted accidental eccentricity for the relevant fabrication tolerance quality class.

NOTE: Values for the maximum permitted accidental eccentricity may be obtained from the National Annex. The recommended values are given in Table 8.2.

Table 8.2: Values for maximum permitted accidental eccentricities